Beam frame structure of combined type house and assembly method thereof

An installation method and combined technology, which is applied in the direction of building construction and construction, can solve the problems of complex beam structure setting, difficulty in fixing upper and lower multi-layer structures, etc., and achieve the effects of simplified process, simple structure, and convenient manufacture and installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

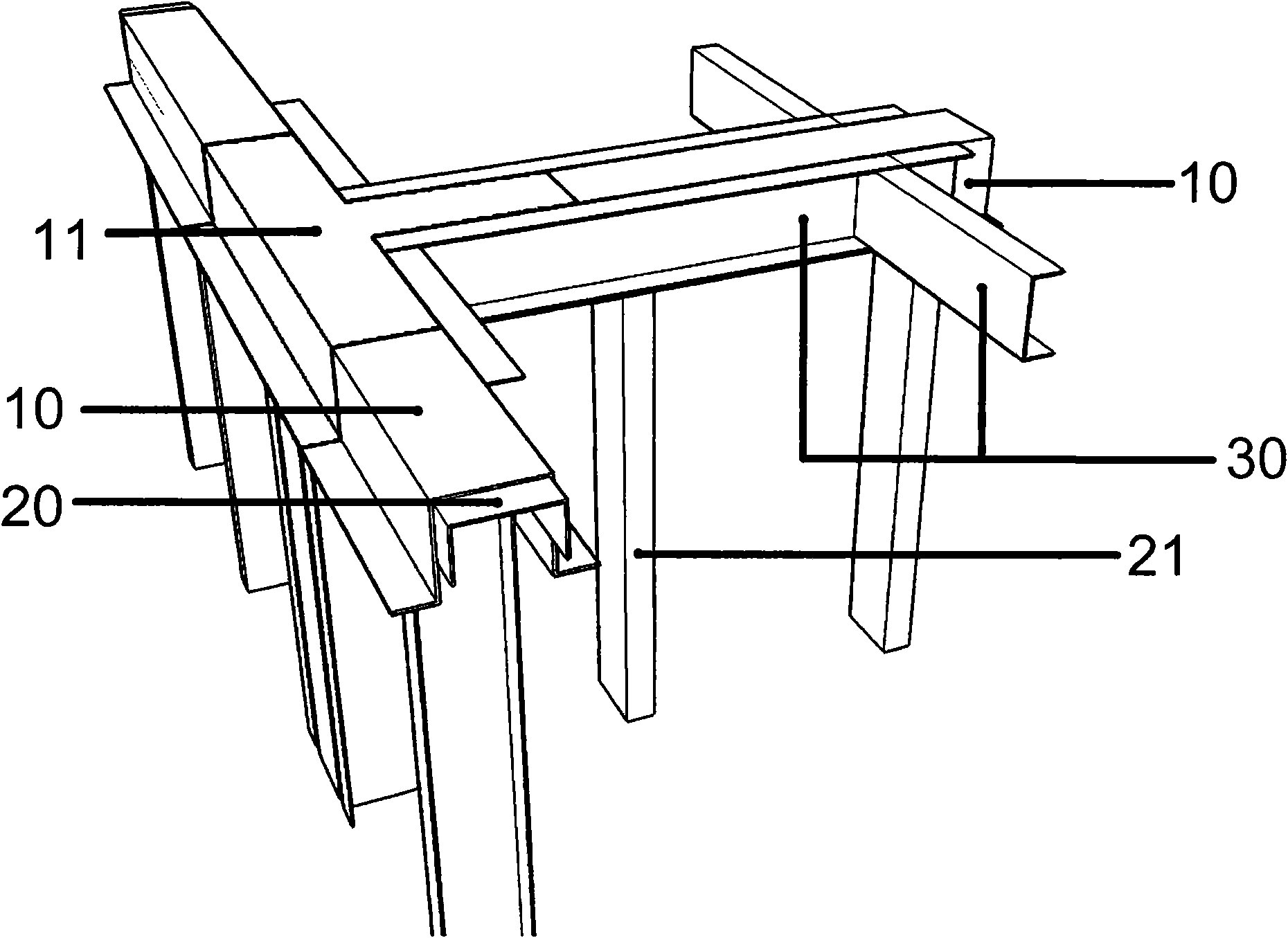

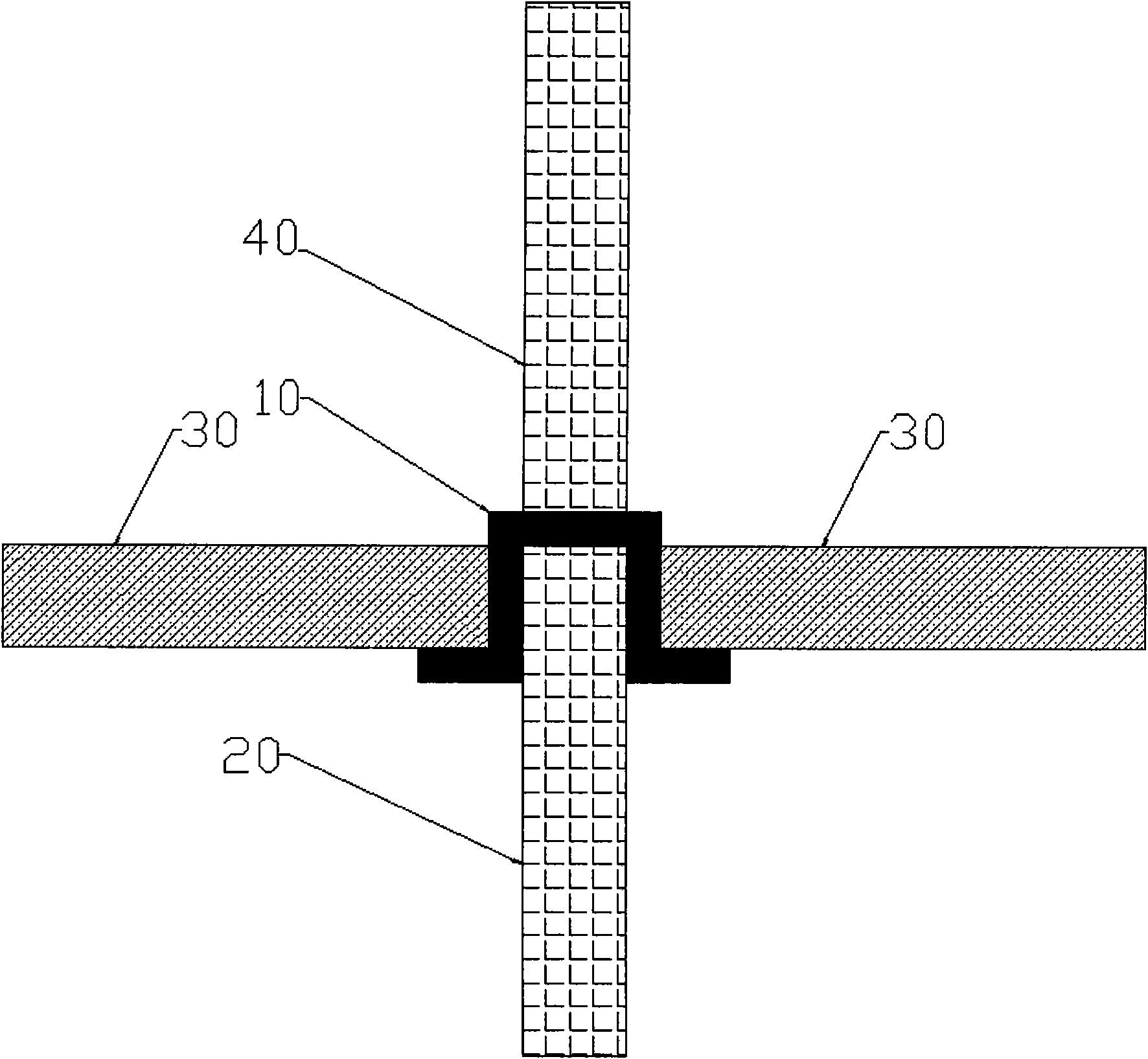

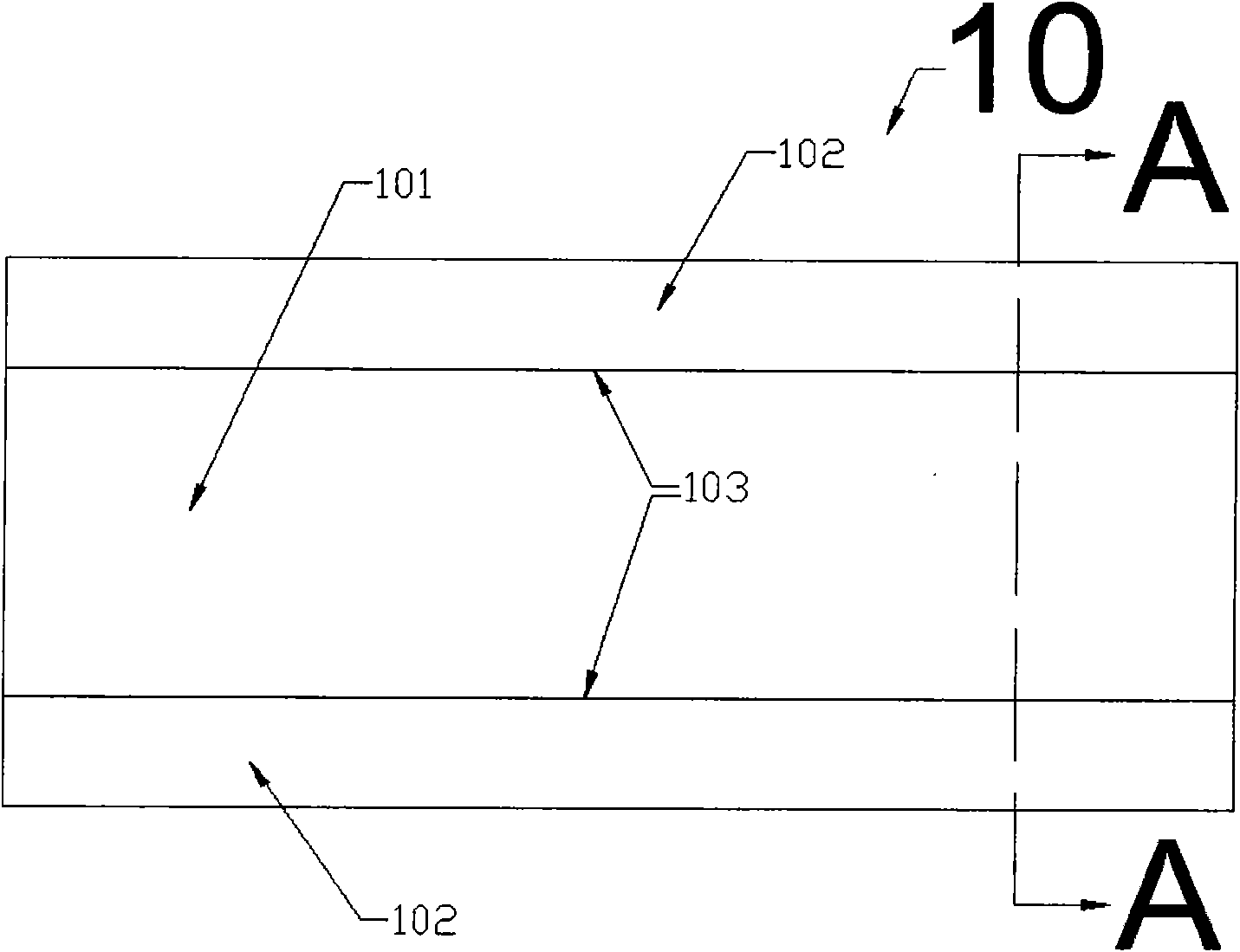

[0049] The invention provides a cold-formed thin-walled light steel wall system combined house that can be completed in the factory. It is manufactured industrially by the factory, and is composed of light steel, structural boards (OSB boards, CCA boards), gypsum boards, and thermal insulation and waterproof materials. The wall, base plate, floor slab and roof panel completed by bolt combination with external wall materials. Then the factory completes the assembly of the overall main structure, including the decoration and fixed objects, all heating, power supply, water supply and drainage systems are integrated in this main structure, and other walls only need to pre-fabricate wiring pipes, sockets and wires Connector. Each component of the combined house, including the main structure and other extensions, can be directly placed in the container after completion, and delivered to the destination for assembly. The finished house can reach a semi-permanent service life of more...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com