Intelligent transformer substation grounding network anti-corrosion and monitoring system

A technology of intelligent substation and monitoring system, applied in the direction of material resistance, etc., can solve the problems of not considering the influence of environmental conditions protection parameters, no state sensor, large error between the calculated value and the actual value, etc., to achieve convenient and safe operation parameters, The effect of adjusting the working state and facilitating the current state of corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention closely combines the geographic location characteristics of the substation and the defects of the prior art, uses a potentiostat as the basis, and uses a computer as a data processing tool; on this basis, it develops an online detection function with the corrosion degree of the grounding grid, and an online detection of environmental conditions Function, data acquisition and processing function, 3G data and image wireless transmission function, intelligent substation grounding grid dedicated anti-corrosion cathodic protection system.

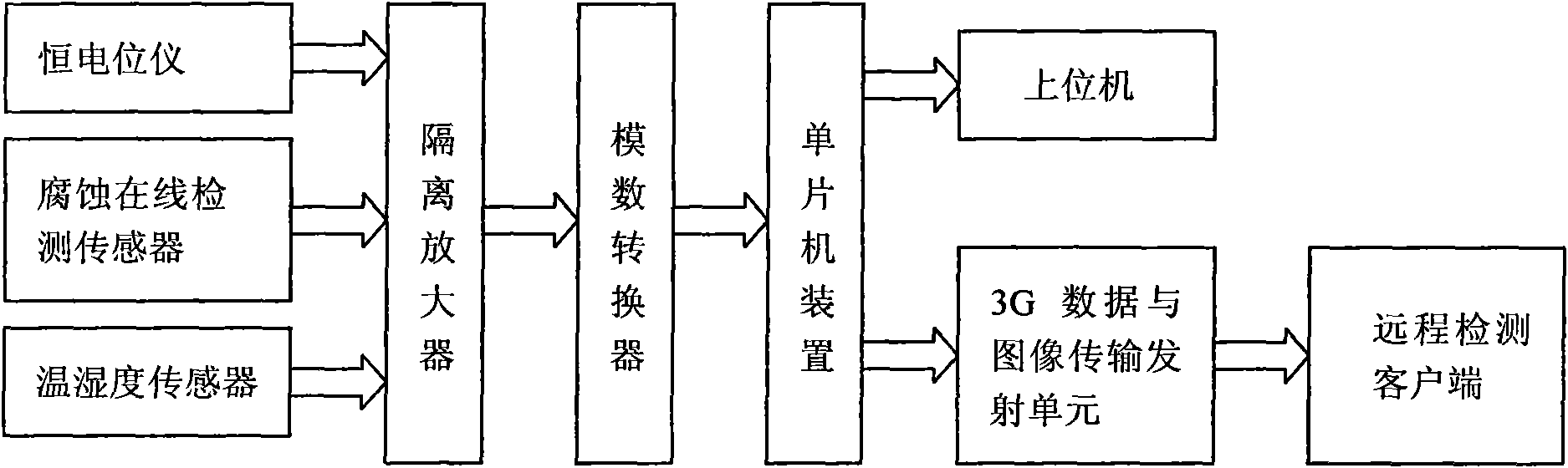

[0018] refer to figure 1 As shown, the system consists of a potentiostat, an online corrosion detector, a temperature and humidity sensor, an isolation amplifier, an analog-to-digital converter, a computer, a host computer, a 3G data and image transmission unit, and a remote detection client. Its connection mode is that the signals sent by the potentiostat, the corrosion online detector, and the temperature and humid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com