X-ray development material compound device, method and dressing

A composite device and composite head technology, applied in dressings, viscous dressings, etc., can solve the problems of unfavorable large-scale and diversified production, high energy consumption, unfavorable environmental protection, etc., and achieve a product that is not easy to fall off, consumes less energy, and is firmly composited Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described in detail below through specific embodiments in conjunction with the accompanying drawings.

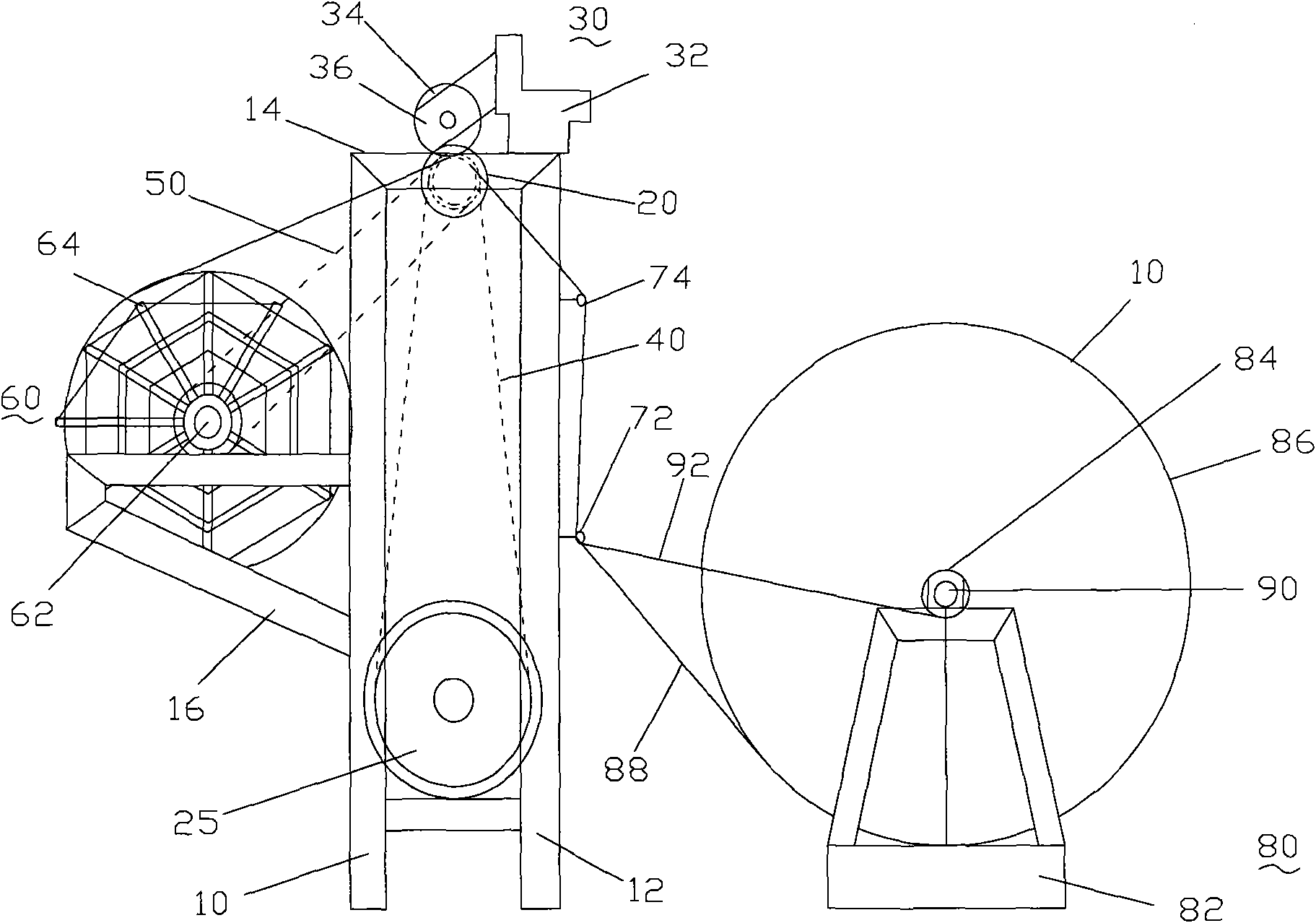

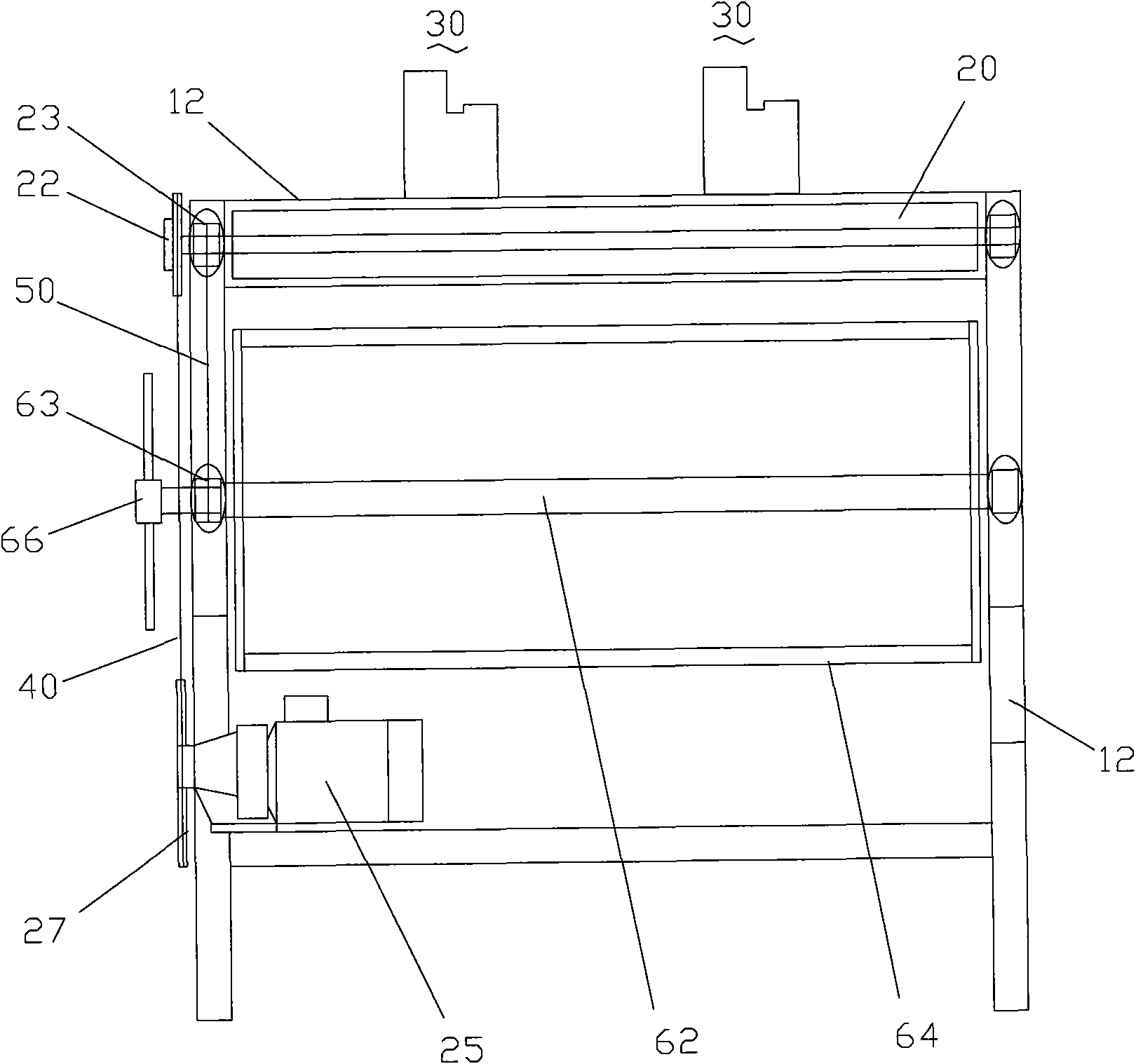

[0018] The present invention relates to an X-ray developing material compounding device, which combines at least one ultrasonic compounding head 30, and the ultrasonic compounding head 30 cooperates with the compounding pressure roller 20 on the device, and the dressing guided by the cloth guiding device through the compounding pressure roller 88 and X-ray developing material 92 carry out high-frequency mechanical compounding, and this device does not need larger heating elements, consumes less energy and is more environmentally friendly. Among them, the ultrasonic vibration of the composite head can not only effectively heat the X-ray imaging material 92 and the dressing 88, but also the X-ray imaging material 92 and the gauze or non-woven dressing 88 are pressed by high-frequency mechanical pressure on the composite pressure roll...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com