Wheel-side reducer with brake for bracket carrier

A technology of support truck and wheel side reducer, which is applied in the directions of rail brakes, transportation and packaging, railway car body parts, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with accompanying drawing:

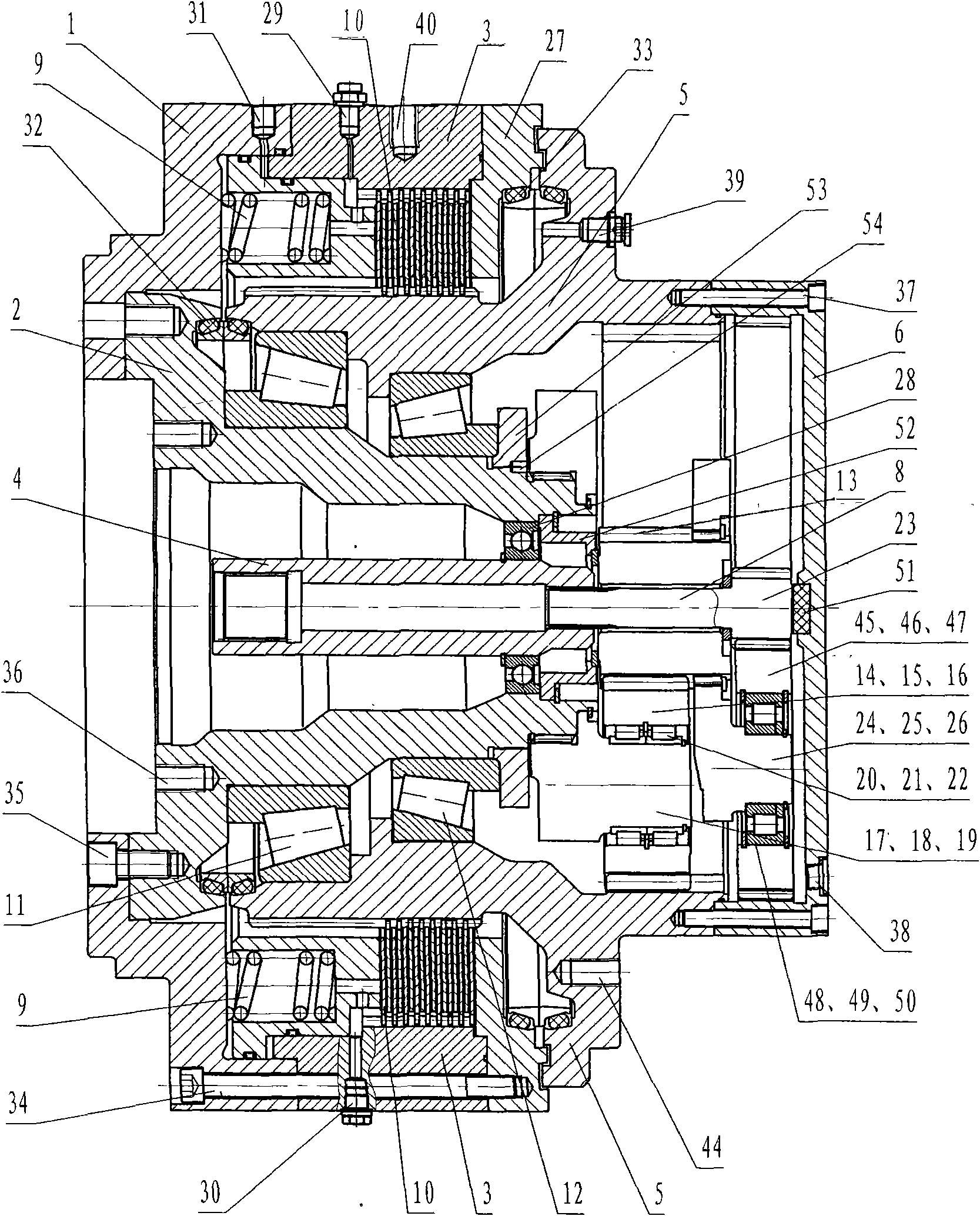

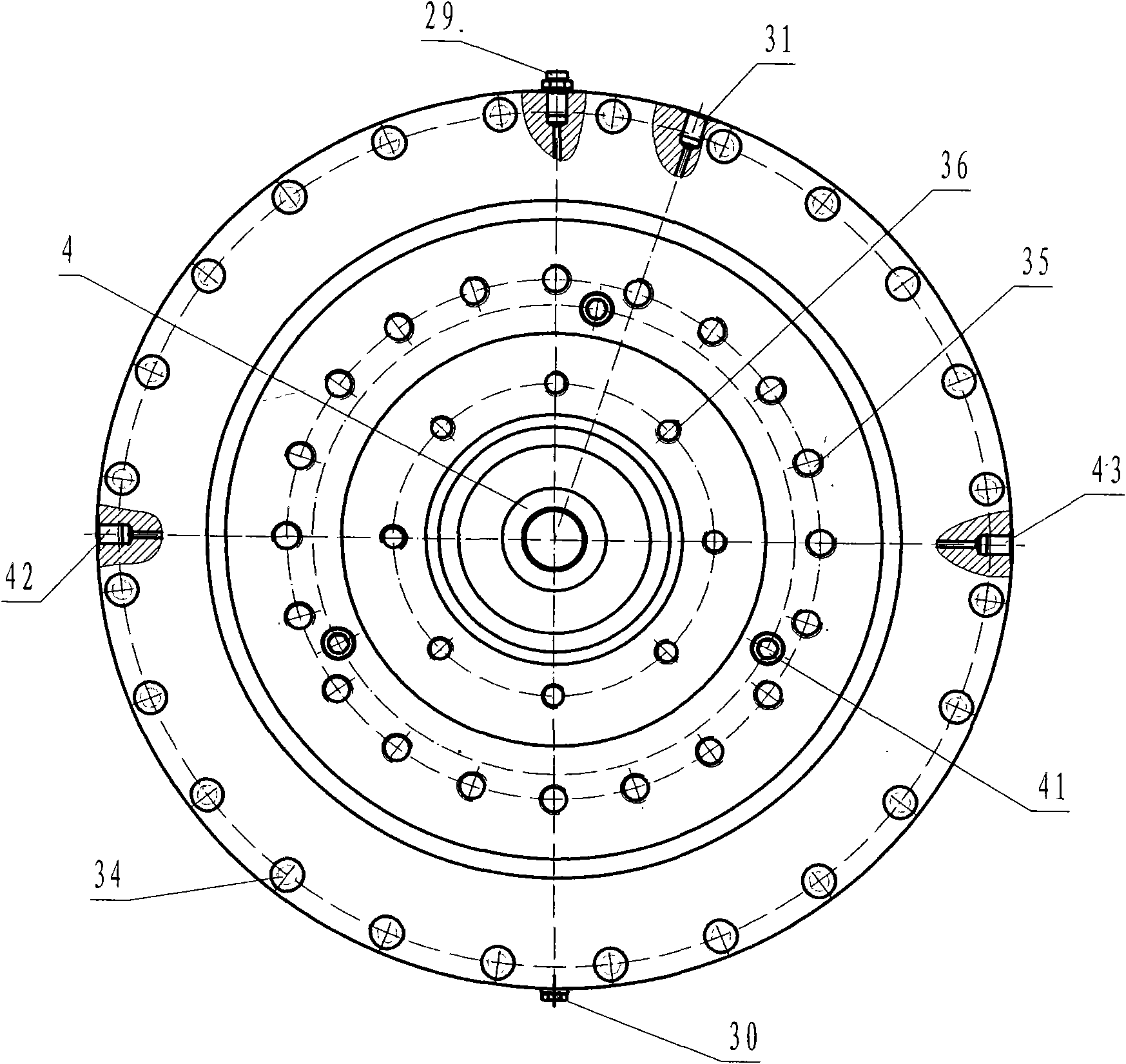

[0018] figure 1 , 2 Shown is the overall structure diagram of the wheel reducer with brake.

[0019] The position and connection relationship of each part must be correct and the installation should be firm.

[0020] The brake housing, inner bracket, outer bracket, outer jacket, inner ring gear, and end cover ring gear must be strong, friction-resistant, made of alloy structural steel, and hardened.

[0021] The spline shaft sleeve and the sun gear shaft should have good strength and high hardness, and should be made of alloy tool steel and hardened.

[0022] The brake spring is composed of 30 small springs to form an integral spring structure, which should be evenly elastic.

[0023] The friction plate is composed of 8 static friction plates and 9 dynamic friction plates. The friction effect is good. The wheel side reducer is a double planetary first and second stage r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com