Atmospheric plasma chemical processing method of WC and SiC optical molding molds

A plasma and chemical processing technology, applied in the field of plasma chemical processing, can solve the problems of reduced service life of the mold, subsurface damage, low processing efficiency, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

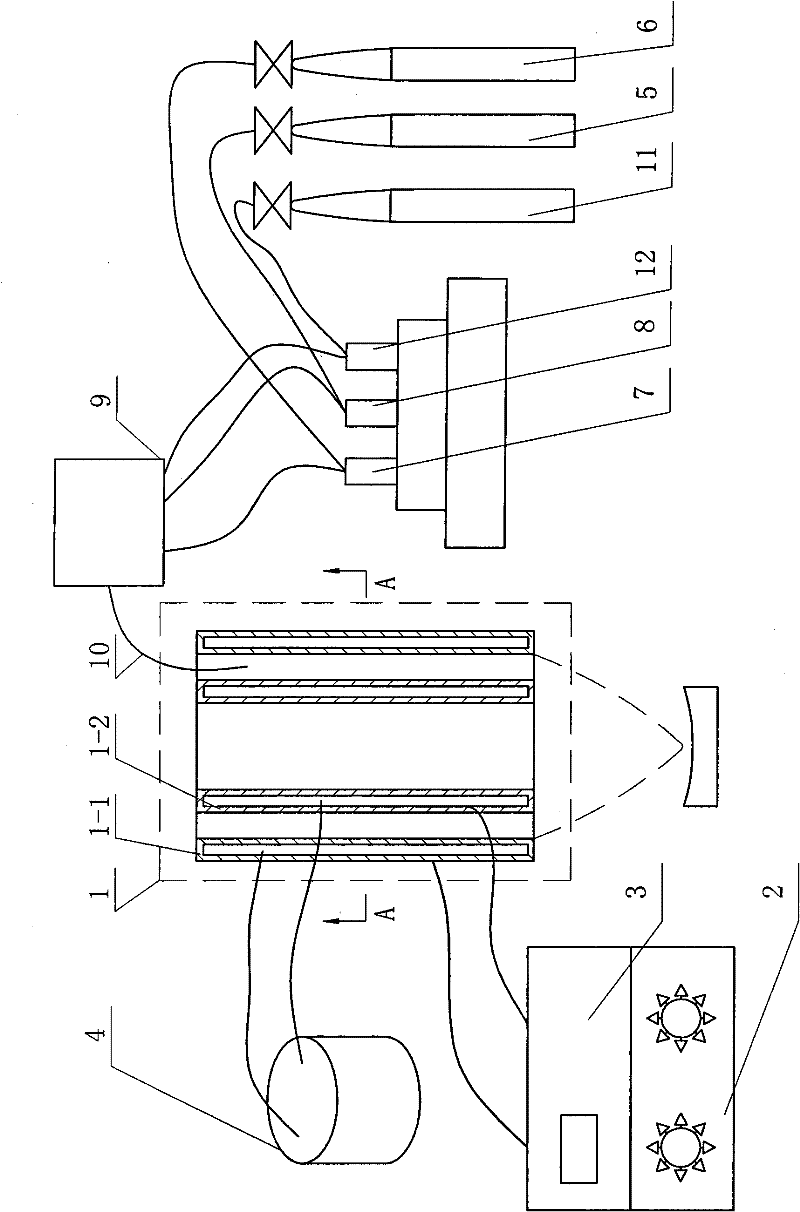

[0030] Specific implementation mode one: the following combination figure 1 , Figure 6 Describe this embodiment mode, the device that realizes the method of the present invention is by plasma generator 1, radio frequency power supply 2, impedance matcher 3, cooling water pump 4, plasma gas bottle 5, reaction gas bottle 6, first flow controller 7, the first Two flow controllers 8, a gas mixing chamber 9, a gas delivery pipe 10, an oxygen bottle 11 and a third flow controller 12 are formed,

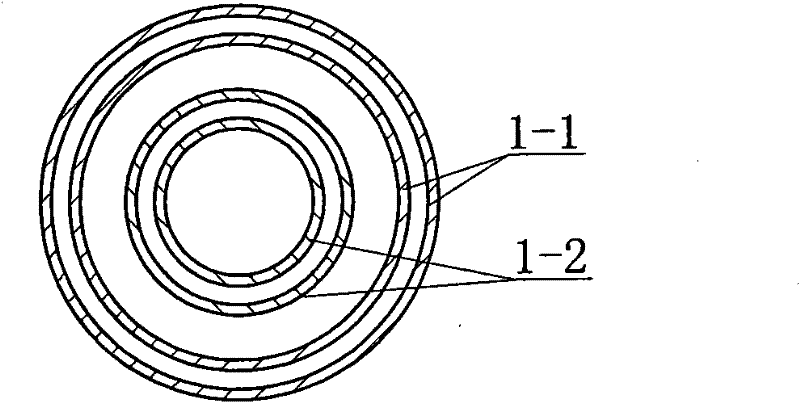

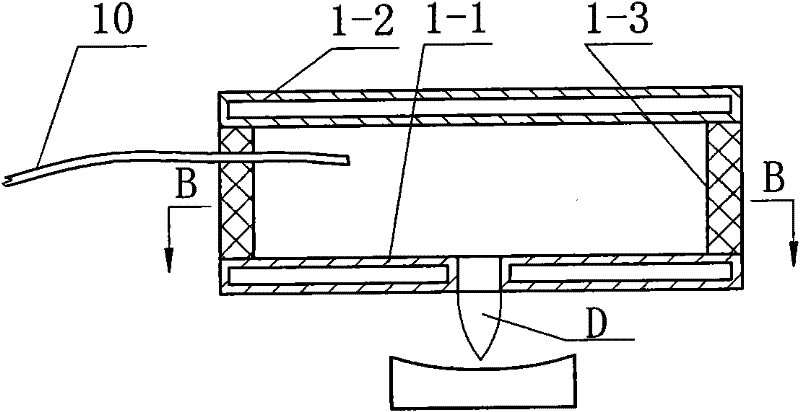

[0031] The plasma generator 1 includes a cathode 1-1 and an anode 1-2 that are parallel or coaxially set, the outer surfaces of the cathode 1-1 and the anode 1-2 are respectively coated with an insulating film, and the cathode 1-1 and the anode 1-2 The internal cavities of the cooling water pump 4 are respectively connected to an outlet of the cooling water pump 4 through pipelines, and the cathode 1-1 and the anode 1-2 are respectively connected to the negative electrode and the positive...

specific Embodiment approach 2

[0064] Specific embodiment two: the difference between this embodiment and embodiment one is that in step three, the flow rate of plasma gas is selected to be 20 liters per minute, and the flow ratio of reaction gas and oxygen to plasma gas is 1:10; step In the fourth step, the power of the radio frequency power supply 2 reaches 800W, and rough molding is performed on the WC or SiC optical molding die. Other components and connections are the same as those in Embodiment 1.

specific Embodiment approach 3

[0065] Specific embodiment three: the difference between this embodiment and embodiment two is that step three is repeated, the flow rate of the selected plasma gas is 20 liters per minute, and the flow ratio of the reaction gas and oxygen to the plasma gas is 1:20; Fourth, make the power of the radio frequency power source 2 reach 500W, and carry out precision molding processing on the WC or SiC optical molding die. Other components and connections are the same as those in Embodiment 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com