Flat heater and plasma processing equipment

A heater, plate technology, applied in metal material coating process, semiconductor/solid-state device manufacturing, gaseous chemical plating, etc., can solve the influence of temperature uniformity, plasma distribution uniformity, heating performance and plate grounding performance. and other problems, to achieve the effect of small uniformity, stable mechanical structure and guaranteed flatness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

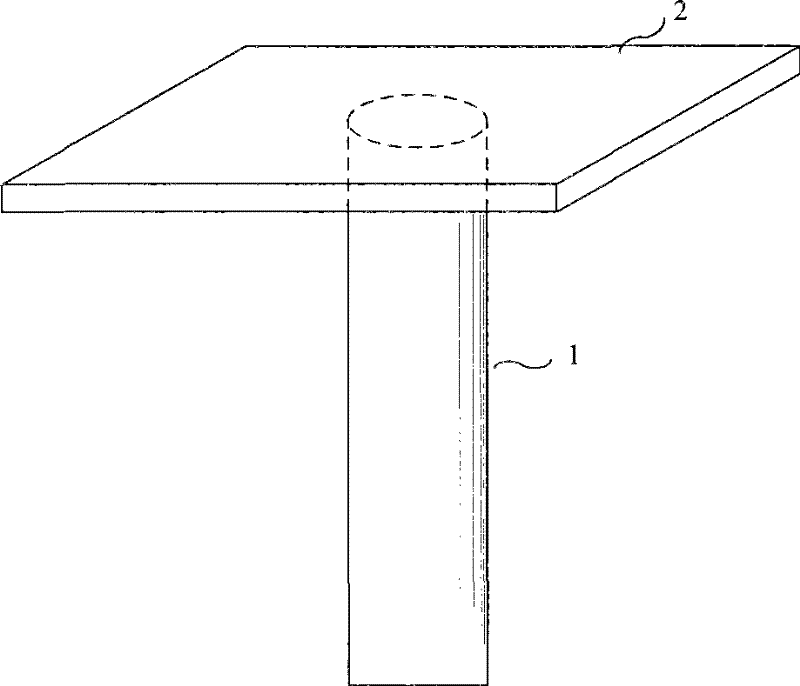

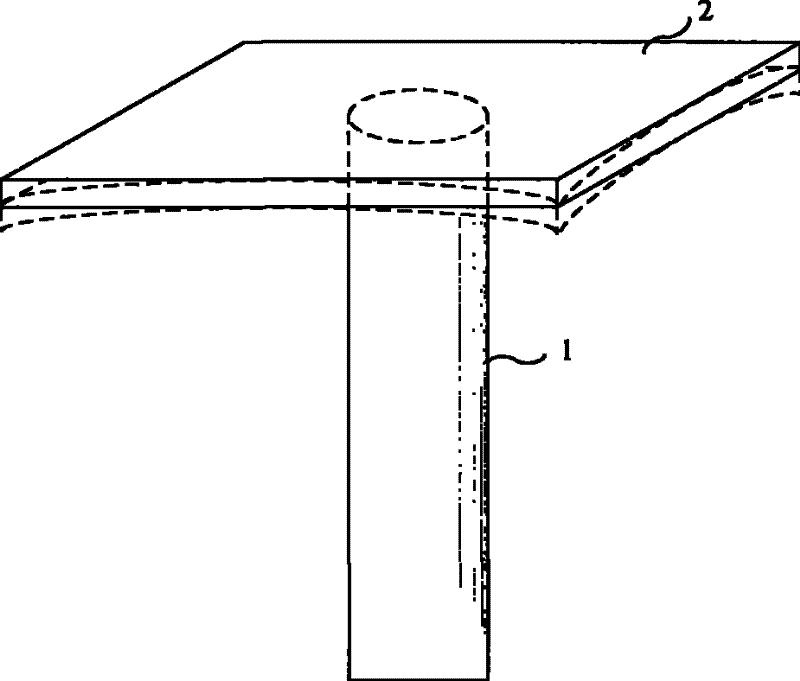

[0033] Specific embodiment one, such as Figure 4 , Figure 5 , Figure 6 Shown:

[0034] The flat panel heater comprises a main support 1 and a heating plate 2, and the heating plate 2 is in the shape of a square plate. The main support 1 is columnar, supported in the middle of the heating plate 2, and supports the heating plate 2 to maintain a level.

[0035] Auxiliary supports 3a, 3b, 3c, 3d are respectively provided between the main support 1 and the four corners of the heating plate 2, which are used to reinforce and assist the main support 1 to ensure the rigidity and stability of the entire structure.

[0036] Connectors 4a, 4b, 4c, 4d are respectively provided between the four corners of the heating plate 2 and the auxiliary supports 3a, 3b, 3c, 3d, for realizing the connection between the two. Meanwhile, the connectors 4a, 4b, 4c, The length of 4d is adjustable or optional, and an appropriate length can be selected according to the degree of thermal deformation of...

specific Embodiment 2

[0042] Specific embodiment two, such as Figure 7 As shown, there are eight auxiliary supports 3, which are respectively supported on the four corners and four sides of the heating plate 2. The structure of the auxiliary support 3 itself is not limited to columns, and other structural forms can be adopted according to the actual application, such as:

specific Embodiment 3

[0043] Specific embodiment three, such as Figure 8 As shown, the auxiliary support is in the form of a support plate 31, and four support plates 31 can be provided to be respectively supported between the four sides of the heating plate 2 and the main support 1;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com