Colorful composite floor board

A composite floor, dazzling technology, applied in decorative arts, crafts for producing decorative surface effects, construction, etc., can solve the problems of loose particles, falling off, high floor production cost, poor bonding force, etc., to achieve the process flow The effect of simplicity, wide application range and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

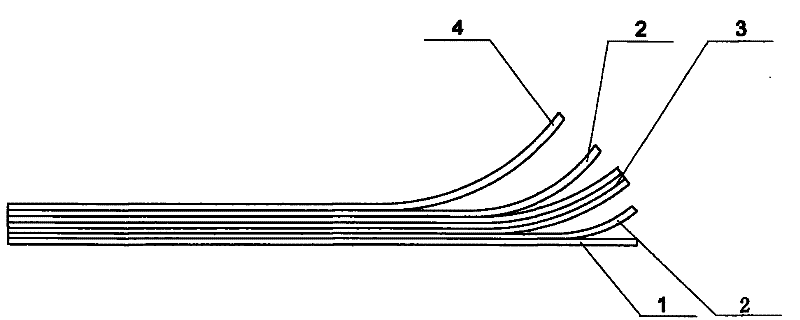

[0012] Example 1: See the attached figure, the colorful composite floor is composed of a bottom layer, a pattern layer and a wear-resistant layer. The bottom layer is a white polyvinyl chloride sheet 1 with a thickness of 0.6mm. The white sheet is formed by calendering 97% (mass percentage, the same below) of PVC and 3% of titanium white pigment. The pattern layer is composed of two printed sheets 2 and a transparent spacer 3 sandwiched therebetween, and the transparent spacer 3 is composed of three layers of PVC transparent sheets with a thickness of 0.5 mm. The wear-resistant layer is a PVC transparent film 4 with a colorless UV paint layer on the outer surface, and the thickness is 0.3mm. Each layer (film) in the above structure is hot-pressed into one body by conventional technology on a general-purpose hot press.

[0013] The printing sheet is coated with pearlescent oil on a 0.07mm thick PVC transparent sheet, and then a specific pattern is printed on the pearlescent oi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com