Semiconductor wafer film thickness detecting device on basis of infrared optical interference method

A technology of infrared optics and detection devices, which is applied in the direction of optical devices, measuring devices, semiconductor/solid-state device testing/measurement, etc., can solve the problems of not being easy to detect concentric circles, wafer detection, troublesome layout, etc., to achieve signal Processing and automatic detection, improving product quality, and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

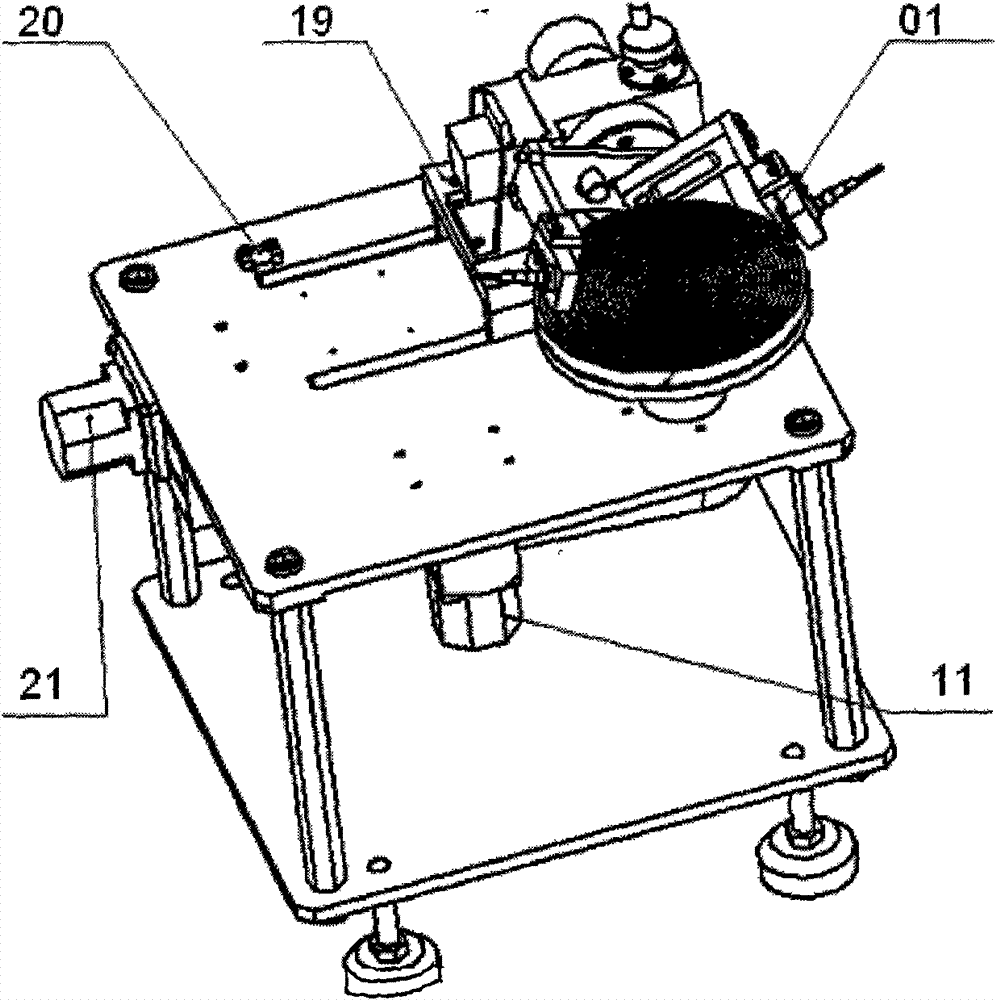

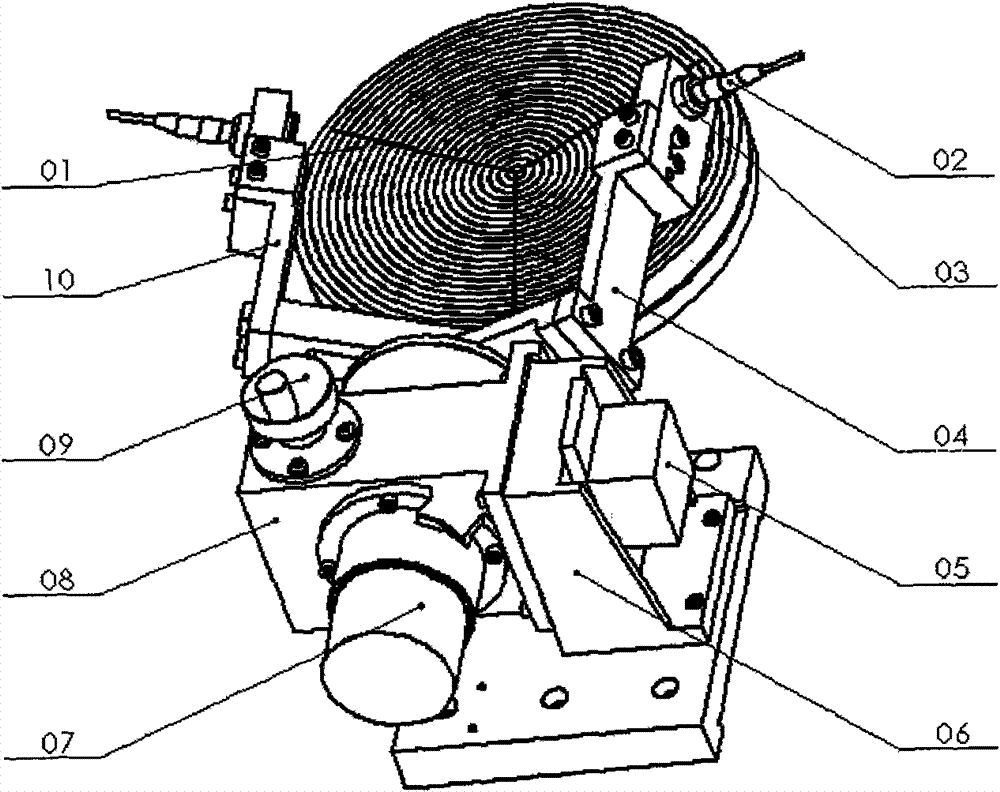

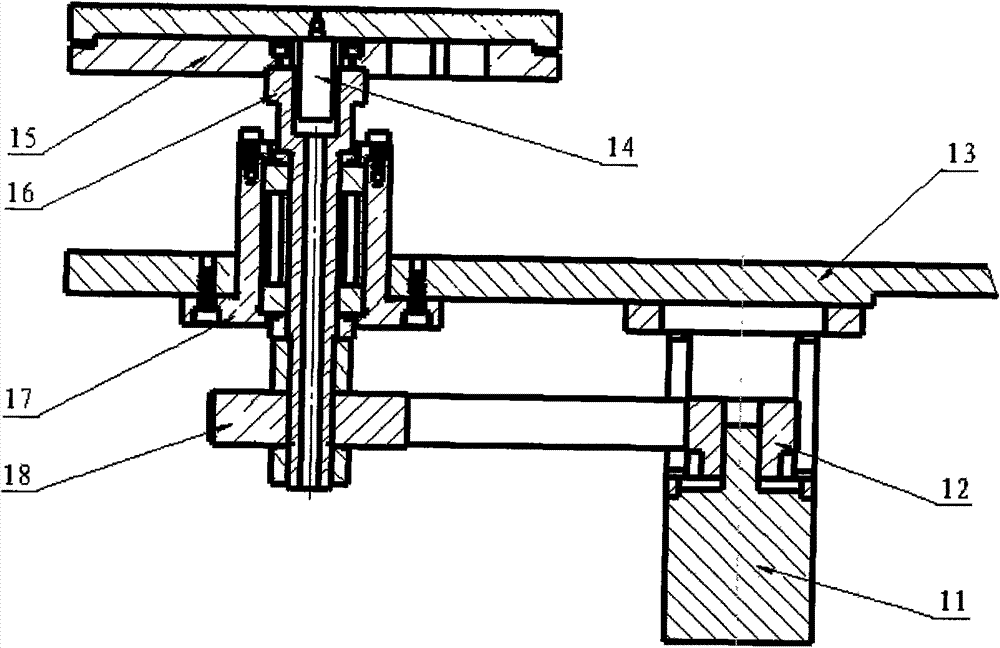

[0031] The structure of the device of the present invention is mainly composed of three parts: the carrying and rotating mechanism of the wafer, the adjustment and moving mechanism of the laser, and the vacuum adsorption gas path of the wafer. The structure of the device is as follows: figure 1 shown.

[0032] Based on the principle of thin film interference of light, such as Figure 10 . The light intensity after interference is

[0033] E = E 1 + E 2 + 2 E 1 E 2 cos ( 4 n 2 π d cos θ λ )

[0034] The film thickness d can be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com