Manufacturing method and apparatus for plastic membranes

A manufacturing method and a manufacturing device technology, which are applied in the field of plastic film manufacturing and devices, can solve problems such as uneven stretching at the end of film products, unstable width changes, and sparks, so as to avoid spark discharge failures, excellent quality, Effect of Stable Discharge Characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

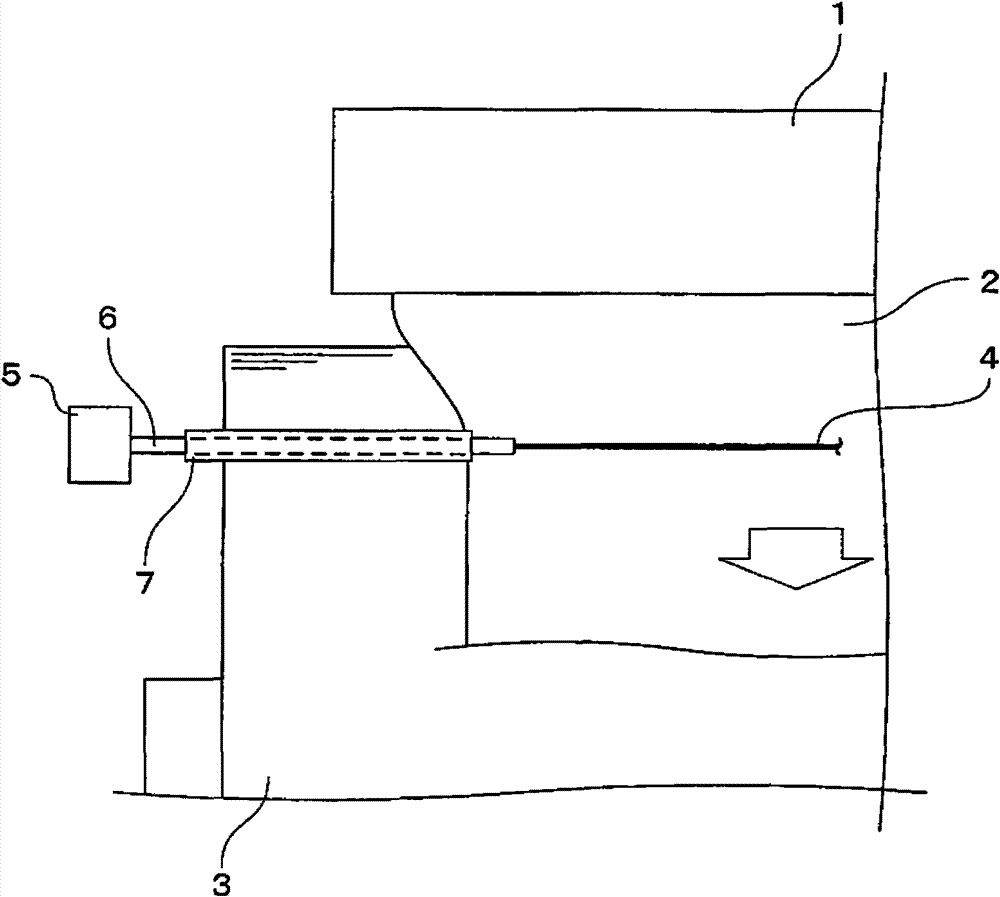

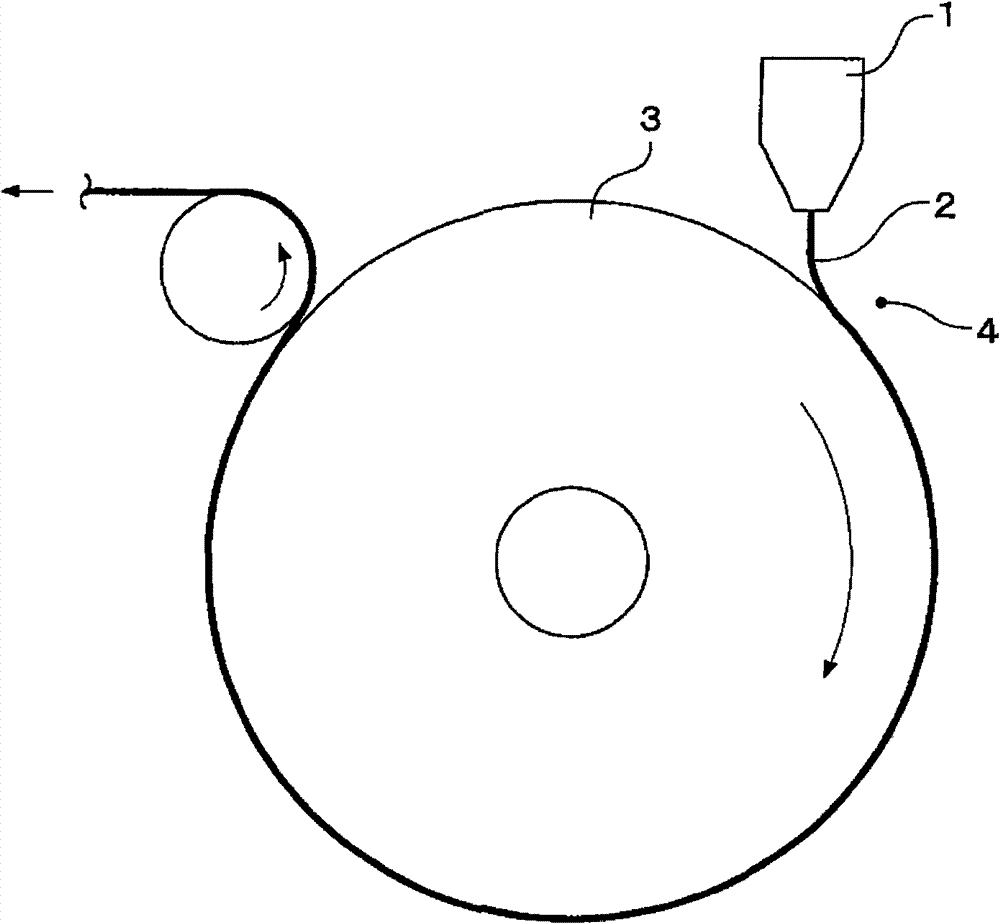

[0051] Molten polyethylene terephthalate is extruded in a film form from a T-shaped die head, and a cooling roll with a surface temperature of 20°C is rotated at a speed of 60m / min, and is cooled and formed into a film with a width of 1100mm and a thickness of 195μm by electrostatic bonding. Unoriented film.

[0052] At this time, a tungsten wire with a diameter of 0.1 mm was erected at a distance of 1450 mm between the supports near the junction of the film-like melt and the cooling roll, and a tungsten wire of 10 mm inward from the end of the film-like melt in the width direction from the support to the melt was placed. Position, set the secondary electrode made of stainless steel tube on the electrode cover. The magnification of the cross-sectional area by the sub-electrode is 6.2 times, and the conduction resistance is about 1 / 3. Also cover the two ends of the electrode with ceramic sleeves for insulation, and make the front end of the sleeve enter a position about 3 mm i...

Embodiment 2

[0059] Under the same conditions as in Example 1 except for the following, it was cooled and formed into a polyethylene terephthalate film.

[0060] That is, instead of the lead wire of Example 1, a stainless steel blade with a width of 3 mm and a thickness of 0.02 mm was erected at a distance between the supports of 1450 mm in the vicinity of the junction of the film-like melt and the cooling roll, and the film was compared in the width direction from the support to the melt. As far as the end of the molten body is 10 mm inside, the sub-electrodes are placed between the U-shaped fittings. The magnification ratio of the cross-sectional area by the sub-electrode is 6.2 times, and the conduction resistance is about 1 / 4. Both ends of the electrode were also covered with a ceramic sleeve so that the front end of the sleeve entered a position about 3 mm inward from the end of the film-like melt in the width direction of the melt. A heating current was flowed into the electrode, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com