Preparation method of nano particle modified insulating oil based on iron occurrence form

A nanoparticle and insulating oil technology, applied in insulators, petroleum industry, transformer/inductor components, etc., can solve problems such as aluminum pollution, achieve low cost, simple operation, and improve insulation performance and thermal conductivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0019] The present invention proposes a method for preparing a nanoparticle-modified insulating oil based on the form of iron. The insulating oil is applied to an oil-immersed power transformer. Specifically, the method includes the following steps:

[0020] Step 1: Prepare 40 mL of oleic acid ethanol solution with a mass fraction of 40% to 80%, stir evenly for later use; prepare 10 mL of hexamethylenetetramine ethanol solution with a mass fraction of 5% to 10%, stir evenly for later use, wherein Oleic acid ethanol solution is prepared by dissolving oleic acid in ethanol; hexamethylenetetramine ethanol solution is prepared by dissolving hexamethylenetetramine in ethanol;

[0021] Step 2: Mix and stir the oleic acid ethanol solution prepared in step 1 and the hexamethylenetetramine ethanol solution evenly, and leave to age for 2h to 4h to obtain the modifier;

[0022] Step 3: Mix 1 L of insulating oil with the modifier obtained in Step 2, add 5 mL to 10 mL of hexadecene, and co...

Embodiment 1

[0025] 1 involved in embodiment 1, embodiment 2 and embodiment 3 # insulating oil, 2 # insulating oil, 3 # Insulating oil samples were taken from three oil-immersed power transformers.

[0026] Example 1

[0027] In this embodiment, the preparation method of nanoparticle-modified insulating oil based on the iron occurrence form includes the following steps:

[0028] Step 1: Prepare 40 mL of oleic acid ethanol solution with a mass fraction of 40%, stir evenly for use; prepare 10 mL of hexamethylenetetramine ethanol solution with a mass fraction of 5%, stir evenly for use;

[0029] Step 2: Mix and stir the prepared oleic acid ethanol solution and hexamethylenetetramine ethanol solution evenly, and leave to age for 2 hours to obtain a modifier;

[0030] Step 3: Take 1 # Mix 1L of insulating oil with the modifier obtained in step 2 evenly, add 5mL of hexadecene, and continue to react for 2 hours under the condition of a constant temperature water bath of 60°C to 80°C at a sti...

Embodiment 2

[0033] In this embodiment, the preparation method of nanoparticle-modified insulating oil based on the iron occurrence form includes the following steps:

[0034] Step 1: Prepare 40 mL of oleic acid ethanol solution with a mass fraction of 60%, stir evenly for use; prepare 10 mL of hexamethylenetetramine ethanol solution with a mass fraction of 7%, stir evenly for use;

[0035] Step 2: Mix and stir the prepared oleic acid ethanol solution and hexamethylenetetramine ethanol solution evenly, and leave to age for 2 hours to obtain a modifier;

[0036] Step 3: Take 2 # Mix 1L of insulating oil with the modifier obtained in step 2 evenly, add 7mL of hexadecene, and continue the reaction for 2 hours under the condition of a constant temperature water bath of 60°C to 80°C at a stirring speed of 200r / min.

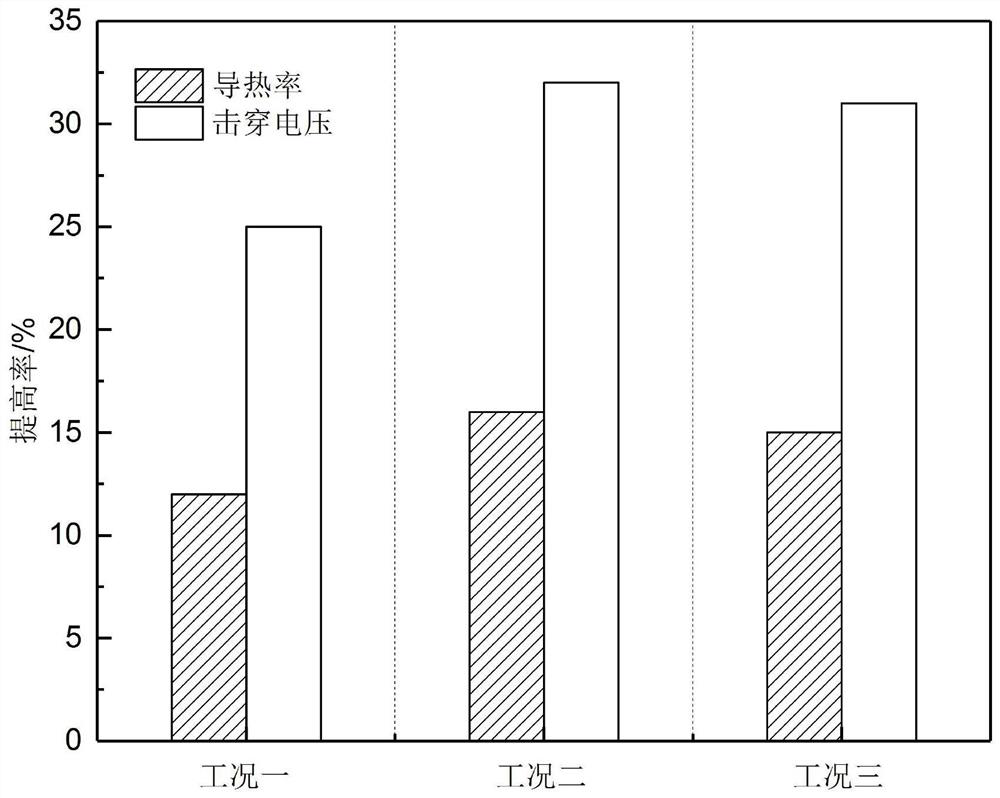

[0037] Depend on figure 1 It can be seen (working condition 2), this embodiment significantly improves the thermal conductivity and breakdown voltage of the insulating oil, and i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com