Sol-type flame retardant, preparation method and application thereof

A technology of flame retardant and sol, which is applied in the field of sol-type flame retardant and its preparation and application, which can solve the problems of easy yellowing of the fabric surface and hard hand feeling of the fabric, so as to improve the hand feel, enhance the durability, and improve the washing fastness. degree of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

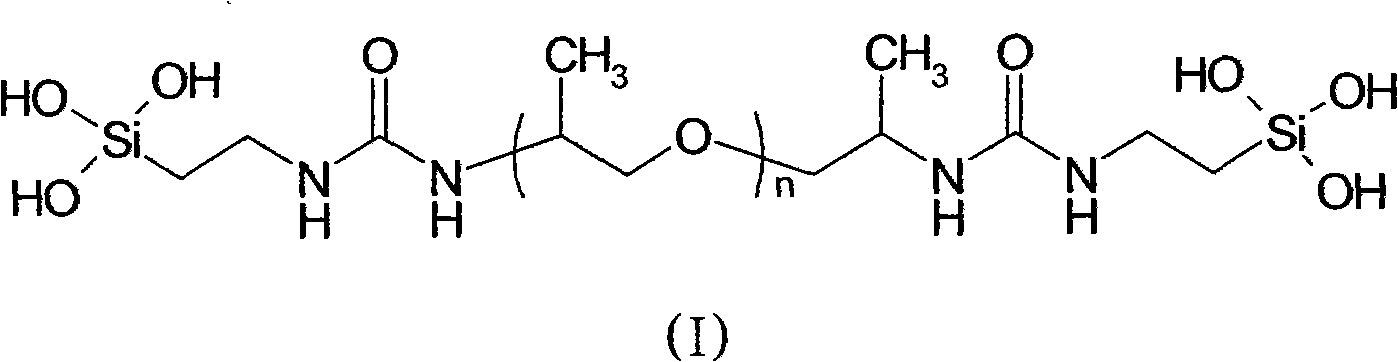

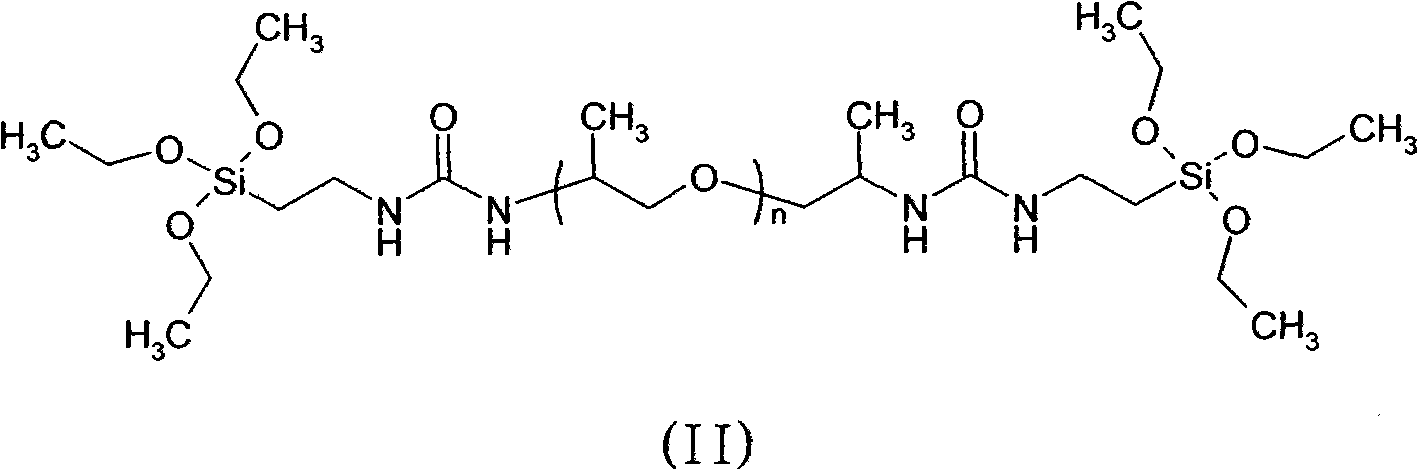

[0045] Example 1: The preparation of a precursor formed by reacting polyetheramine (molecular weight: 2000) with IPTES.

[0046] At room temperature, weigh 50 grams of polyetheramine into a three-necked flask, and add 11.15 grams of IPTES dropwise at a certain molar ratio (polyetheramine:IPTES=1.02:2), and heat up to 80 °C, the reaction was continued for 1 hour, and the reaction temperature was lowered to room temperature to obtain a precursor.

Embodiment 2

[0047] Example 2: Preparation of polyetheramine modified γ-isocyanate propyltriethoxysilane (IPTES) hydrolyzate.

[0048] Add 69 grams of the polyetheramine modified γ-isocyanate propyltriethoxysilane (IPTES) precursor in the three-necked flask in Example 1, and slowly add a total of 112 grams of ethanol and 28 grams of water under constant stirring at room temperature. Mix the solution, react for 2 hours, and stand still for 10 hours to obtain a stable polyetheramine-modified γ-isocyanate propyltriethoxysilane (IPTES) hydrolyzate.

Embodiment 3

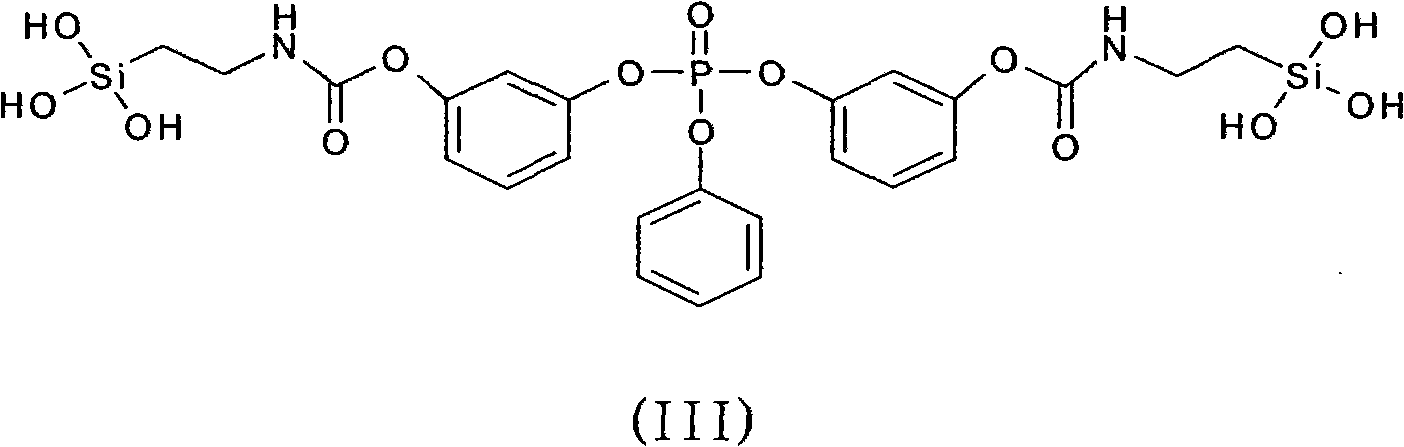

[0049] Embodiment 3: The preparation of the precursor generated by the reaction of phosphate ester and IPTES.

[0050] At room temperature, weigh 89.5 grams of phosphoric acid ester and place it in a three-necked flask, and add 111.5 grams of IPTES dropwise in a certain molar ratio (phosphoric acid ester: IPTES=1.02:2) to the three-necked flask, and heat up to 80°C. The reaction was continued for 1 hour, and the reaction temperature was lowered to room temperature to obtain a precursor.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Areal density | aaaaa | aaaaa |

| Areal density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com