Preparation method of molybdenum and molybdenum alloy surface anti-oxidation coat

An anti-oxidation and molybdenum alloy technology is applied in the field of preparation of anti-oxidation coatings on the surface of molybdenum and molybdenum alloys, which can solve the problems of high equipment requirements, complex process and high cost, achieves wide source of raw materials, simple preparation method, and prevents oxidation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

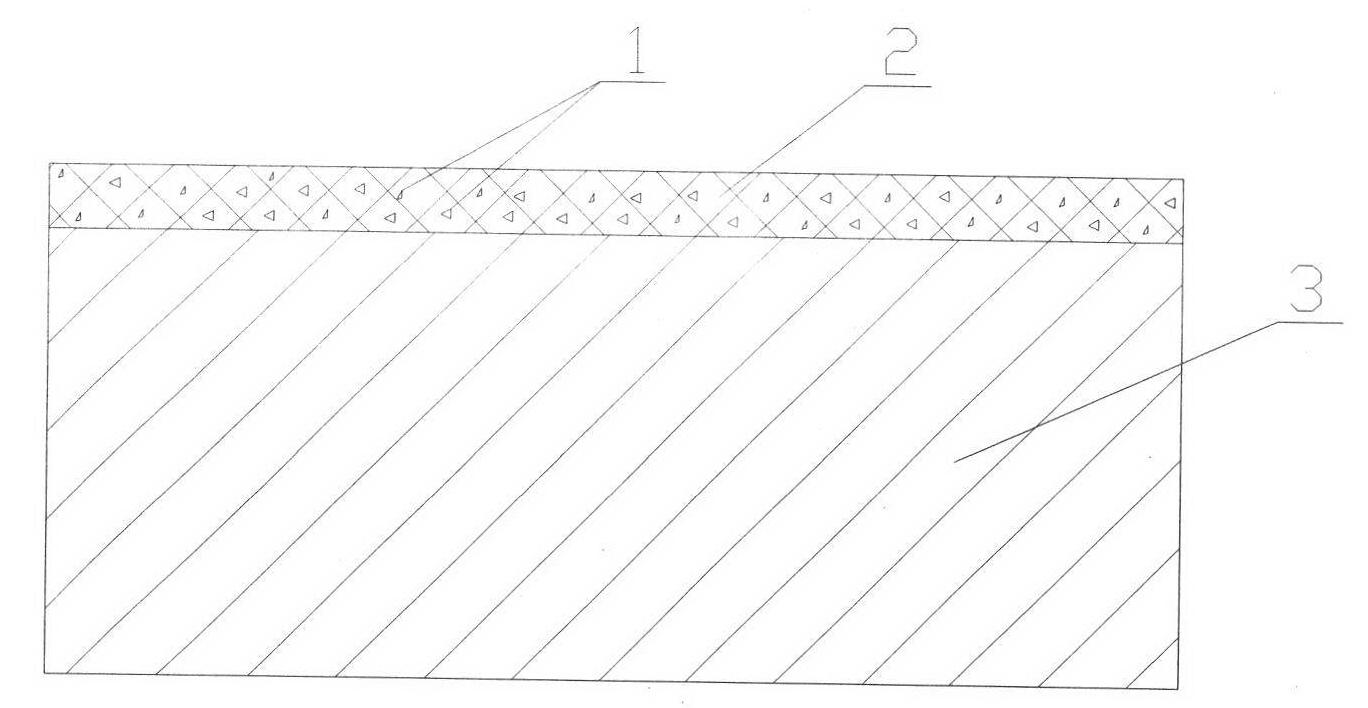

Image

Examples

Embodiment 1

[0025] (1) Preparation of matrix

[0026] Wash the molybdenum rod with weak alkali, weak acid, water and dry to remove the dirt, grease, oxide layer and impurities on the surface of the substrate. The binding force of the matrix;

[0027] (2) Preparation and coating of paint

[0028] (a) barium silicate glass frit (mass percentage is SiO 2 : 37%; BaO: 45%; B 2 o 3 : 6%; ZnO: 5%; CaO: 5%; Al 2 o 3 : 2%;) mix evenly, and then smelt at 1450°C for 2h to 4h, as long as it is melted, quickly water-cool the high-temperature glass melt, and after ball milling for 72h, pass through a 200-mesh sieve to form the base glaze;

[0029] (b) with ZrO 2 It is a refractory filler in molybdenum glaze, and the ratio of molybdenum glaze is base glaze: ZrO 2 : Clay is 14:2:1.

[0030] (c) Mix terpineol and ethyl cellulose in a mass ratio of 100:1.5 in a water bath (50-70°C, 8-10h) to obtain varnish;

[0031] (d) Stir the molybdenum glaze and varnish in a magnetic stirrer in a ratio of 2:1...

Embodiment 2

[0036] (1) Preparation of matrix

[0037] Same as embodiment 1.

[0038] (2) Preparation and coating of paint

[0039] (a) Same as Example 1.

[0040] (b) with ZrO 2 It is a refractory filler in molybdenum glaze, and the ratio of molybdenum glaze is base glaze: ZrO 2 : Clay is 14:3:1.

[0041] (c), (d) and (e) are the same as in Example 1. The test method is the same as in Example 1.

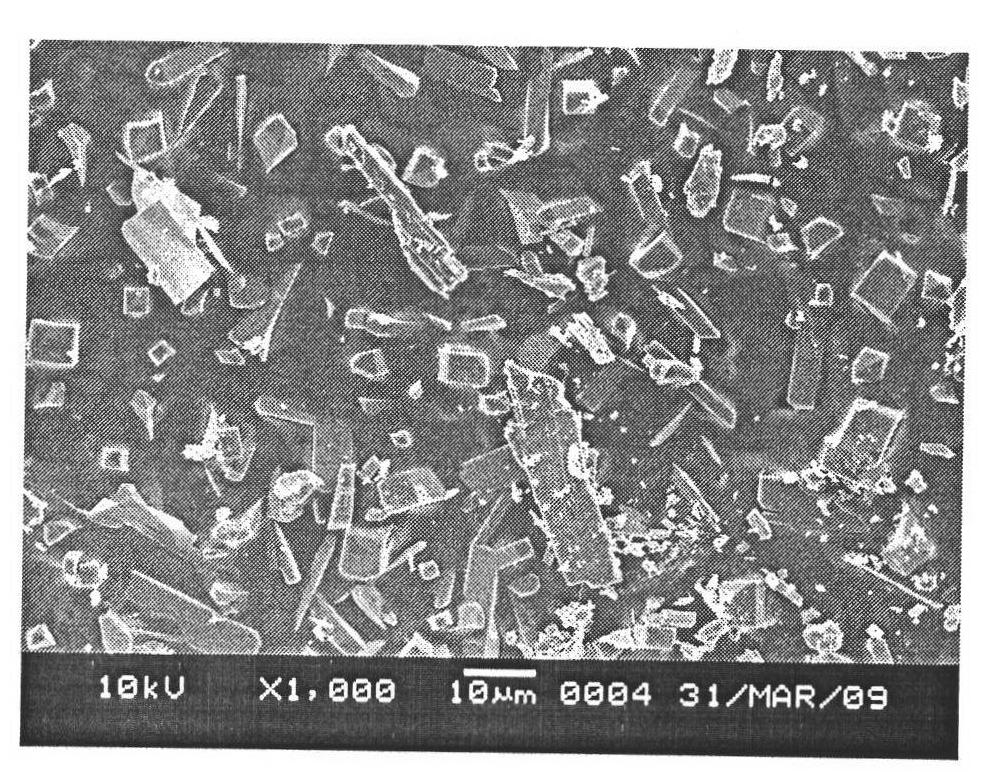

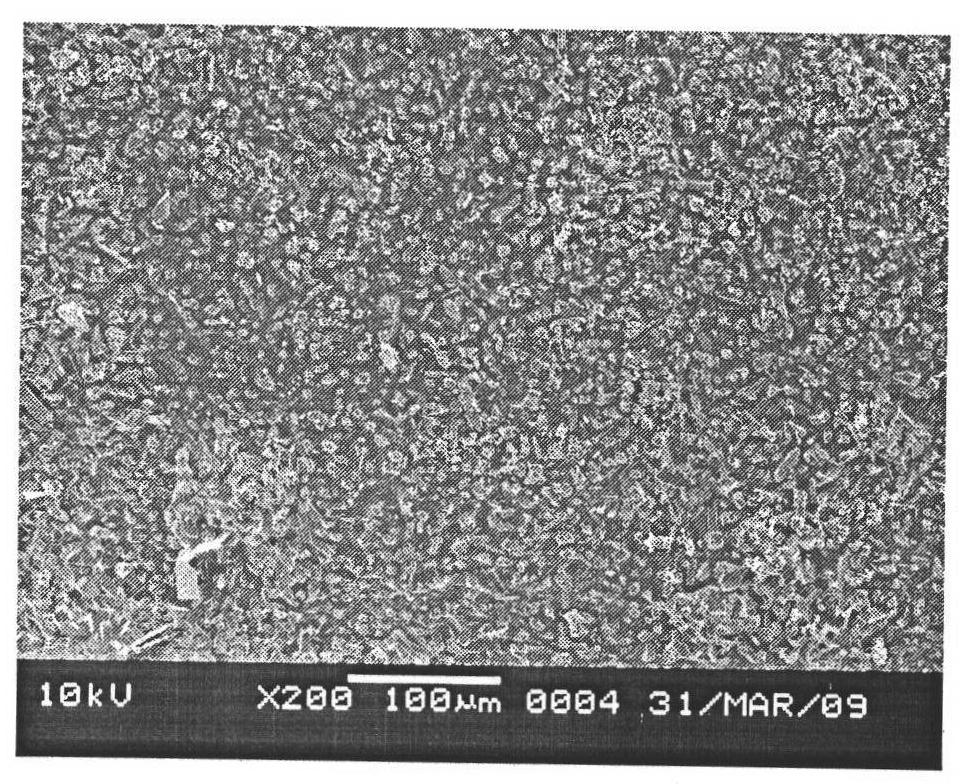

[0042] The weight loss of the bare molybdenum substrate reaches 180mg / cm at 1000°C in 30 minutes 2 , while the weight loss of the substrate protected by the coating in this test is only 16.34mg / cm 2 . After the coated molybdenum substrate was pre-fired at 1000°C for 2 hours, the coating on the surface was peeled off and the energy spectrum (EDS) analysis was performed on the substrate. The oxygen content was only about 6.3% of the oxygen content without coating, and the anti-oxidation effect was remarkable. .

Embodiment 3

[0044] (1) Preparation of matrix

[0045] Same as embodiment 1.

[0046] (2) Preparation and coating of paint

[0047] (a) Same as Example 1.

[0048] (b) with ZrO 2 It is a refractory filler in molybdenum glaze, and the ratio of molybdenum glaze is base glaze: ZrO 2 : Clay is 14:6:1.

[0049] (c), (d) and (e) are the same as in Example 1. The test method is the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com