Equipment for testing vibration performance of air spring and method of using the same for testing

A technology of air spring and test method, which is applied in the direction of using repetitive force/pulse force to test material strength, force/torque/work measuring instrument calibration/test, measuring device, etc., can solve the problem of non-calibration of test equipment and unchanged instrument and other problems, to achieve the effect of preventing eccentric loading, convenient and flexible selection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] Below in conjunction with specific embodiment the present invention will be further described

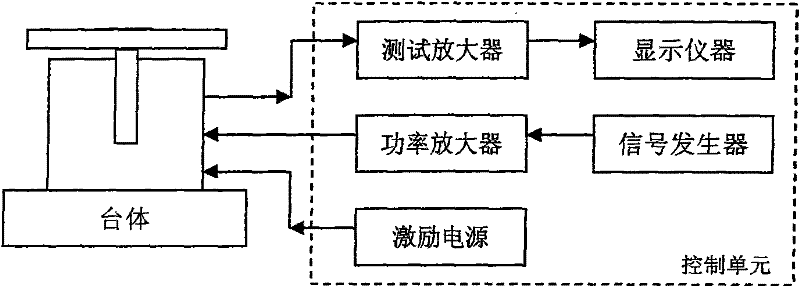

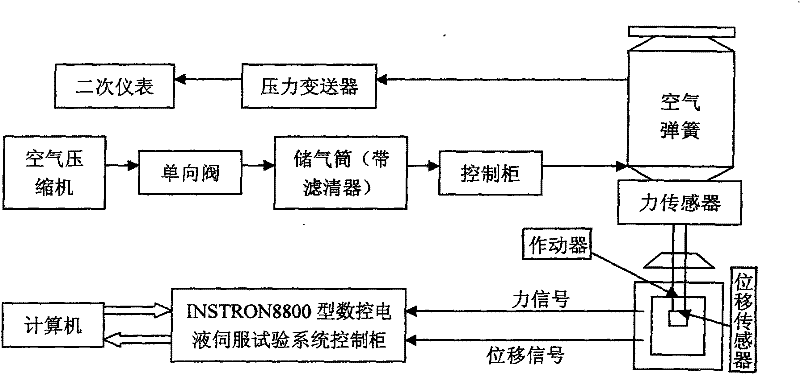

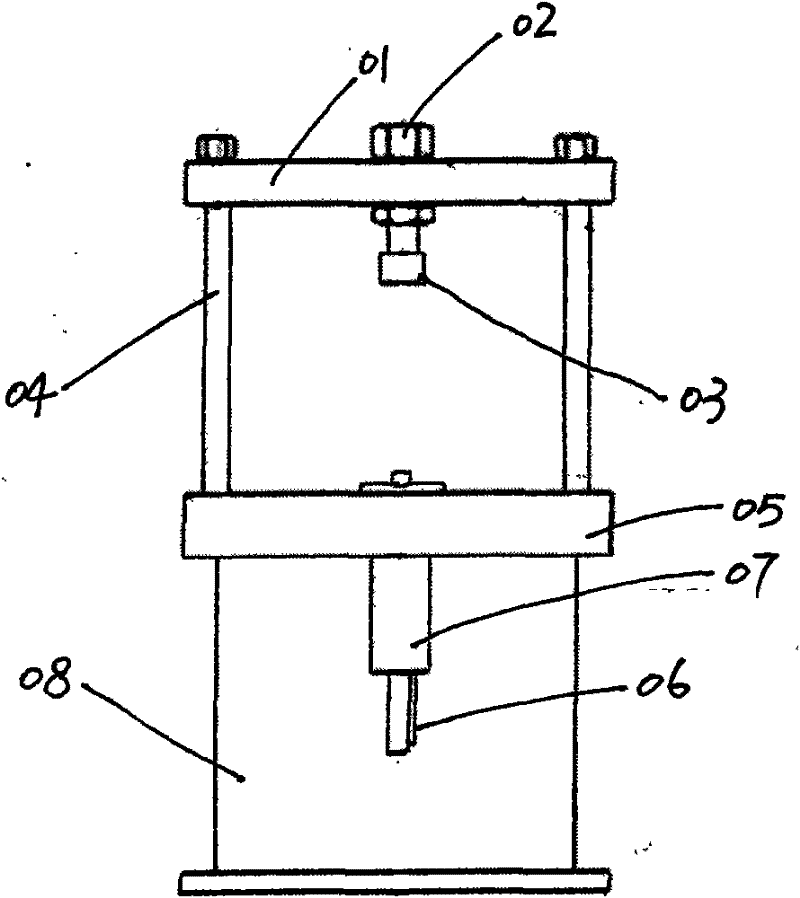

[0055] Such as Figure 5 As shown, the equipment for testing the vibration characteristics of an air spring includes a vibrator and a mass block 7 rigidly fixedly connected with the vibrator, a force sensor 7 is arranged between the vibrator and the mass block 7, and the mass block 7 is provided with a displacement sensor; the signal generator and the power amplifier are connected to the vibrator in turn through electrical signals; the force sensor 5 and the displacement sensor transmit their signals to the charge amplifier for signal amplification, and then store them in the computer; The vibrator is an electric vibrator 6, and the rigidly fixedly connected mass 7 and the electric vibrator 6 are suspended in the air; the displacement sensor is a laser displacement sensor 3; the mass 7 is also provided with Acceleration sensor 4 and displacement induction plate 8; Described ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com