Automatic separating equipment for regular objects

An automatic sorting and object technology, applied in sorting and other directions, can solve the problems of low sorting efficiency and broken machines, and achieve the effect of improving sorting efficiency, avoiding blocking equipment, and keeping itself tidy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

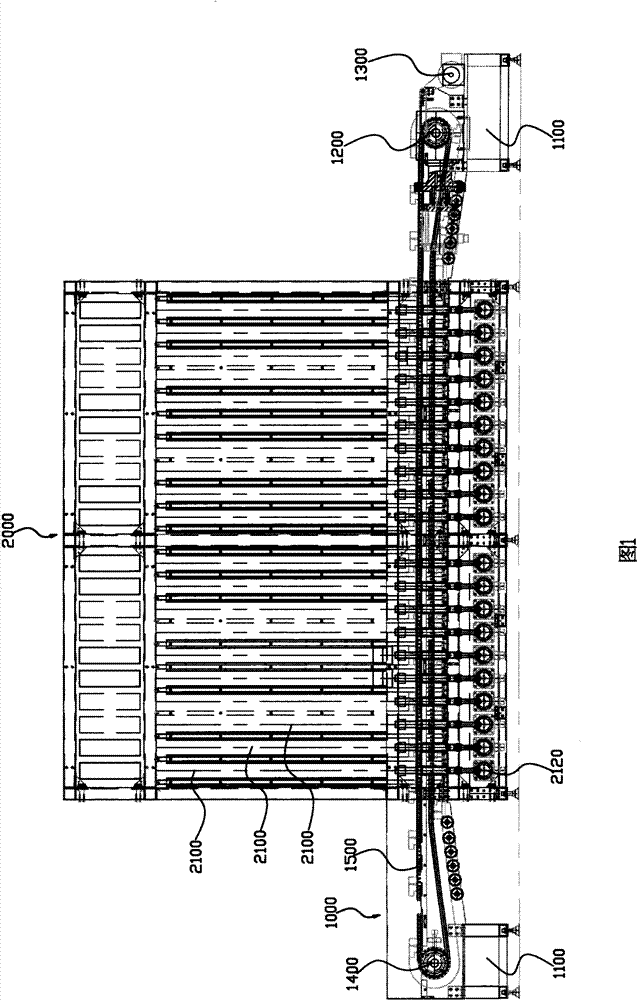

[0025] An automatic sorting device for regular objects, please refer to FIG. 1 , a left and right horizontal conveying mechanism 1000 , a sorting assembly 2000 and a servo control unit 3000 .

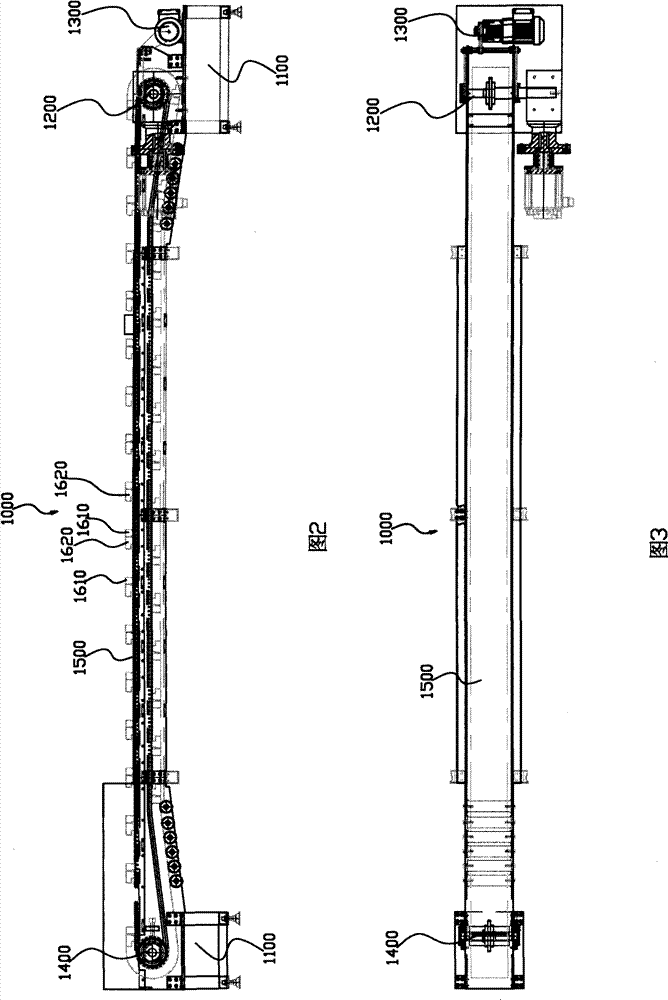

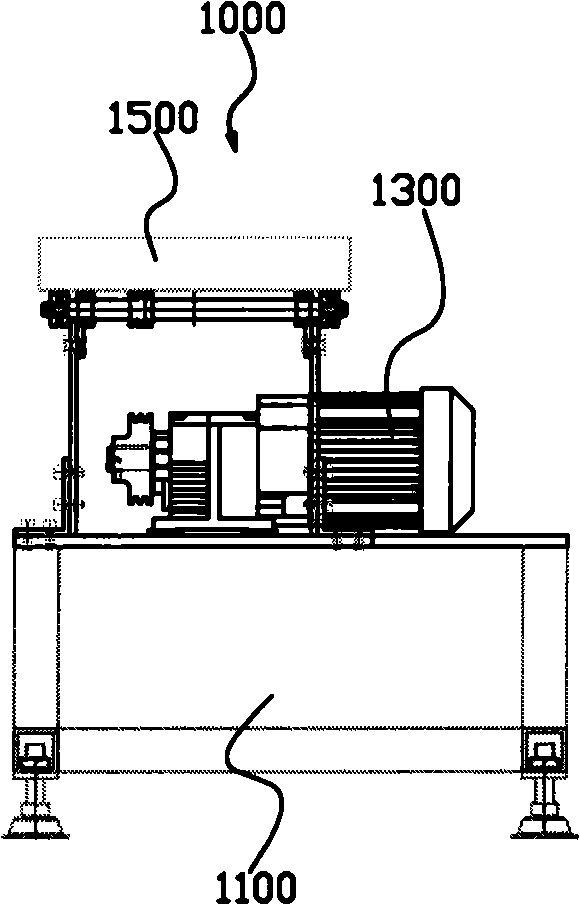

[0026] Please refer to Figure 2, Figure 3 and Figure 4 , the left and right lateral conveying mechanism 1000, which includes: two bases 1100 arranged side by side at intervals, a motor 1200 arranged on the base 1100, a motor 1200 that can be rotated and installed on the base 1100, and is connected to the motor 1200 The drive shaft 1300 of the power output shaft, a driven shaft 1400 that can rotate and be arranged on another base 2200, a chain 1500 connecting the drive shaft 1300 and the driven shaft 1400, through the cooperation of the drive shaft 1300 and the driven shaft 1400 , to drive the chain 1500 to move horizontally. The transmission connection between the motor 1200 and the drive shaft 1300 can be driven by a secondary pulley. Since the driving shaft 1300 and the driven shaft...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com