A pipeline type tank juice catcher

A juice catcher and pipe-type technology, which is applied in the fields of sucrose production, sugar production, sugar solution boiling/evaporation, etc., can solve the problem of increasing boiler water energy and softening costs, increasing the burden and cost of sewage treatment in sugar factories, fog The problem of foam entrainment loss and other problems can be avoided, and the effect of saving preheating energy consumption and softening cost, improving recycling rate and reducing sugar content can be achieved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

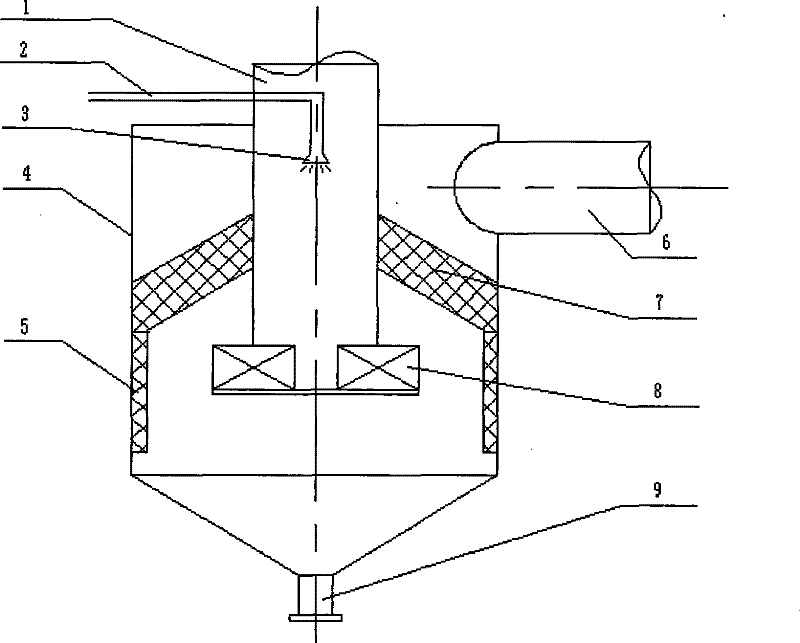

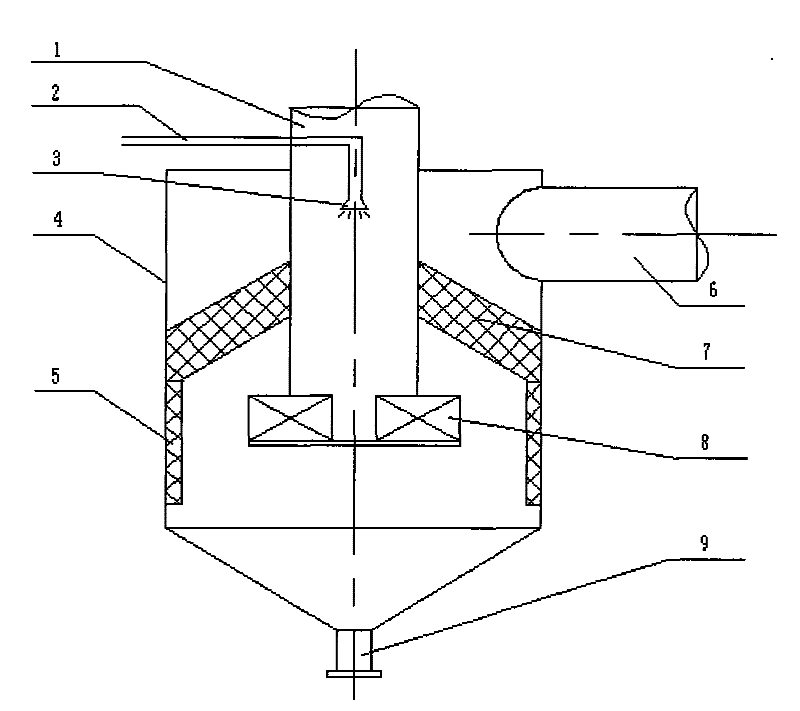

[0015] figure 1 . is a schematic structural view of the pipeline type juice catcher outside the tank of the present invention.

[0016] In the figure: juice vapor inlet pipe 1, hot water pipe 2, nozzle 3, circular outer cylinder 4, deflector 5; juice vapor outlet pipe 6, packing layer 7, cyclone 8, water outlet pipe 9.

[0017] Such as figure 1 As shown, the juice catcher circular outer cylinder 4 of the present invention is sprayed with hot water at the same temperature as the juice vapor through the hot water pipe 2 from the nozzle 3 to the juice vapor entering from the juice inlet pipe 1, and the surface of the water droplets absorbs sugar After the particles are separated by the cyclone 8, the coarsened sugar solution in the juice vapor quickly breaks away from the juice vapor flow under the synergistic effects of baffle, inertia, and centrifuga...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com