Textile spraying decoration equipment

A spraying and equipment technology, which is applied in the direction of processing textile material equipment configuration, textile and papermaking, textile processing machine accessories, etc., can solve the problems of difficult control, pattern deformation, and positioning errors, etc. Accurate spray effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

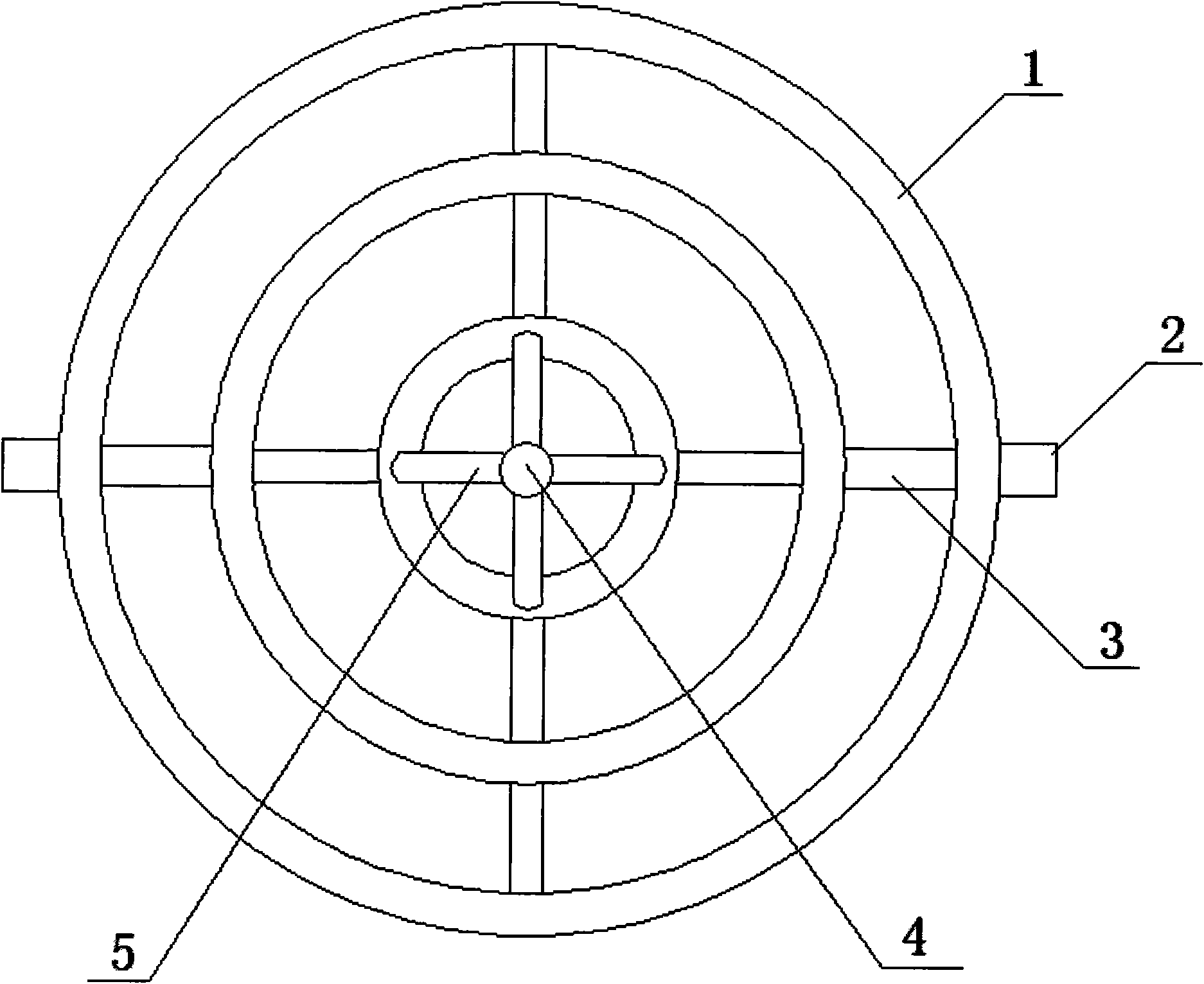

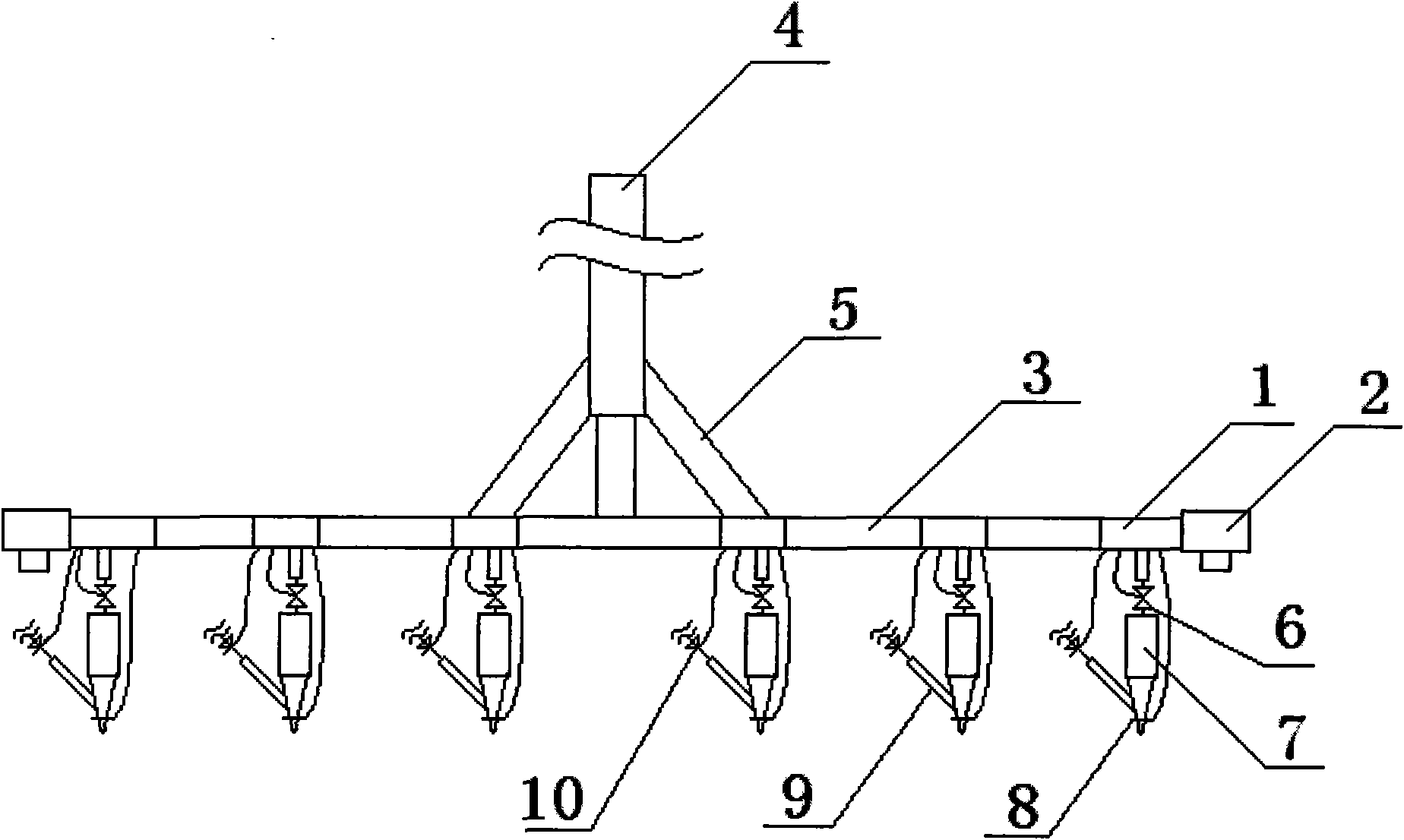

[0008] As shown in the figure, a fabric spraying equipment of the present invention includes a bracket 1, a position sensor 2, a connecting beam 3, a cantilever 4, a connecting rod 5, an air pipe solenoid valve 6, a spray gun 7, an electronic adjustment switch 8, a color liquid Pipe 9, color liquid pipe electromagnetic valve 10. The brackets 1 are circular, three are shown in the figure, but not limited thereto. The brackets 1 are connected to each other by connecting beams 3 to form a whole. A connecting rod 5 is installed on the innermost bracket, and the bracket 1 is fixed with the cantilever 4 through the connecting rod 5 . A plurality of spray guns 7 are installed on the support 1, the spray gun 7 upper ends are connected to the air source through the air pipe, and the air pipe electromagnetic valve 6 is arranged on the air pipe; The color liquid pipe solenoid valve 10 is provided on the liquid pipe 9, and the electronic adjustment switch 8 is provided on the nozzle. P...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap