Heating system for lining of tunnel opening section

A heating system and tunnel technology, applied in tunnel linings, tunnels, shaft linings, etc., can solve the problems of high maintenance and management costs, high energy consumption, air pollution of fuel boilers, etc., to save later operation and maintenance costs, no CO2 emissions , the effect of saving construction investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

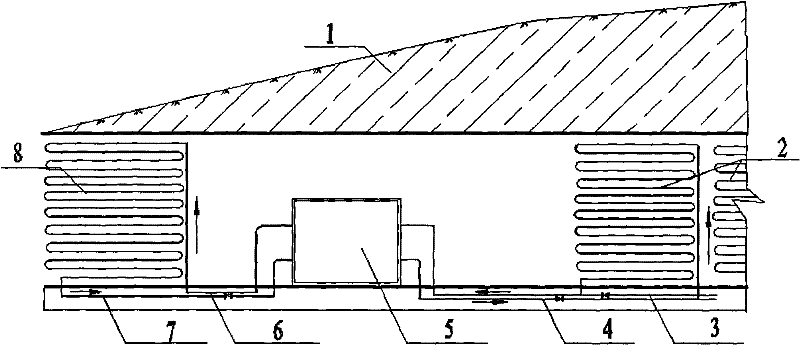

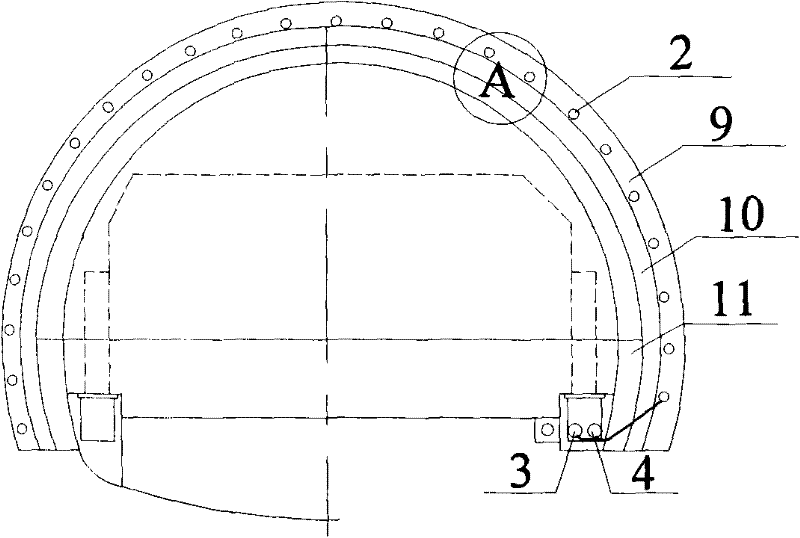

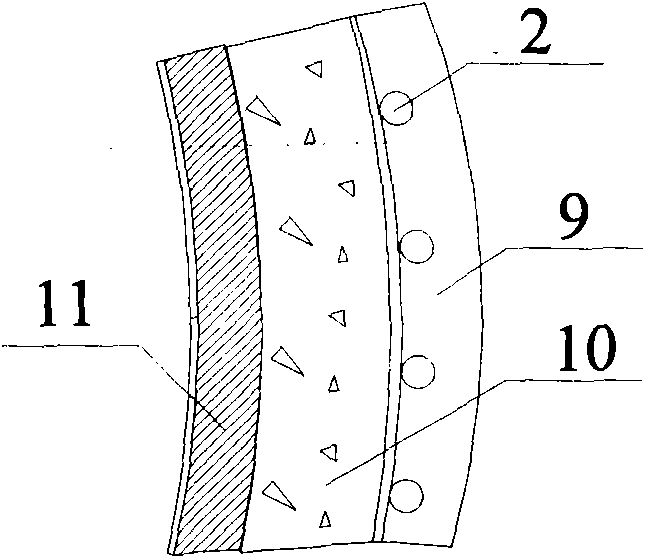

[0027] see Figure 1 to Figure 5 , The lining heating system of the tunnel entrance section includes three parts: front-end collection (heating pipeline), ground source heat pump 5, and end heating (heating pipeline). The front-end collection part is a certain distance away from the tunnel entrance to provide the ground temperature required by the heating system; the end heating part is located at the tunnel entrance and is heated by heat conduction and radiation. The ground source heat pump 5 acts as a transfer station between the front end and the end, responsible for raising the heat collected by the front end and transferring it to the back end. All parts are connected by water inlet and outlet pipes. The front-end collection includes multiple sets of heat exchange tubes 2, and the first and last ends of each set of heat exchange tubes 2 are respectively connected to the first water outlet main pipe 3 and the first water inlet main pipe 4 to form multiple circulation loop...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com