Frequency conversion generator set

A technology for generator sets and generators, applied in electric components, machines/engines, electrical components, etc., can solve the problems of unbalanced structure ratio of generator sets, narrowing of silicon steel sheet extremely wide bandwidth, and increased cost of engines, and the improvement process is simple and convenient. , increase the volume, improve the effect of cost saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

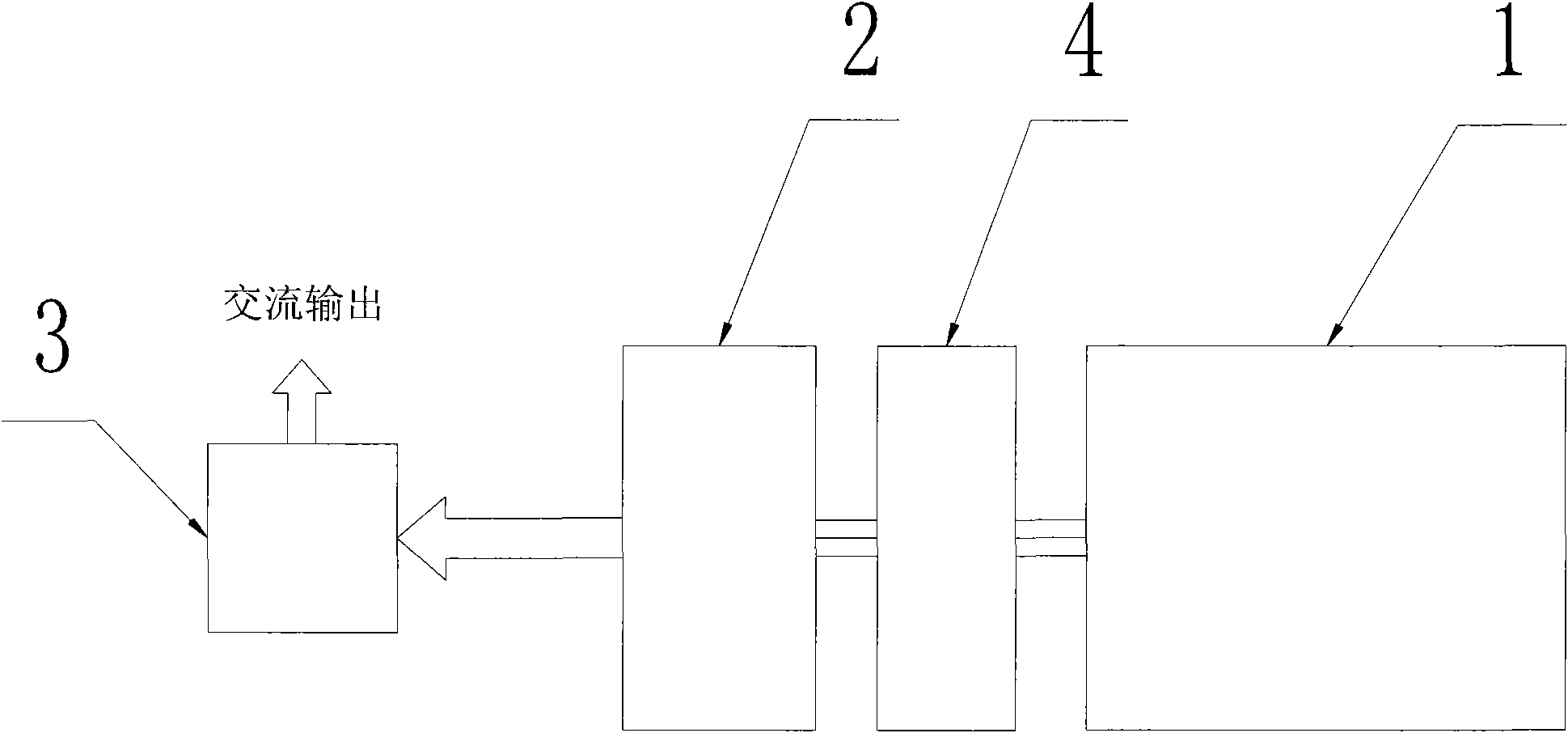

[0022] Example: figure 1 Shown is a specific embodiment of the frequency conversion generating set of the present invention, which includes a multi-pole generator 2, an engine 1 whose output end is connected to the input end of the multi-pole generator 2, and an engine 1 whose input end is connected to the output end of the multi-pole generator 2 AA type frequency conversion converter 3; a speed increaser 4 is installed between the output end of the engine 1 and the input end of the multi-pole generator 2.

[0023] When this embodiment is working, the engine 1 drives the multi-pole generator 2 to run by increasing the speed through the speed increaser 4, so that the frequency of the AC voltage output on the stator of the multi-pole generator 2 is further increased, and the AC voltage is further converted by AA type frequency conversion The thyristor rectifier circuit in the device 3 converts it into the required sinusoidal alternating current output, and its waveform distortio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com