Geometric measurement method of Poisson's ratio and Young's elastic modulus of thin film material

A Young's modulus of elasticity and thin-film material technology, which is applied in the direction of testing the strength of materials by applying a stable bending force, can solve problems such as difficult measurement work, difficulty in proving whether the results are correct, and difficult analysis of thin-film structures.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

[0031] The geometric measurement method of film material Poisson's ratio and Young's modulus of elasticity comprises the following steps:

[0032] (1) Mechanical model

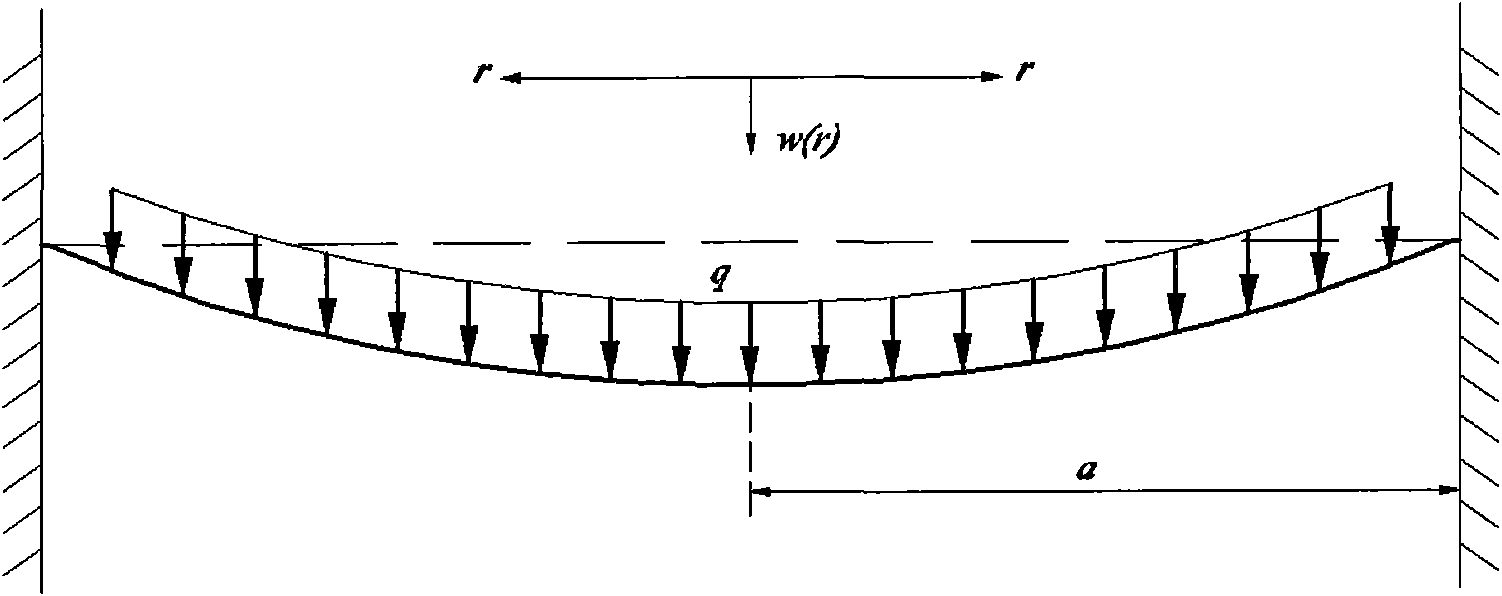

[0033] In 1915, Hencky gave the analytical solution of the circular film clamped around the periphery under the action of uniform load. In 1948, Qian Weichang corrected one of the calculation errors. It is also one of the few accurate analytical solutions of the thin film structure so far. The mechanical model of the Hencky problem is as follows figure 1 As shown, where r represents the radial coordinate, w(r) represents the vertical deflection, a represents the radius of the circular film, and q represents the uniform load, and the units of each quantity adopt the International System of Units.

[0034] This invention adopts the mechanical model of Hencky problem ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com