Intelligent variable frequency control system of oil extractor

A technology of frequency conversion control and intelligent controller, which is applied in the direction of electrical program control, program control in sequence/logic controller, and production fluid, etc., which can solve the problems of increasing oil production cost, inability to supply liquid volume, pumping out, etc., and achieve improvement The effect of work efficiency, energy consumption minimization and output maximization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

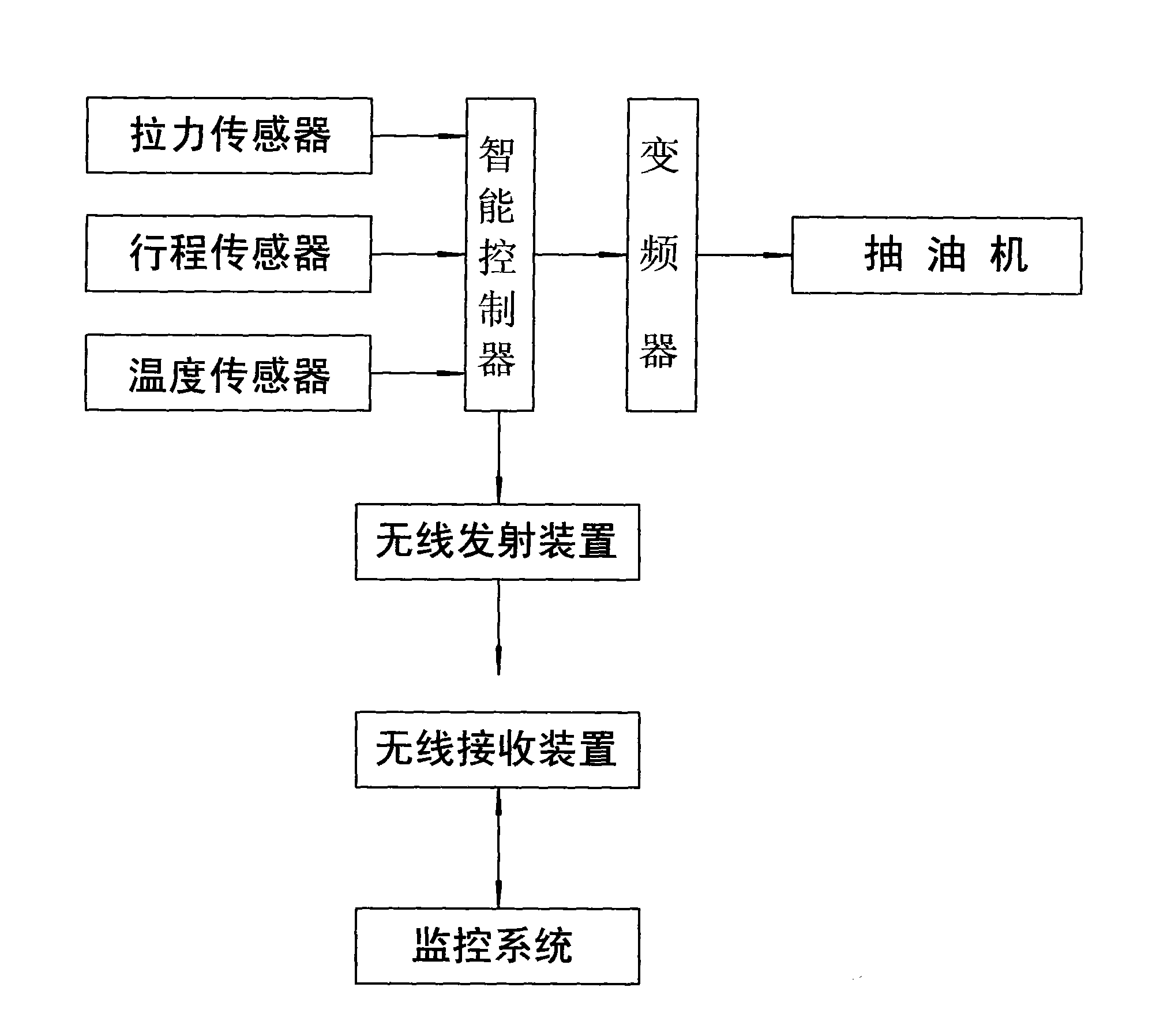

[0009] The specific implementation manner of the present invention will be described below with reference to the accompanying drawings. Such as figure 1 Shown: be provided with the frequency converter that joins with pumping unit the same as prior art, be connected with frequency converter with intelligent controller (microprocessor) differently with prior art, in the oil pumping unit of pumping unit A sucker rod pressure sensor and a sucker rod stroke sensor (rotary encoder) are arranged on the rod, and the sucker rod pressure sensor and the sucker rod stroke sensor are connected with an intelligent controller. The pressure sensor of the sucker rod automatically records the tension weight of the sucker rod, which provides data for the intelligent controller to measure the liquid level; Data; a temperature sensor can be installed next to the oil well or on the sucker rod to provide temperature data for the smart sensor. The intelligent controller interprets the data provided...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com