Label with hologram and method for preparing the same

A hologram and label technology, used in instruments, cardboard items, layered products, etc., can solve problems such as physical performance degradation, printing problems, and difficulty in use, and achieve stable physical properties, good holographic effects, and stable costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0059] Examples and comparative examples

[0060] The compositions of the films of Examples and Comparative Examples are as follows.

Embodiment 1

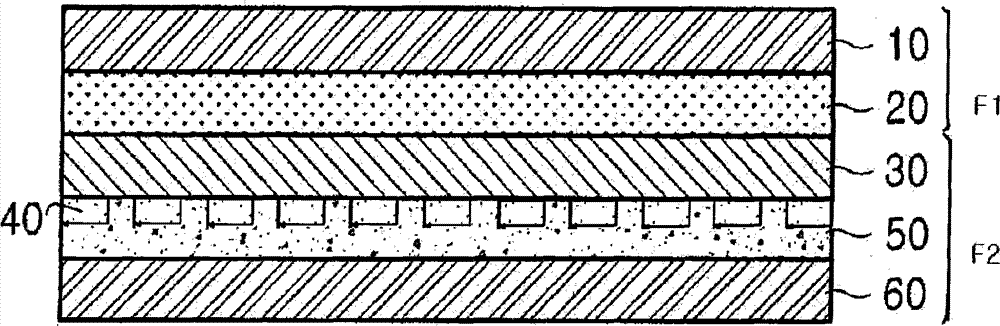

[0062] Base film 10 (OPP film with a thermal shrinkage rate of 0.5% in the film longitudinal direction) / printed layer 20 / aluminum deposition layer 30 / butyral resin primer layer 50 after embossing treatment 40 for forming a hologram / intermediate film 60 (white opaque OPP film) [see figure 1 ]

Embodiment 2

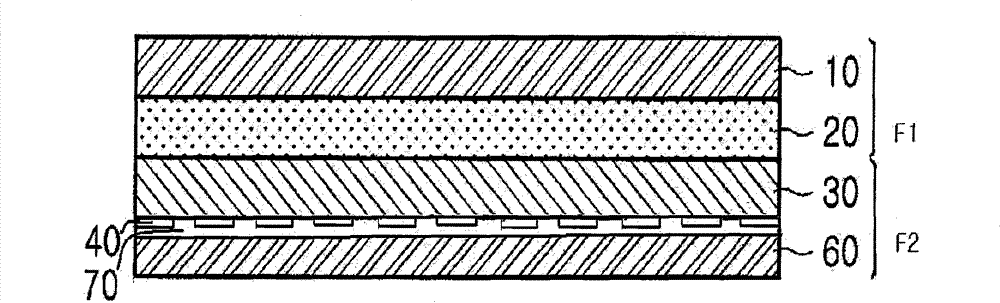

[0064] Base film 10 (OPP film with a thermal shrinkage rate of 0.5% in the film longitudinal direction) / printed layer 20 / aluminum deposition layer 30 / intermediate film 80 comprising a polyethylene resin surface layer and remaining polypropylene resin, which has an embossed surface layer 70 [See figure 2 ]

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com