Multichannel constant-current control circuit applicable to LED driver

A constant current control circuit, LED driver technology, applied in the direction of circuit layout, lamp circuit layout, electric light source, etc., can solve the problems of high design cost, expensive certification fee, payment, etc., and achieve the effect of simple structure and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

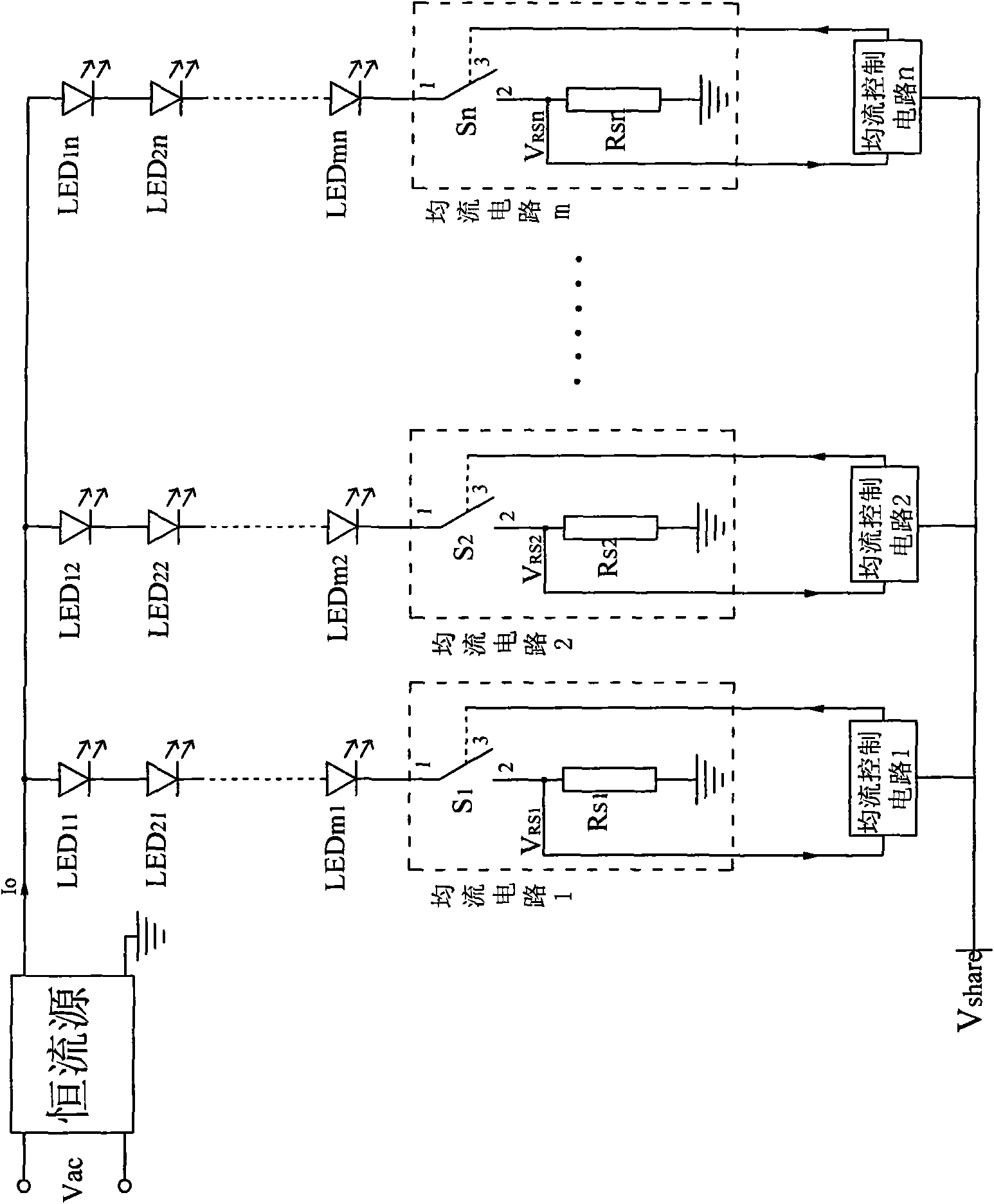

[0027] refer to Figure 4 , the AC input voltage Vac is used as the input of the constant current source, and after passing through the constant current source, the constant current (Io) is output to supply power to various LED loads. The LED load is composed of multiple (n) multiple (m) LED lamps connected in series (such as LED11, ... LEDm1, ..., LED1n, ... LEDmn). For the convenience of description, here we take the first (1) of n LED loads as an example for illustration.

[0028] The loads LED11, . . . LEDm1 are connected in series to the current equalizing circuit 1 composed of the adjusting tube S1 and the sampling resistor Rs1.

[0029] The first end of the adjustment tube (MOSFET) S1 of the current equalizing circuit 1 is connected to the LED load, the second end of the adjustment tube S1 is connected to the sampling resistor Rs1, the other end of the sampling resistor Rs1 is connected to the output ground, and the constant current source output ground connected.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com