Burner for production of inorganic sphericalized particle

A technology of spheroidization and inorganic substances, which is applied in the direction of burners, gas fuel burners, combustion methods, etc., can solve the problem of insufficient burners, etc., to prevent the reduction of the amount that can be spheroidized, high safety, and easy operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0068] Hereinafter, the present invention will be described in more detail with reference to examples, but the present invention is not limited by these examples.

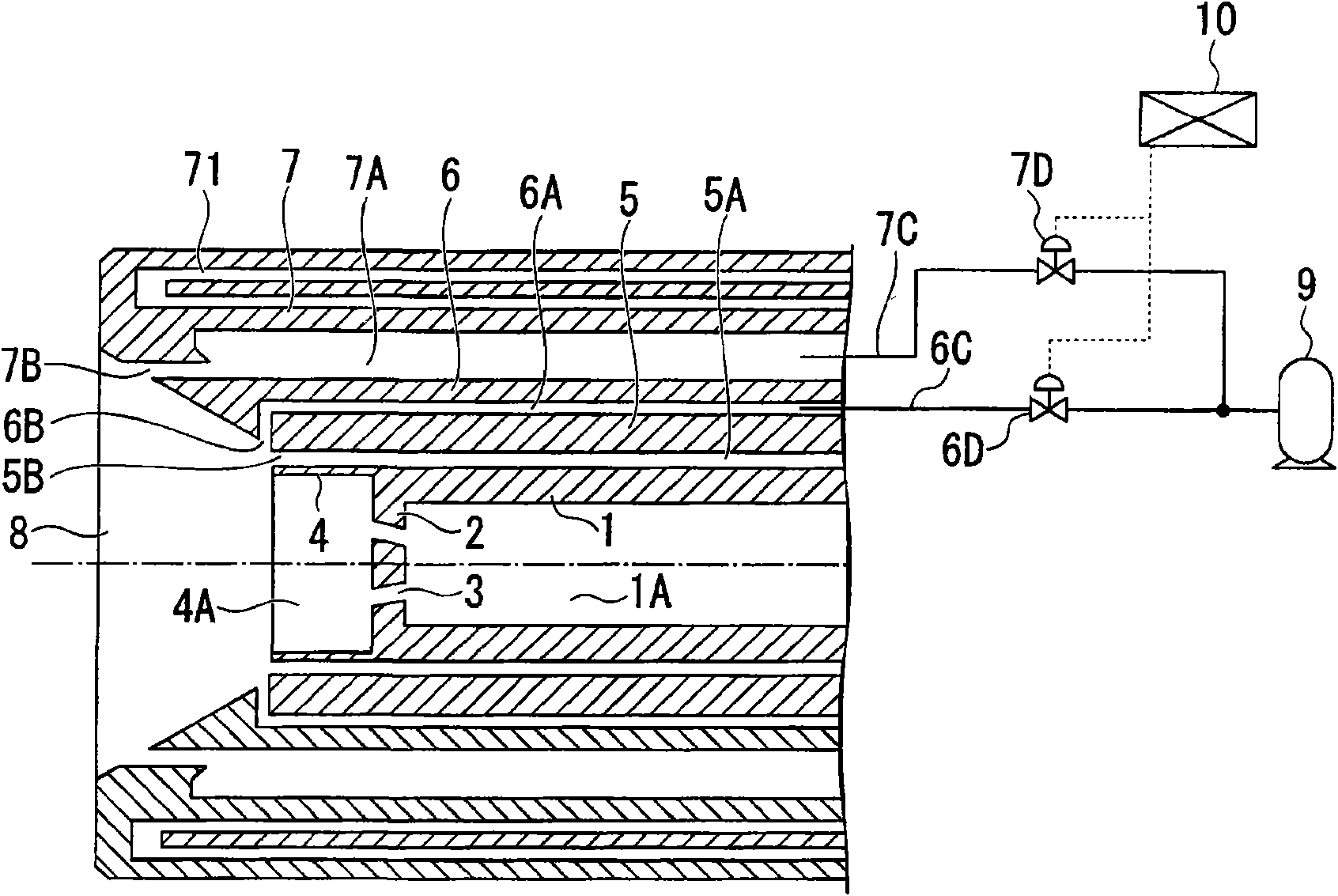

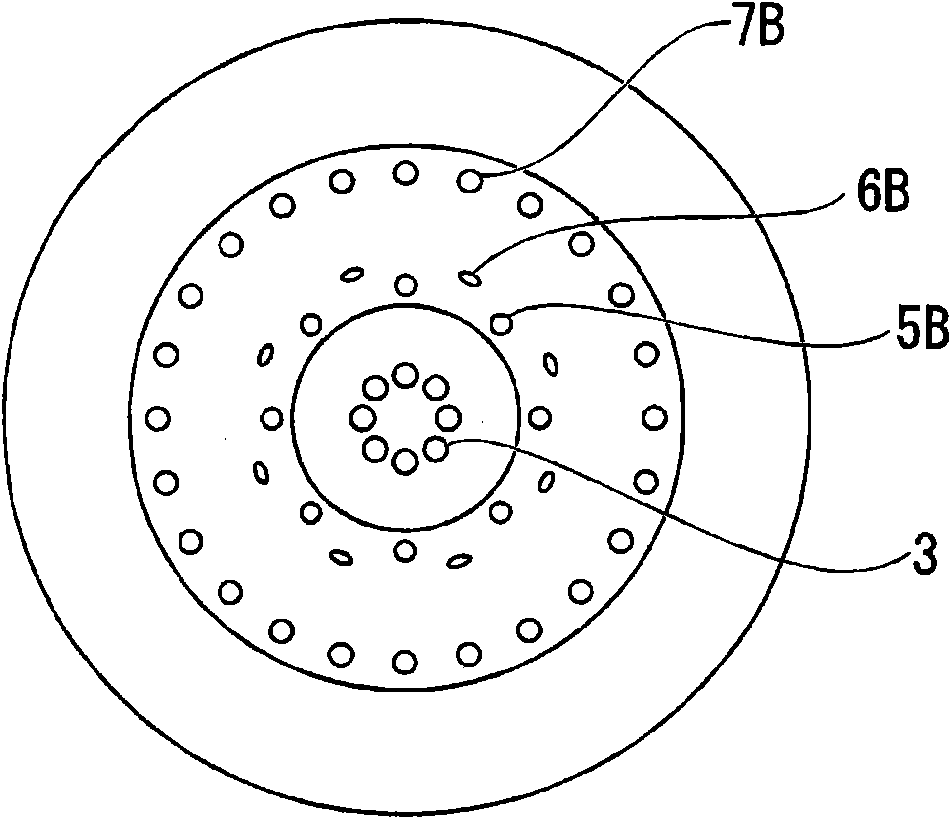

[0069] will figure 1 with figure 2 The burner of the present invention shown is configured in image 3 In the furnace top of the vertical furnace E of the shown inorganic spheroidized particle production apparatus, the raw material powder cut by the raw material supply machine A is supplied to the burner B and spheroidized in the vertical furnace E.

[0070] Specifically, the raw material supply path 1A uses 20 kg / h of silica powder as raw material powder to use 7.5 Nm 3 / h of oxygen (carrier gas) is transported and introduced into the raw material dispersion chamber 4A through the powder dispersion plate 2. In addition, the LPG as fuel gas is reduced to 5Nm from the fuel supply path 5A. 3 / h is introduced into the combustion chamber 8, which is 20Nm from the primary oxygen supply path 6A and the secondary oxygen supply...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com