Tea leaf fixation machine

A technology for a greening machine and tea, applied in the direction of tea treatment before extraction, can solve the problems of increasing production costs and operating costs, a large amount of dust and smoke during the combustion process, increasing the greening time and energy consumption, etc., so as to shorten the greening time and improve the service life, the effect of increasing the temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The detailed structure of the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

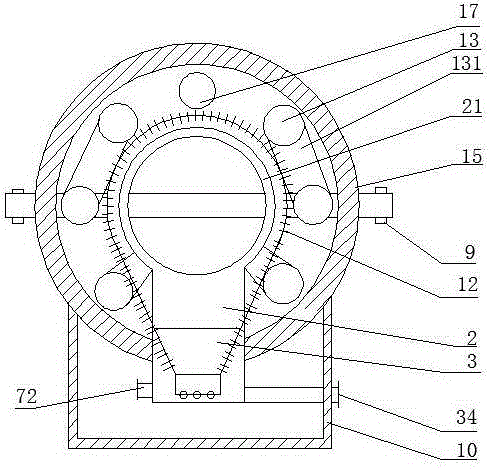

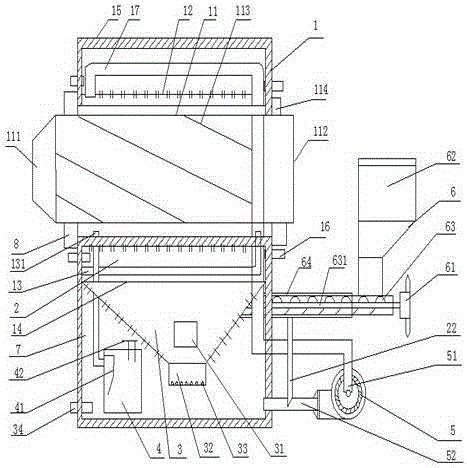

[0028] Such as figure 1 with figure 2 Shown: a tea greening machine, including a frame 10 and a furnace body 1 arranged on the frame 10; the furnace body 1 sequentially includes a drum 11, a sieve plate heat exchange plate 12, a flue pipe 13, a heat conducting Board 14 and insulation board 15. The drum 11 is made of steel plate with good thermal conductivity. One end of the drum 11 is provided with a tea inlet 111, and the other end is provided with a tea outlet 112. The inner wall of the drum 11 is provided with a tea feeding screw 113 for deriving the finished tea leaves from the tea outlet 112. The outer side of the drum 11 is provided with a supporting roller 8, and the supporting roller 8 supports the drum 11 and is placed horizontally on the supporting roller 9, and the position is limited by the supporting r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com