Thermoplastic resin composition having superior flame retardancy, coloring property and scratch-resistance

一种热塑性树脂、阻燃性的技术,应用在具有优异的阻燃性、可着色性和抗刮性的热塑性树脂组合物领域,能够解决抗刮性降低、易被划伤等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

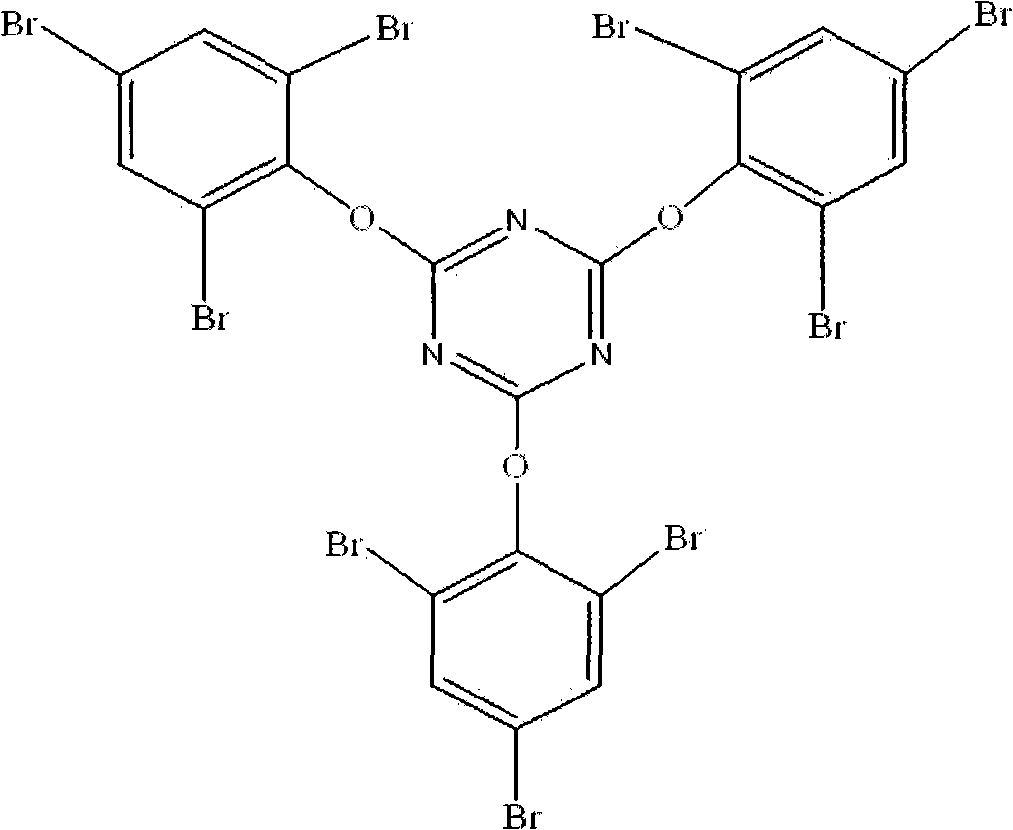

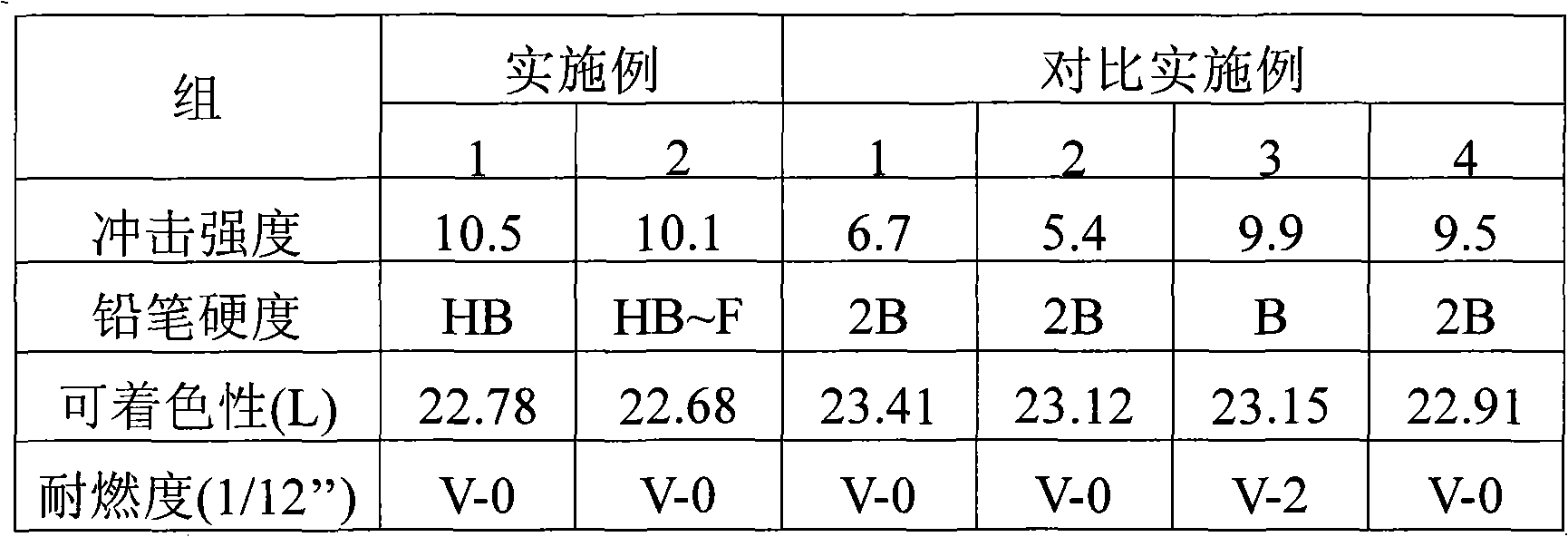

[0033] The thermoplastic resin composition is prepared in granular form by the following steps: 20 parts by weight of tris(tribromophenyl) cyanurate as a brominated organic flame retardant and 3 parts by weight of antimony trioxide as an auxiliary flame retardant , 3 parts by weight of black colorant, 0.3 parts by weight of antioxidant, 1.5 parts by weight of lubricant and 0.1 parts by weight of anti-dripping agent are added to 100 parts by weight of base resin, mixed evenly with a Hansel mixer, and then double Extruded by a screw extruder, the base resin is composed of the following ingredients: 20wt% ABS copolymer (DP270 manufactured by LG Chemical Company), which is prepared by emulsification graft polymerization using butadiene latex with an average diameter of 0.3 μm ; 70wt% styrene-acrylonitrile copolymer, its acrylonitrile content is 25wt% and the weight average molecular weight is 120,000; and 10wt% methyl methacrylate polymer (EH910 manufactured by LG MMA), its weight a...

Embodiment 2

[0035] Except that 60% by weight of styrene-acrylonitrile copolymer and 20% by weight of methyl methacrylate polymer were used in Example 1 above, Example 2 was performed in the same manner as Example 1 above.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com