Perfluoropolyether lubricant thin film for thin film storage medium

A technology of perfluoropolyether and magnetic recording medium, applied in the field of magnetic recording medium and lubricating oil, can solve the problems of weak anti-wear property and no molecular mobility of perfluorocarbon polymer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention relates to a method of coating a substrate, in particular a recording medium (recording disk), with a solid lubricant, where lubricant is also specifically referred to as lube. Lubricants are typically liquids containing components with molecular weights ranging from a few hundred Daltons to several thousand Daltons.

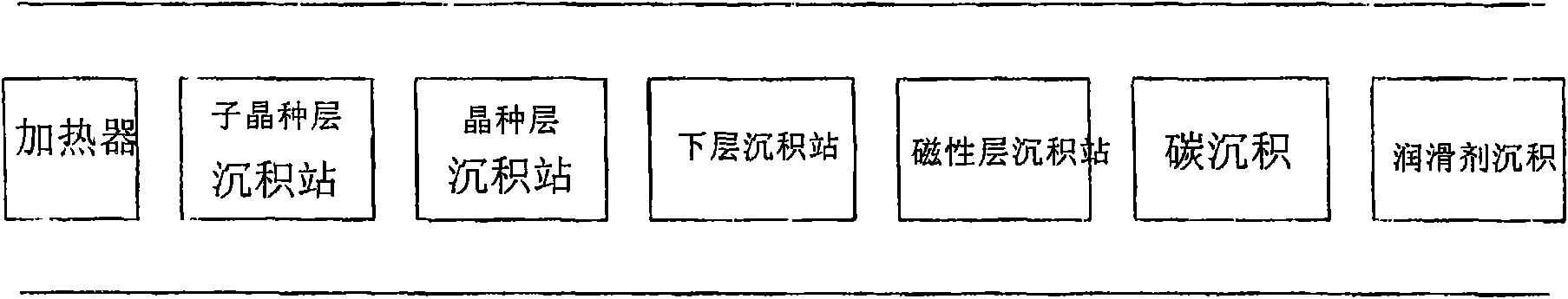

[0028] In-house processing for the manufacture of magnetic recording media in image 3 is schematically shown in . The disk substrate is continuously moved from the heater to the sub-seed layer deposition station so that the sub-seed layer is formed on the disk substrate. The disk substrate then moves to a seed layer station to deposit a seed layer, typically NiAl. Following deposition of the sub-seed layer and seed layer, the disk substrate is transported through an underlayer deposition station where the underlayer is deposited. The disks are then transported to a magnetic layer deposition station, followed by a protective carbo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com