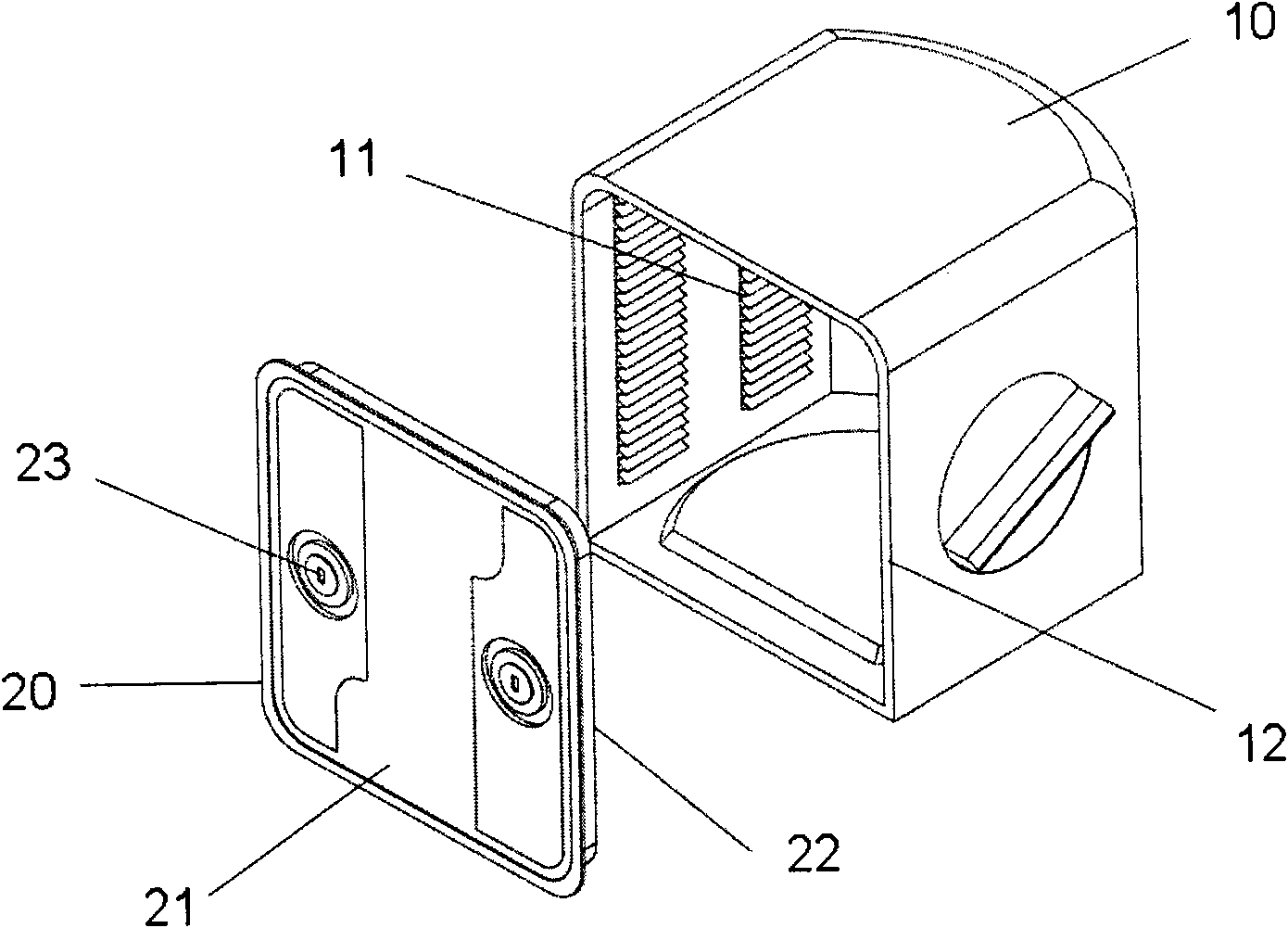

Front opening type wafer box with elliptic latch structure

A front-opening, elliptical cam technology is used in building structures, removable covers/covers, containers to prevent mechanical damage, etc. Problems such as the manufacturing cost of the film cassette and the inability to snap into the cassette body 10

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

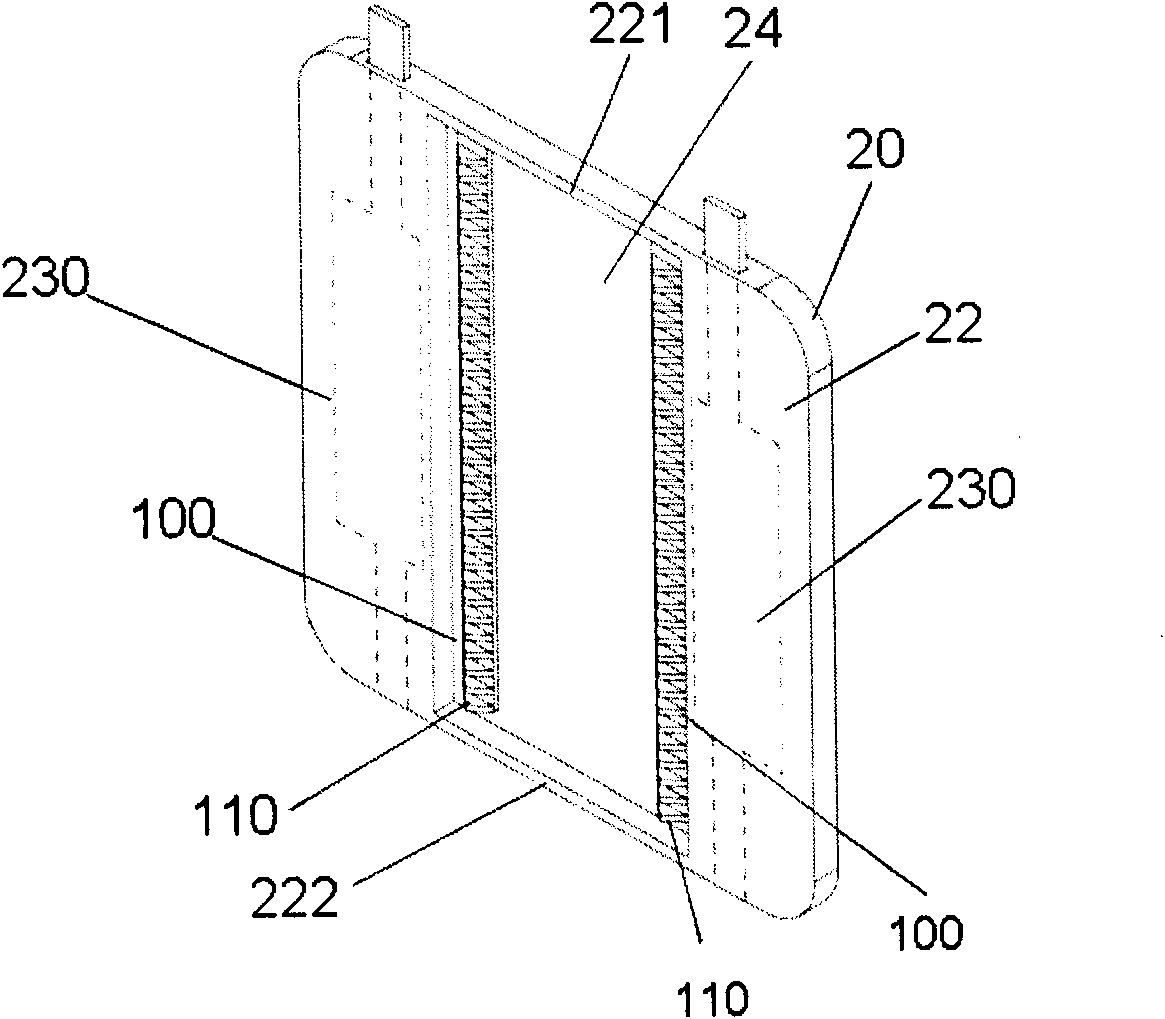

[0061] In order to fully and clearly disclose the technical content used in the present invention, the purpose of the invention and the effects achieved, the following detailed description is provided with the accompanying drawings.

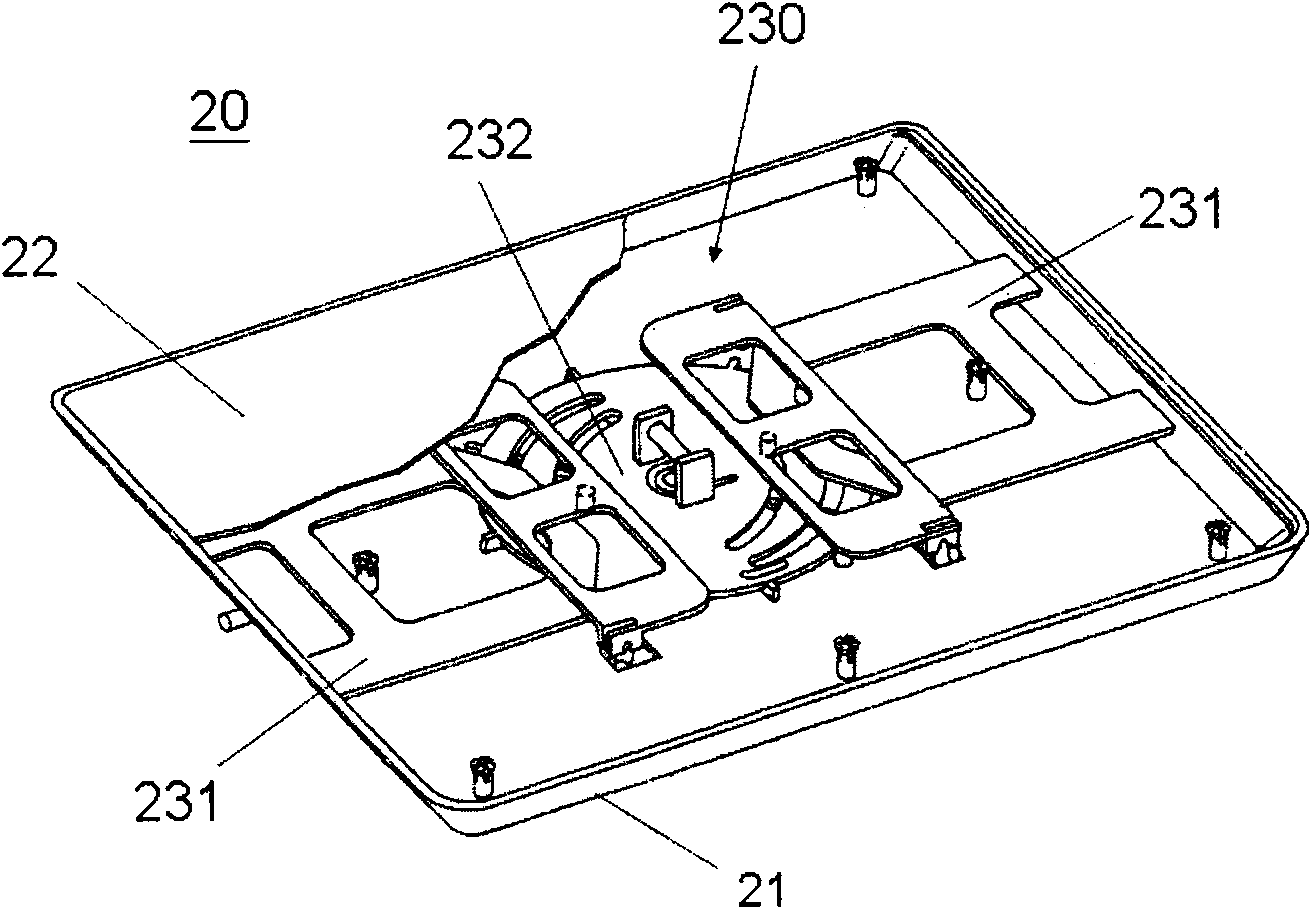

[0062] Please refer to Figure 5 , is a top view of the latch structure 60 of a door body 20 of the front opening wafer cassette of the present invention. Such as Figure 5 As shown, a pair of latch structures 60 are included between the outer surface and the inner surface of the door body 20, wherein each latch structure 60 consists of an elliptical cam 62, a pair of sliding devices 64 in contact with both ends of the elliptical cam 62, at least one pulley 66 is disposed between the outer surface and the inner surface of the door body 20 and is embedded in the slide groove 642 of the sliding device 64 and at least one positioning elastic piece 68 integrally connected with the sliding device 64 . Next, please refer to Figure 6 ,yes Figure 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com