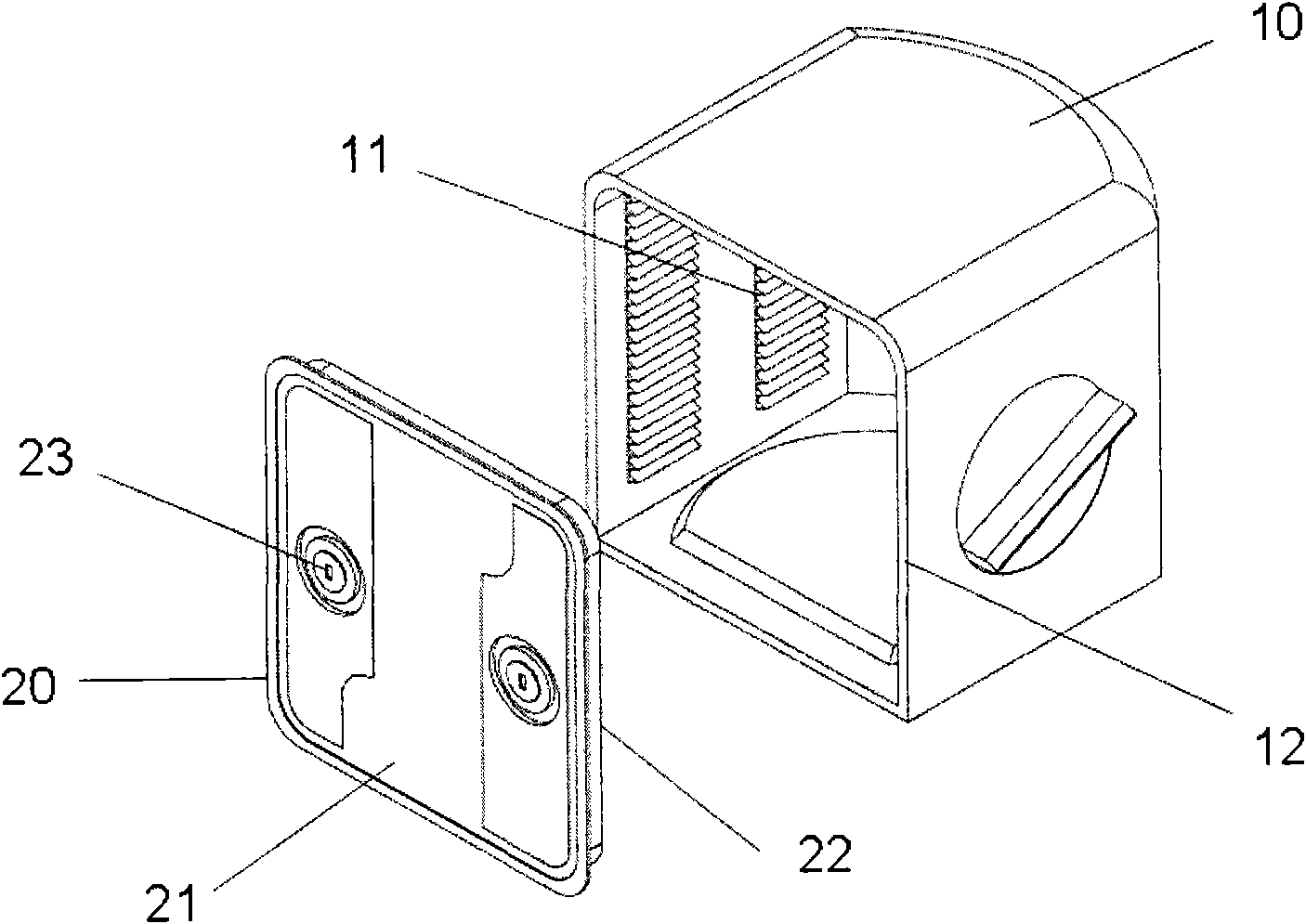

Front-open type disc plate box with bolt structure

A front-opening, wafer technology, which is applied in the field of front-opening wafer boxes, can solve the problem that the box body 10 and the door body 20 cannot be closed, increase the manufacturing cost of the front-opening wafer box, and cannot be inserted into the box body 10. And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

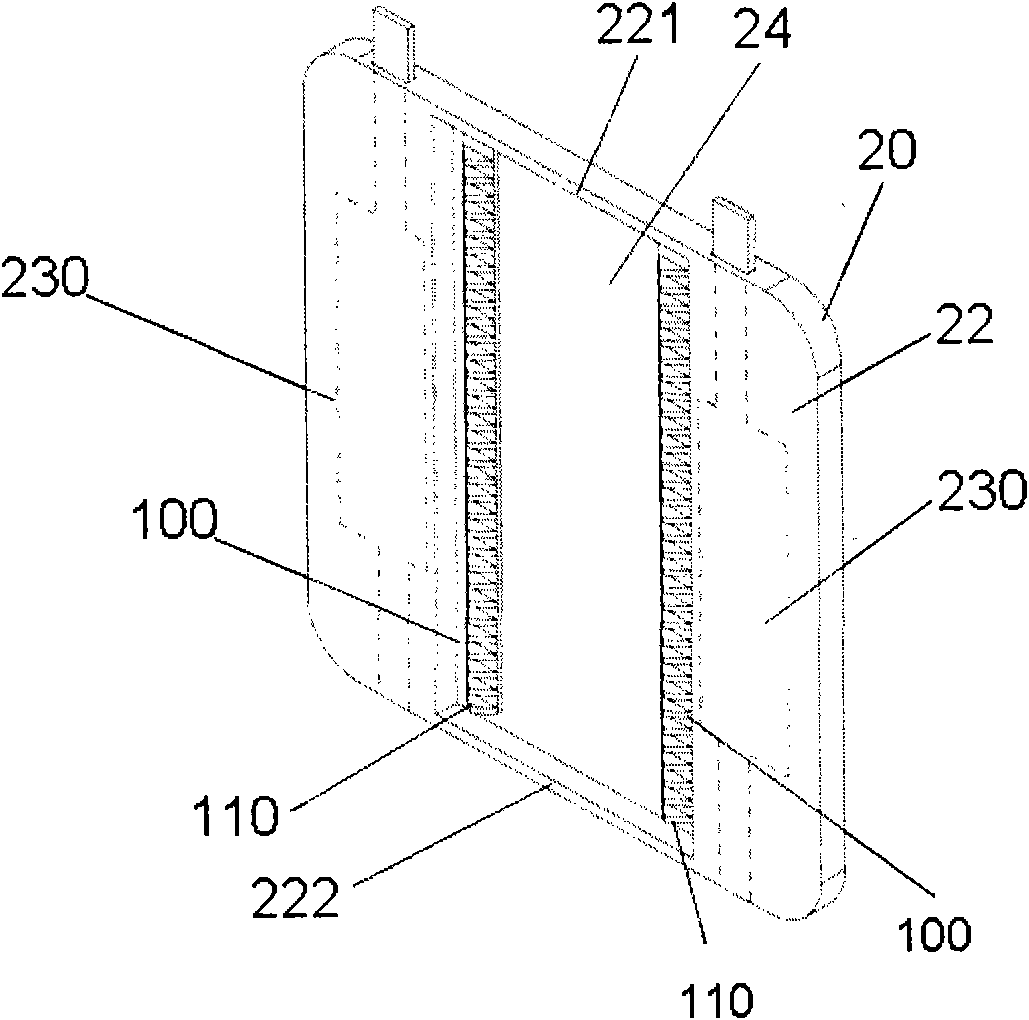

[0064] In order to have a more complete and clear description of the technical content used in the present invention, the purpose of the invention and the effects achieved, the details are described below with the accompanying drawings.

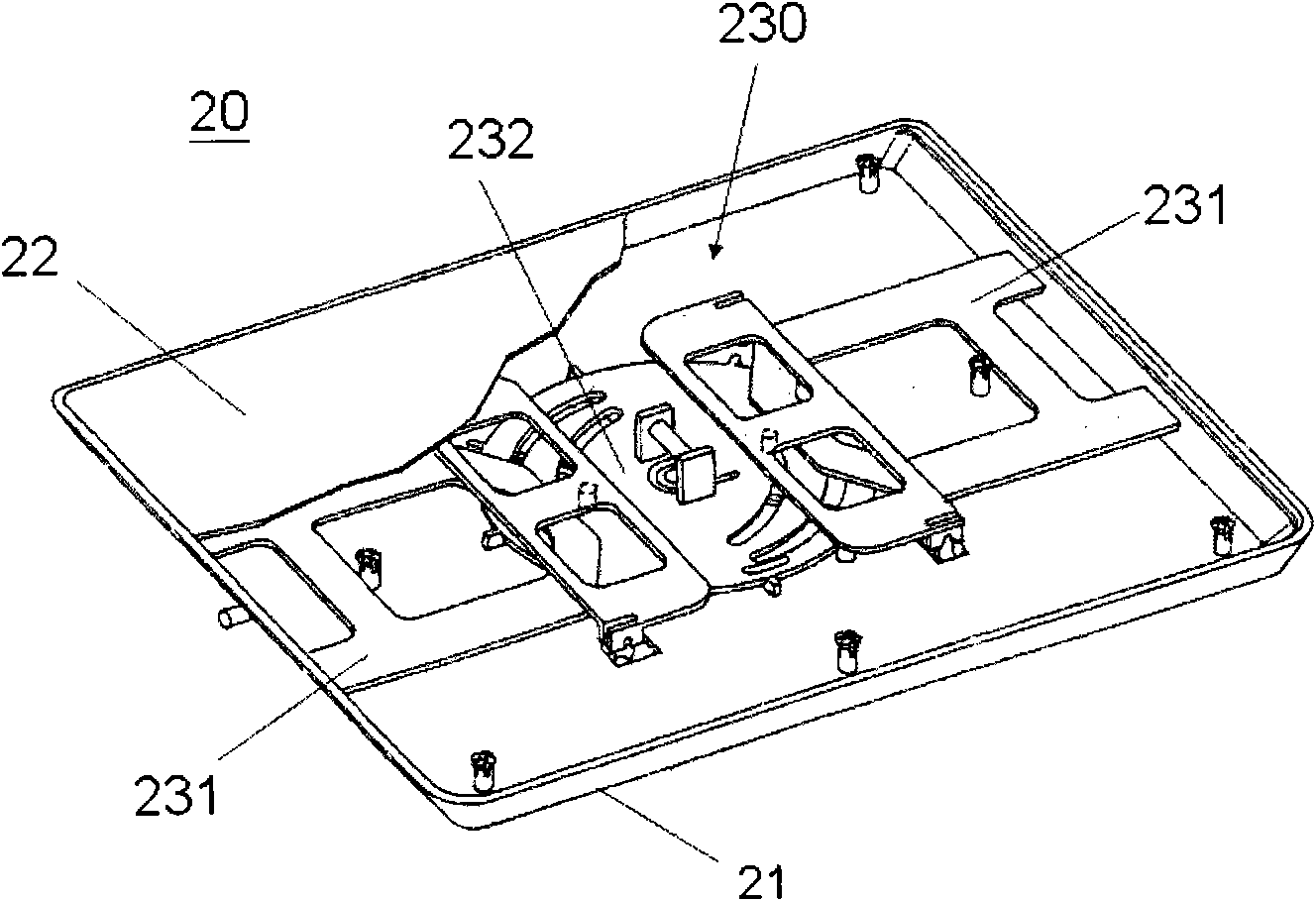

[0065] Please refer to Figure 5 , is a schematic diagram of a door of the front-opening wafer cassette of the present invention. Such as Figure 5 As shown, the door body 20 includes a pair of latch structures 60, and each latch structure 60 includes a cam 62 and a pair of sliding devices 64 buckled with both ends of the cam 62, wherein the cam 62 is provided with a pair of guide grooves 621 to The corresponding sliding device 64 is provided for fastening, and each sliding device 64 has a slide groove 642 for the pulley 66 disposed between the outer surface and the inner surface of the door body 20 to be embedded.

[0066] Next, please refer to Figure 6A ,yes Figure 5 The enlarged schematic diagram of the contact end of the cam 62 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com