Dry cheese and process for producing the same

A manufacturing method and cheese technology, applied in cheese substitutes, dairy products, applications, etc., can solve problems such as inability to dry and difficulty in cheese, and achieve the effects of uniform tissue, excellent preservation, and shortened drying time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

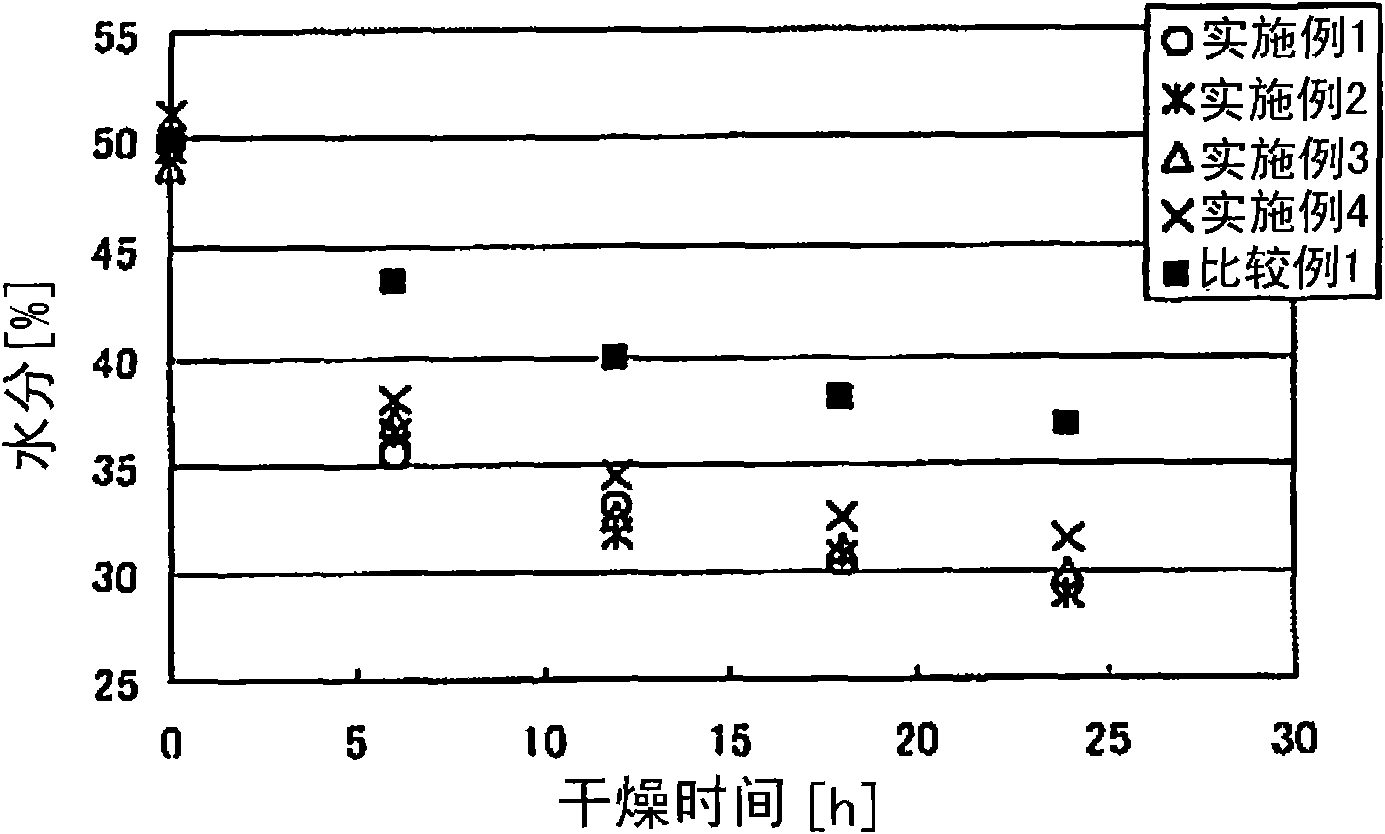

Embodiment 1

[0041] Get 100kg of raw milk whose fat content is adjusted to 2.8%, heat sterilization at 60° C. for 30 minutes, add 0.1% of 3% rennet (HR chymosin: CHR.HANSEN company) solution, and make cheese curd. The above-mentioned curd cheese was crushed into cubes of 10 mm, and the whey was removed while stirring slowly, and then immersed in a 1.0% acetic acid solution for 5 minutes. This cheese curd is pressed and dehydrated, kneaded and formed in hot water. Furthermore, cold-air drying was performed for 24 hours at a temperature of 10° C. and a humidity of 70%, thereby obtaining the cheese of the present invention. The change of cheese moisture with time during the drying process was measured. In addition, the protein content, calcium content and pH value of the dried cheese were measured, and the texture and mouthfeel were evaluated sensorily.

Embodiment 2

[0043] Get 100kg of raw milk whose fat content is adjusted to 2.8%, heat sterilization at 60°C for 30 minutes, add 100g of lactic acid bacteria starter (starter culture) (CHR.HANSEN company) to it, add 0.1% of 3% rennet (HR Rennet: CHR.HANSEN Company) solution to prepare cheese curd. The above-mentioned curd cheese was broken into cubes of 10 mm, and after stirring continuously at 37°C for 5 hours, the whey was removed, dehydrated by pressing, and kneaded in hot water to shape. Furthermore, cold-air drying was performed for 24 hours at a temperature of 10° C. and a humidity of 70%, thereby obtaining the cheese of the present invention. The change of cheese moisture with time during the drying process was measured. In addition, the protein content, calcium content and pH value of the dried cheese were measured, and the texture and mouthfeel were evaluated sensorily.

Embodiment 3

[0045] Commercially available Gouda cheese (Gouda cheese) was broken into about 1 cm square, and soaked in 1.0% acetic acid solution for 5 minutes. The cheese is then kneaded and shaped in hot water. Furthermore, cold-air drying was performed for 24 hours at a temperature of 10° C. and a humidity of 70%, thereby obtaining the cheese of the present invention. The change of cheese moisture with time during the drying process was measured. In addition, the protein content, calcium content and pH value of the dried cheese were measured, and the texture and mouthfeel were evaluated sensorily.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com