Fluororesin tube and process for producing the same

A fluororesin, tube-shaped technology, applied in the direction of tube-shaped articles, other household appliances, applications, etc., can solve problems such as cracking or tearing, and achieve the effect of excellent wall thickness accuracy and low degree of orientation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0077] A PFA tube having an outer diameter of 150 mm and an average thickness of 29 μm was produced by melt-extruding PFA having a melting point of 310° C. (MFR = 2.1 g / 10 minutes) through an annular die as described below.

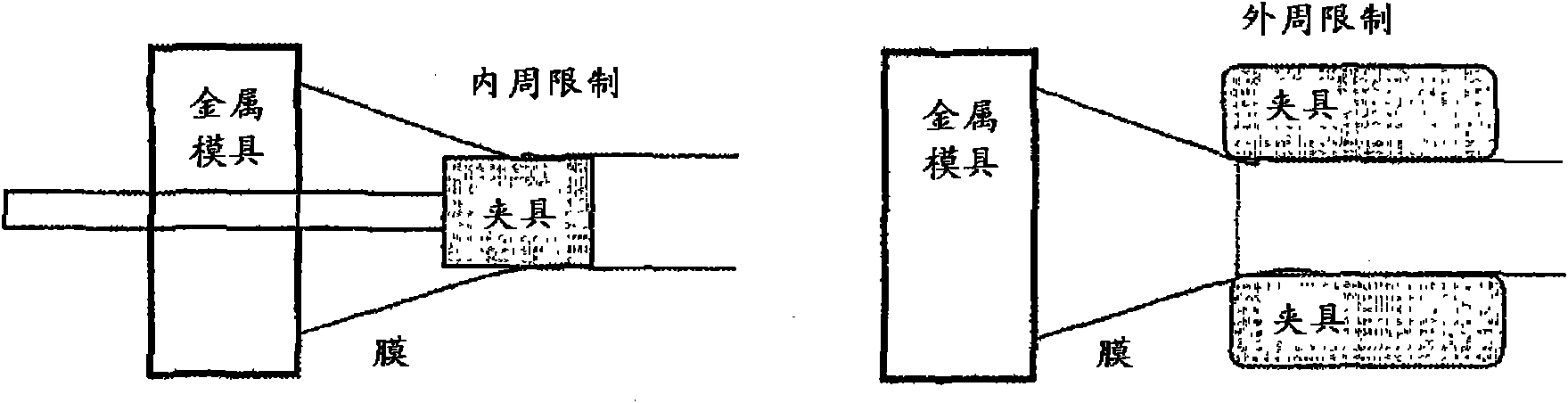

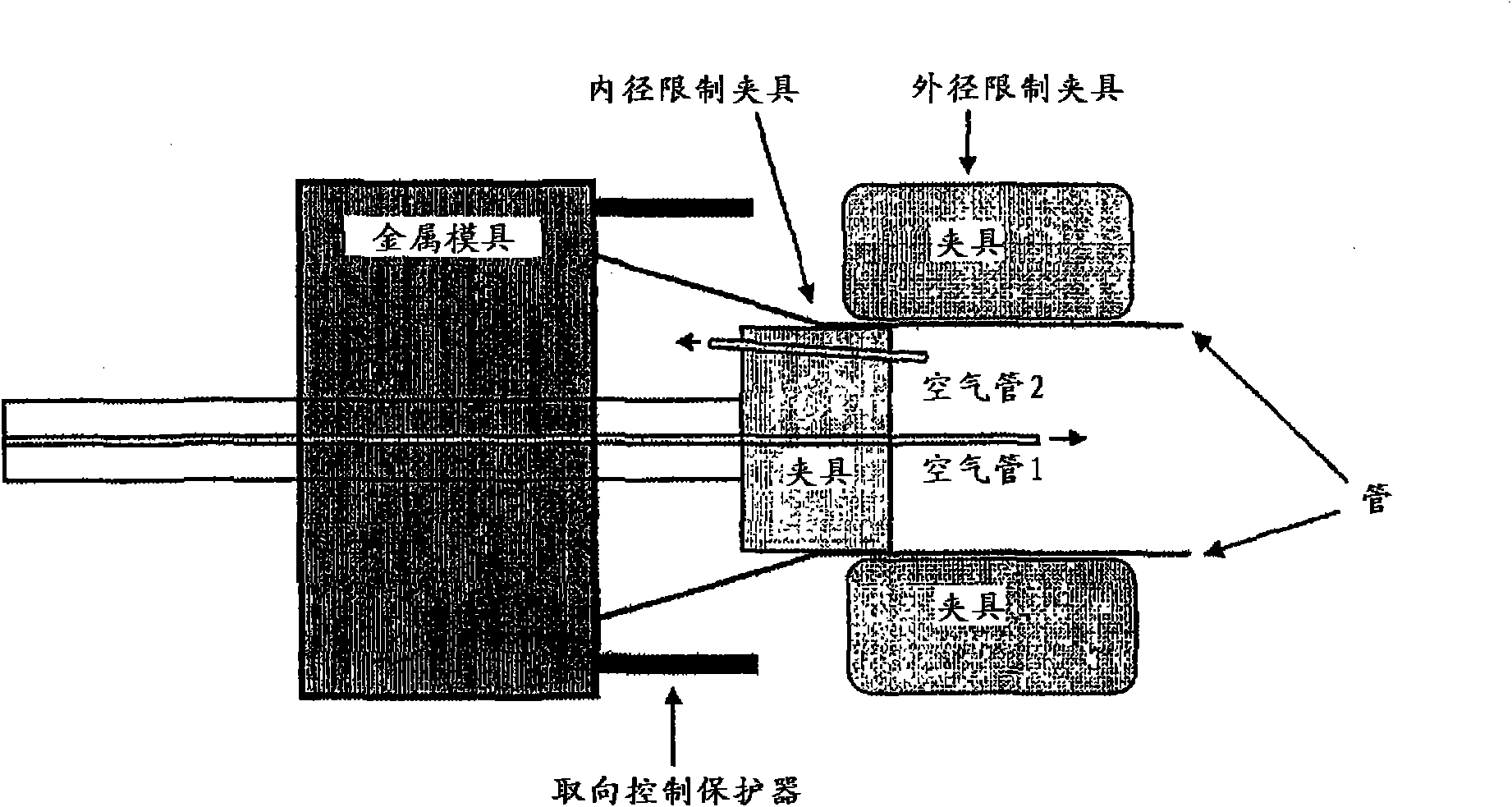

[0078] Two diameter limiting jigs are provided to cool and solidify the tube melt extruded through the annular die and limit the tube diameter to a specific value. In addition, a cylindrical metal protector is provided to enclose the tube in the area where the tube comes into contact with the clamp. see figure 2 .

[0079] First, the inner surface of the extruded tube is placed in contact with a first cooling and diameter limiting jig. Cooling water flows (circulates) inside the fixture. The center of the support rod of the clamp is provided with a tube hole through which air can be introduced. Air at room temperature was introduced through the tube bore to apply internal pressure to prevent the tube from sagging after contact with the inner diameter...

Embodiment 2

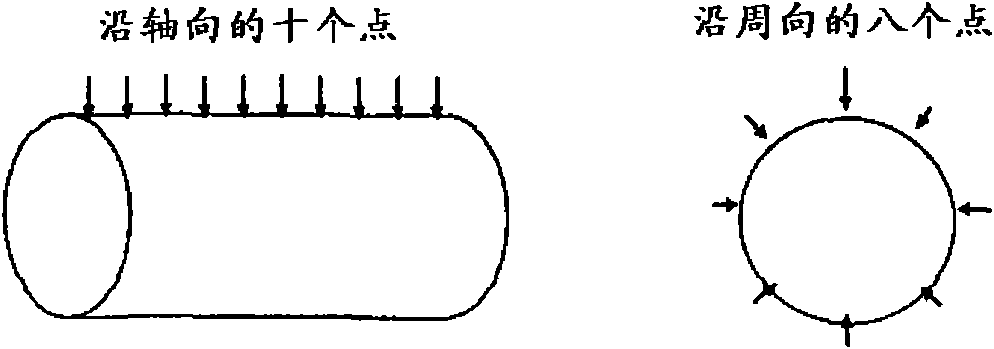

[0083] A PFA tube was manufactured in the same manner as in Example 1 except that the outer diameter of the PFA tube was 165 mm and the thickness was 33 μm.

[0084] The average thickness of the resulting tube was 33 μm. The measured tube thickness at each of the 80 points was within ±9.1% of the average thickness of the tube. The degree of orientation (F) of the tube was 0.50.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com