Composite plastic woven bag

A technology of compounding plastics and woven bags, applied in the directions of bags, sacks, synthetic resin layered products, etc., can solve problems such as damage to food quality, and achieve the effects of prolonging service life, low crystallinity and orientation, and large water absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

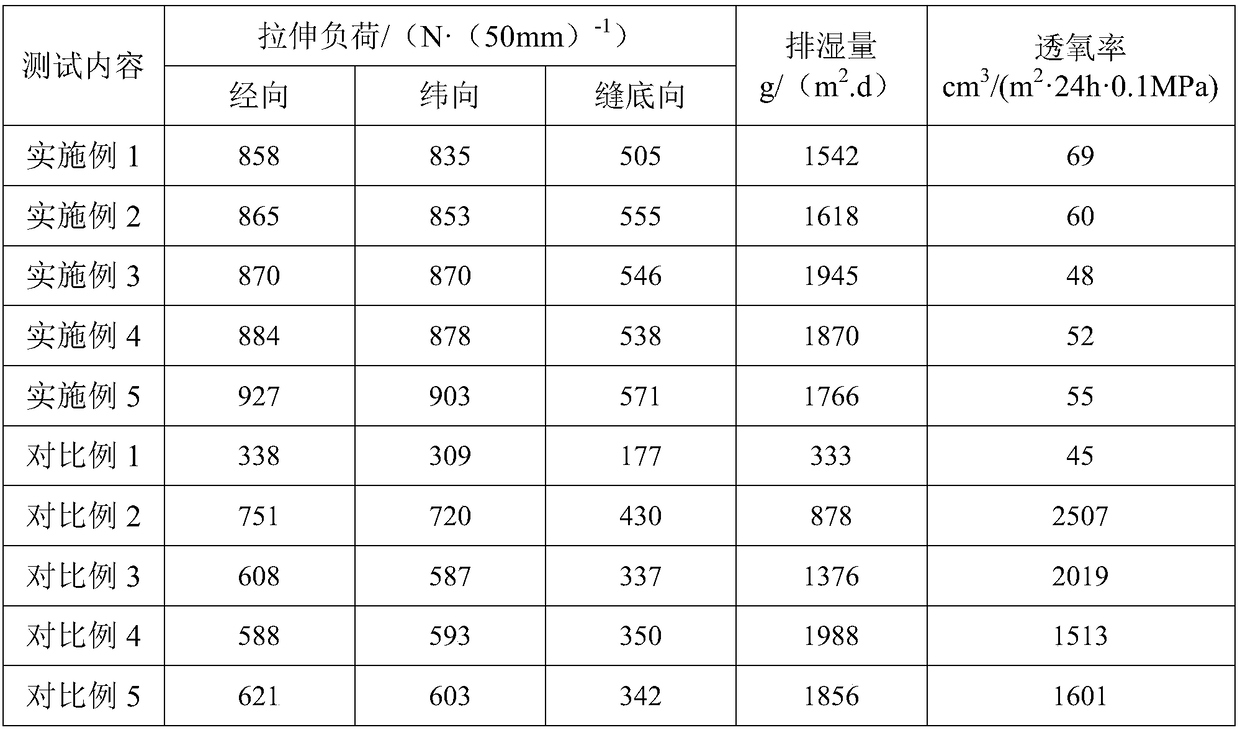

Examples

Embodiment 1

[0031] A composite plastic woven bag, which consists of a water-absorbing layer, a braided layer and a protective layer from the inside to the outside;

[0032] The water-absorbing layer includes the following raw materials in weight percent: 55 parts of polyurethane pellets, 20 parts of polyethylene, 7 parts of banana fiber, 0.5 part of coupling agent, 0.5 part of anti-aging agent, 0.5 part of antioxidant, 0.1 part of chlorinated polyethylene part; the banana fiber is pretreated with cellulase liquid. The thickness of the water-absorbing layer is 30 μm.

[0033] The braided layer includes the following raw materials in weight percentage: 60 parts of polypropylene pellets, 20 parts of polyethylene, 5 parts of coolmax fiber, 0.5 part of coupling agent, 0.5 part of anti-aging agent, 0.5 part of antioxidant, chlorinated polyethylene 0.1 part. The thickness of the braided layer is 0.1 mm.

[0034] The protective layer includes the following raw materials in weight percentage: 8...

Embodiment 2

[0036] A composite plastic woven bag, which consists of a water-absorbing layer, a braided layer and a protective layer from the inside to the outside;

[0037] The water-absorbing layer includes the following raw materials in weight percent: 60 parts of polyurethane pellets, 22 parts of polyethylene, 9 parts of banana fiber, 1 part of coupling agent, 0.8 part of anti-aging agent, 1 part of antioxidant, 0.2 part of chlorinated polyethylene part; the banana fiber is pretreated with cellulase liquid. The thickness of the water-absorbing layer is 45 μm.

[0038] The braided layer includes the following raw materials in weight percentage: 62 parts of polypropylene pellets, 22 parts of polyethylene, 7 parts of coolmax fiber, 1 part of coupling agent, 0.8 part of anti-aging agent, 1 part of antioxidant, chlorinated polyethylene 0.2 part; the thickness of the braided layer is 0.2mm.

[0039] The protective layer includes the following raw materials in weight percentage: 80-90 parts...

Embodiment 3

[0041] A composite plastic woven bag, which consists of a water-absorbing layer, a braided layer and a protective layer from the inside to the outside;

[0042] The water-absorbing layer includes the following raw materials in weight percent: 65 parts of polyurethane pellets, 25 parts of polyethylene, 10 parts of banana fiber, 1.5 parts of coupling agent, 1.2 parts of anti-aging agent, 1.5 parts of antioxidant, 0.3 parts of chlorinated polyethylene part; the banana fiber is pretreated with cellulase liquid. The thickness of the water-absorbing layer is 60 μm.

[0043] The braided layer includes the following raw materials in weight percentage: 65 parts of polypropylene pellets, 25 parts of polyethylene, 8 parts of coolmax fiber, 1.5 parts of coupling agent, 1.2 parts of anti-aging agent, 1.5 parts of antioxidant, chlorinated polyethylene 0.3 parts; the thickness of the braided layer is 0.25mm.

[0044] The protective layer includes the following raw materials in weight perce...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com