Preparation method of high-modulus poly (p-phenylene benzobisoxazole) fiber

A technology of benzobisoxazole and poly-p-phenylene, which is applied in the field of preparation of high-modulus poly-p-phenylene benzobisoxazole fiber, can solve the problem of low orientation degree of PBO fiber core layer, increase of fiber orientation degree and strength , poor flexibility and other issues, to achieve the effect of compact structure, increased orientation and strength, and favorable movement and closed loop

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Add carbon nanotubes in the beaker that fills (volume concentration) 45% sulfuric acid aqueous solution, the addition of carbon nanotubes is 4wt% of 45% sulfuric acid aqueous solution, then beaker is placed in the oil bath of 50 ℃, to the inside of beaker The solution was continuously stirred for 2 hours, and the sulfuric acid solution was removed by centrifugation with a high-speed centrifuge, the centrifuge speed was 7000r / min, and the time was 15min. The remaining carbon nanotubes were repeatedly washed with deionized water until neutral, and then the obtained carbon nanotubes The tubes were dried in a vacuum oven at 80° C. for 9 hours to obtain carboxylated carbon nanotubes. The carbon nanotubes can also be oxidized with bromine water and dilute nitric acid.

[0030] The carboxylated carbon nanotubes in the following examples all adopt the carboxylated carbon nanotubes prepared in Example 1;

Embodiment 2

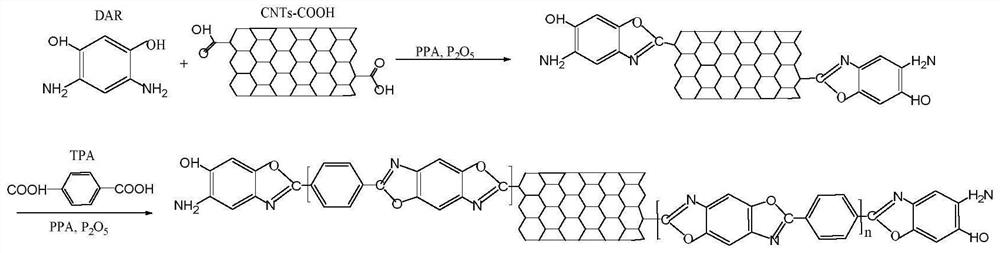

[0032] A kind of preparation method of high modulus poly-p-phenylene benzobisoxazole fiber, specifically comprises the steps:

[0033] (1) Add 10.048Kg of polyphosphoric acid solvent to a polymerization reactor with nitrogen gas, add 4.98g of carboxylated carbon nanotubes to the polyphosphoric acid solution, stir at 40°C for 3h, and then add 2.18Kg 4,6-diaminoresorcinol hydrochloride (DAR HCl), 3.861Kg phosphorus pentoxide (P 2 o 5 ), vacuumize the reaction kettle, supplement nitrogen three times, start the stirring reaction for 5h, then add 1.699Kg terephthalic acid (TPA), stir, and when the temperature of the system reaches 135°C, the prepolymerization is completed to obtain the PBO prepolymer solution. The intrinsic viscosity of PBO prepolymer solution is 0.78dl / g;

[0034](2) Transport the PBO prepolymer solution to the twin-screw extruder through the pipeline, and fill it with nitrogen for protection. The PBO prepolymer solution is highly polymerized in the twin-screw e...

Embodiment 3

[0039] A kind of preparation method of high modulus poly-p-phenylene benzobisoxazole fiber, specifically comprises the steps:

[0040] (1) Add 10.048Kg of polyphosphoric acid solvent to a polymerization reactor with nitrogen gas, add 9.96g of carboxylated carbon nanotubes to the polyphosphoric acid solution, stir at 40°C for 2 hours, and then add 2.18Kg 4,6-diaminoresorcinol hydrochloride (DAR HCl), 3.861Kg phosphorus pentoxide (P 2 o 5 ), vacuumize the reactor, replenish nitrogen three times, start stirring and reacting for 5 hours, then add 1.699Kg terephthalic acid (TPA), stir, and when the temperature of the system reaches 135°C, the prepolymerization is completed, and the PBO prepolymer solution is inherently viscous The number is 0.66dl / g;

[0041] (2) Transport the PBO prepolymer solution to the twin-screw extruder through the pipeline, and fill it with nitrogen for protection. The PBO prepolymer solution is highly polymerized in the twin-screw extruder to obtain the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| tensile strength at break | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com