Patents

Literature

47results about How to "Solve easy reunion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

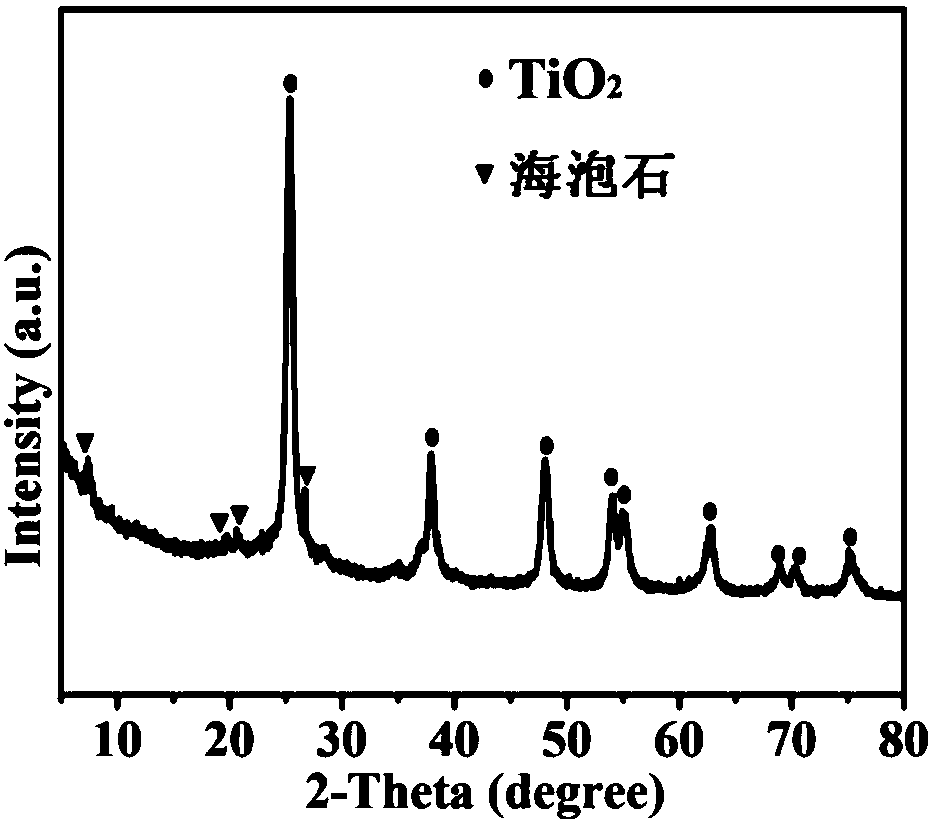

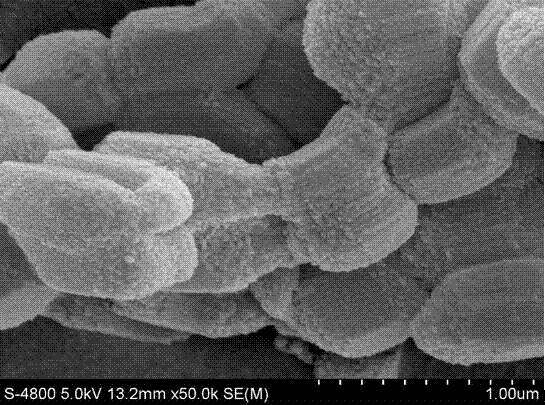

TiO2/sepiolite composite gel with 001 and 101 crystal planes exposed and preparation method of TiO2/sepiolite composite gel

ActiveCN108295830ANovel structureGood dispersionPhysical/chemical process catalystsWater/sewage treatment by irradiationCrystal planeSolvent

The invention relates to TiO2 / sepiolite composite gel and a preparation method thereof. The composite gel is of a 3D net structure, wherein 001 and 101 crystal planes of TiO2 in the composite gel areexposed, and 5%-50% of the 001 crystal plane is exposed. The preparation method of the composite gel comprises the following steps: a Ti source is hydrolyzed; a sepiolite dispersion is prepared; an aqueous surfactant solution is prepared; the three obtained mixed solutions are mixed and subjected to a solvothermal reaction, and the TiO2 / sepiolite composite gel with the 001 and 101 crystal planes exposed is obtained. The TiO2 / sepiolite composite gel is novel in structure, has high adsorptive property and photocatalytic activity and has broad application prospect in the purification field, TiO2dispersion is promoted, and the problem that solid-liquid separation is difficult for pure TiO2 powder is solved.

Owner:CHINA BUILDING MATERIALS ACAD

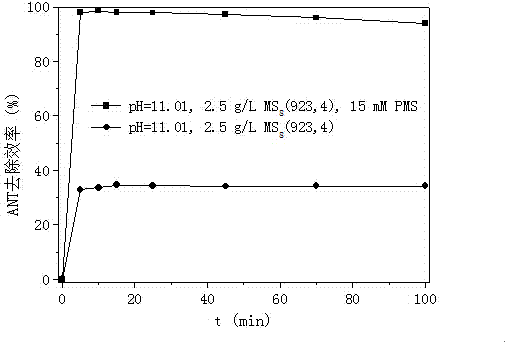

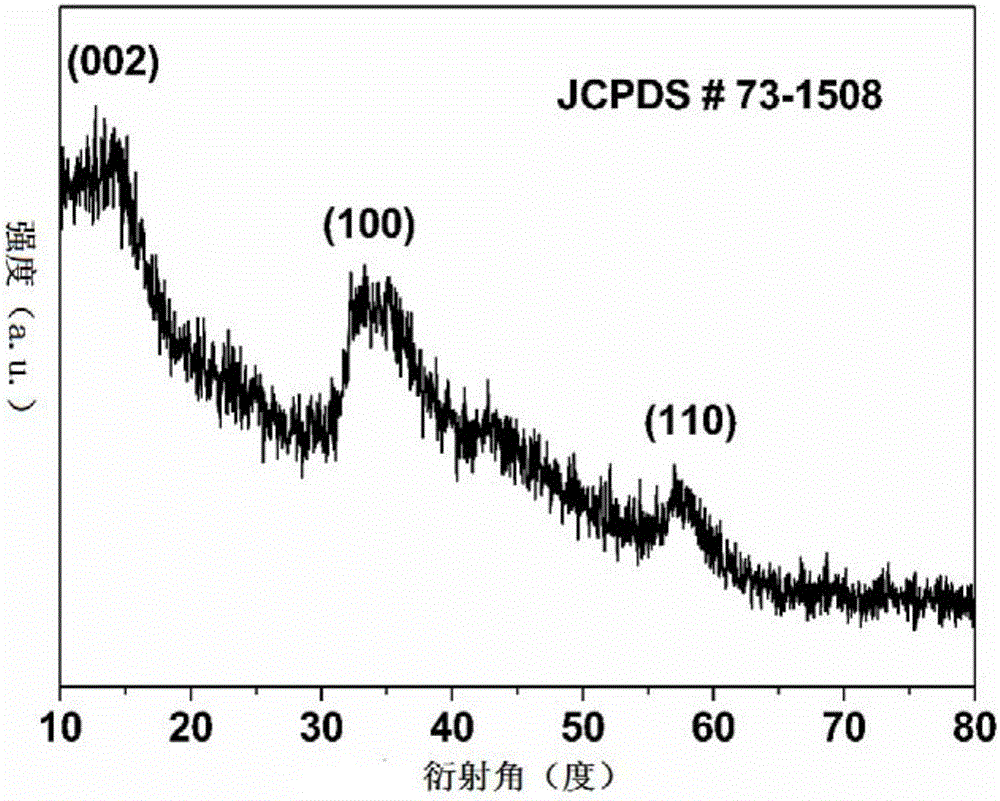

Method for efficiently and fast removing antipyrine by using MnOx/SBA-15-PMS compound system and application

ActiveCN104724815AGood effectEfficient removalMolecular sieve catalystsWater treatment compoundsHydrogen SulfatePotassium

The invention discloses a method for efficiently and fast removing antipyrine by using a MnOx / SBA-15-PMS compound system and application. The method comprises the following steps: (1) preparing MnOx / SBA-15(MS) compound materials under different synthesis conditions; (2) preparing a 0.5-50mg / L antipyrine target solution, and regulating the pH to 3-11; and (3) respectively adding a certain amount of MS compound material and potassium hydrogen sulfate (PMS) in the antipyrine target solution, and reacting under room temperature. The method disclosed by the invention firstly discovers that the MS-PMS catalytic oxidation compound system is capable of fast and effectively removing the antipyrine, and capable of maintaining high removal rate (more than 90%) under the reaction condition that the pH value change is large. The process is easy to operate, the process is simple and the equipment demand is low; the used MS compound catalytic material is easy to regenerate and recycle. The method disclosed by the invention can be widely applied to removing newly developed pollutant in the water environment, and has wide market application prospect.

Owner:INST OF URBAN ENVIRONMENT CHINESE ACAD OF SCI

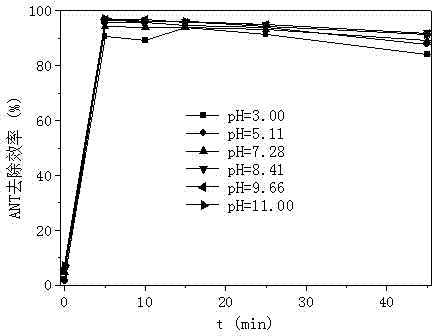

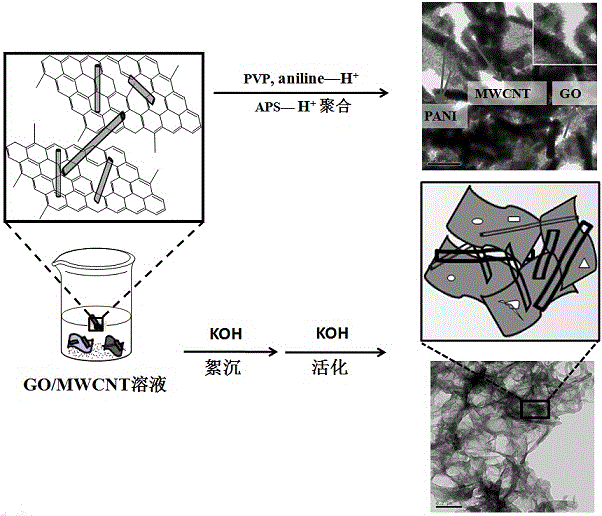

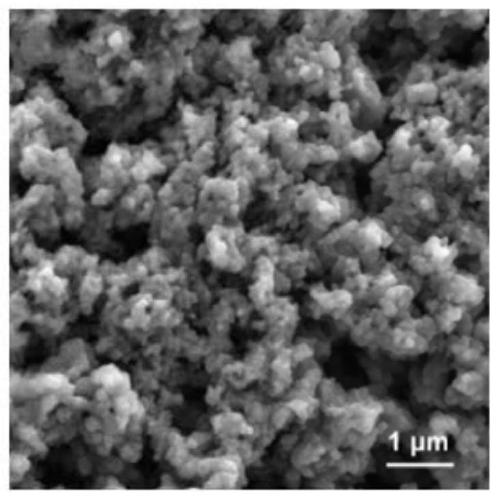

Positive/negative electrode material for high-performance asymmetric capacitor and preparation method for positive/negative electrode material

InactiveCN105609329ALarge specific surface areaImprove adsorption capacityHybrid capacitor electrodesHybrid/EDL manufacturePotassium hydroxideCarbon nanotube

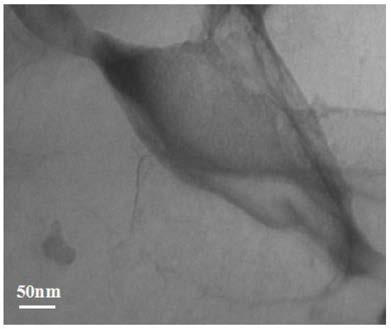

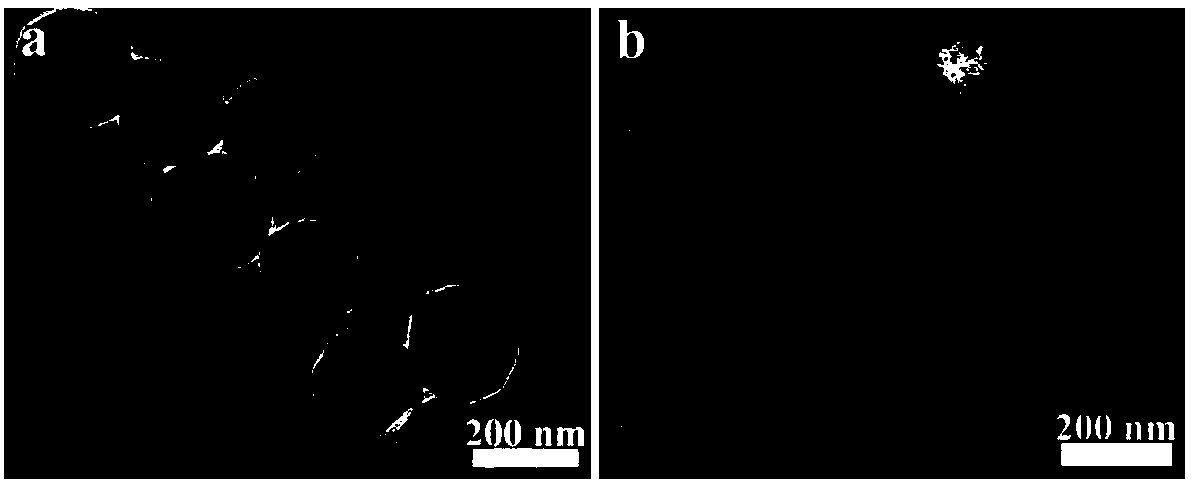

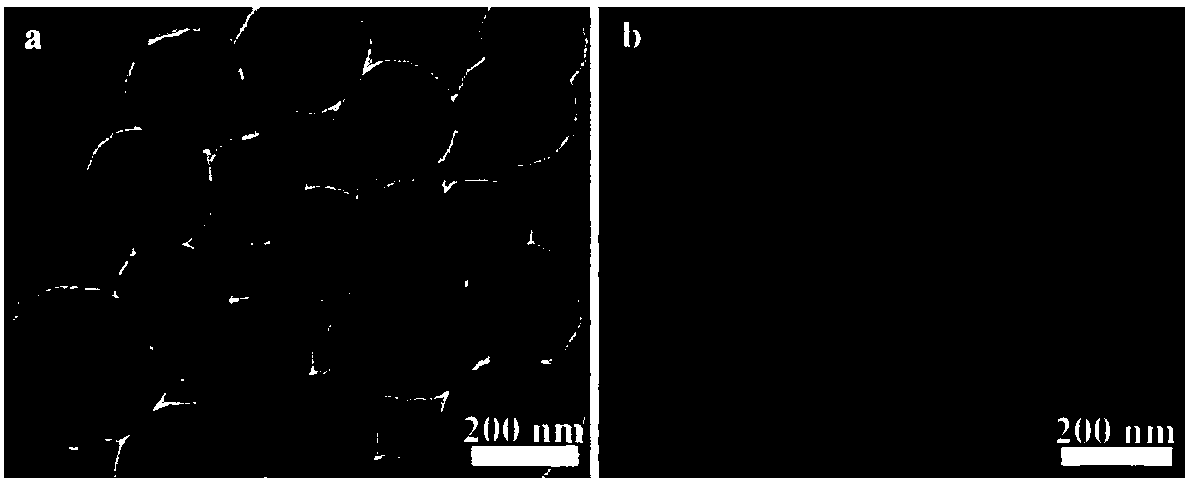

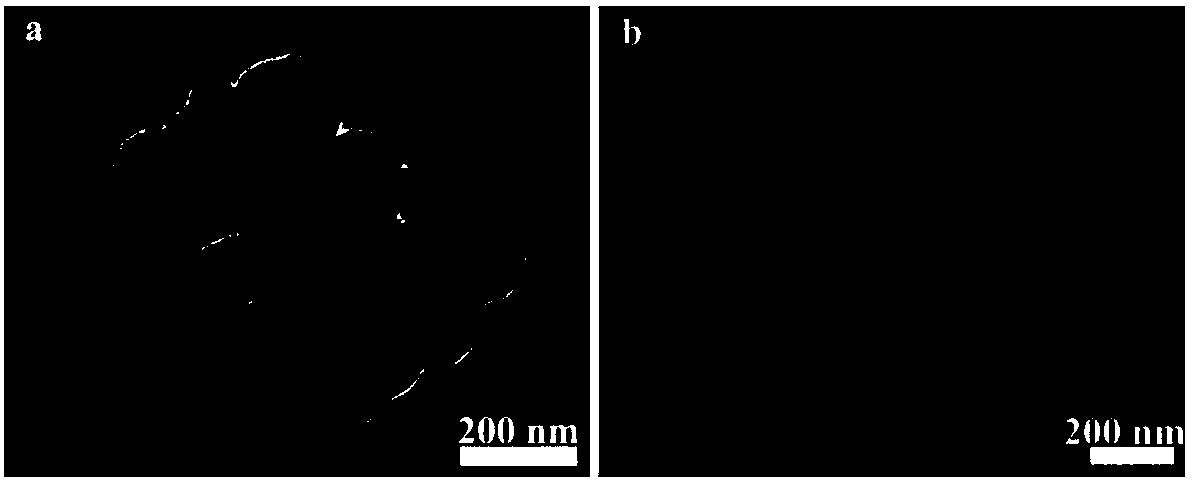

The invention relates to a positive / negative electrode material for a high-performance asymmetric capacitor. The positive electrode material is a high-specific-capacity ternary composite material: polyaniline / graphene oxide / multi-wall carbon nanotube; the negative electrode material is a potassium hydroxide activated GO / MWCNT composite material with a high specific surface area and high conductivity. An electrochemical test for the ternary positive electrode material can prove that the electrochemical performance of the ternary composite material is far better than that of a binary composite material; an electrochemical test for a simple asymmetric capacitor assembled by the negative electrode material also proves that a relatively good electrochemical performance is obtained; the preparation method is simple in process, and the raw materials are free of toxins and hazards; the microcosmic ternary structure of the obtained positive electrode material represents integrated characteristics, wherein GO provides sufficient specific surface areas and are loaded with polyaniline nanorods; the MWCNT coated with polyaniline is bridged between GO pieces; and the negative electrode material shows porous and loosening characteristics, so that the positive / negative electrode material has relatively bright application prospects in the capacitor electrode materials.

Owner:HUBEI UNIV

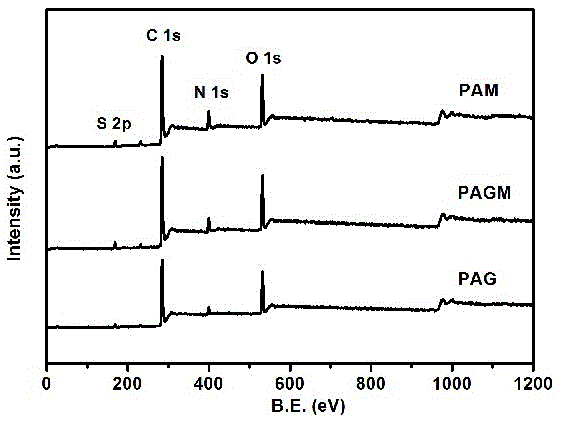

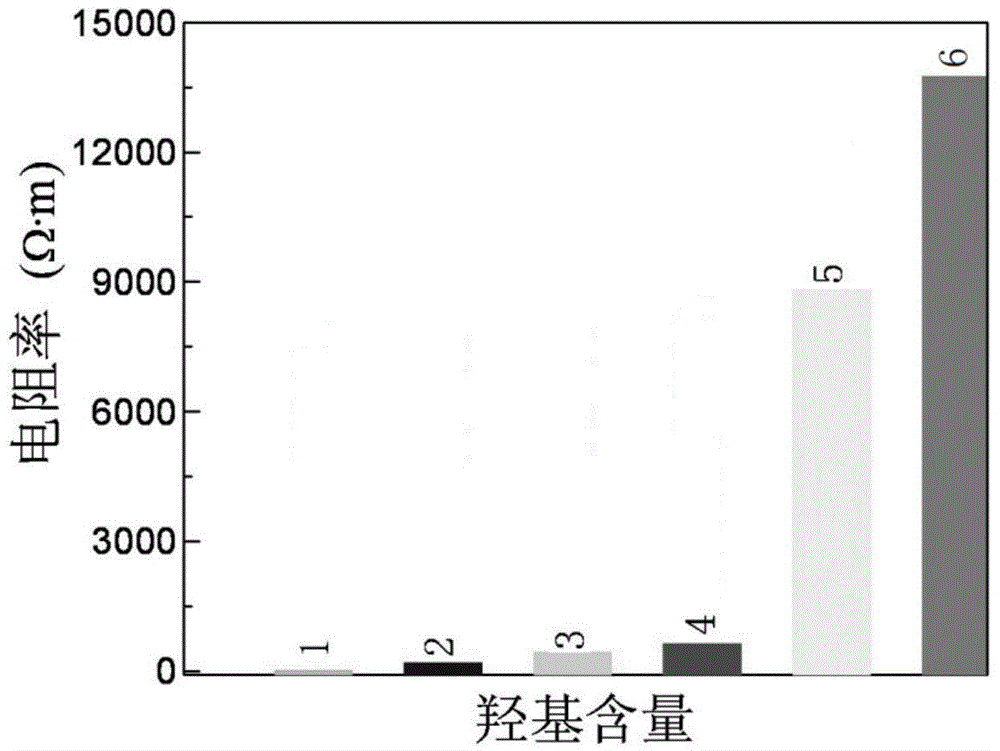

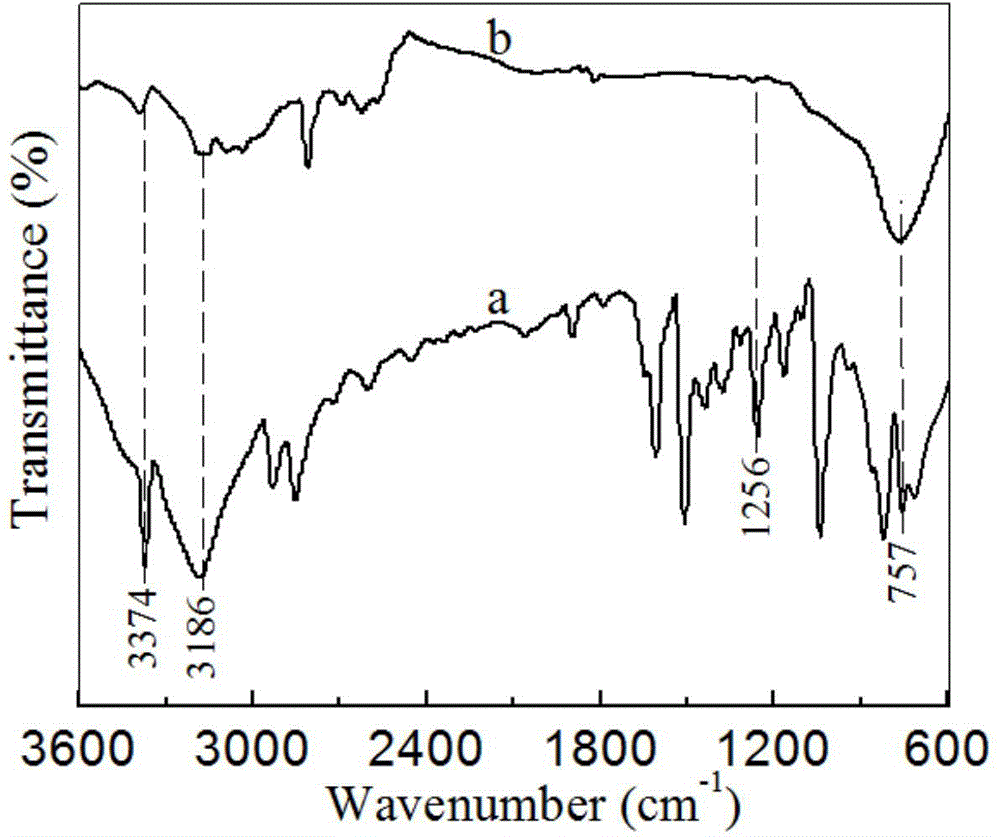

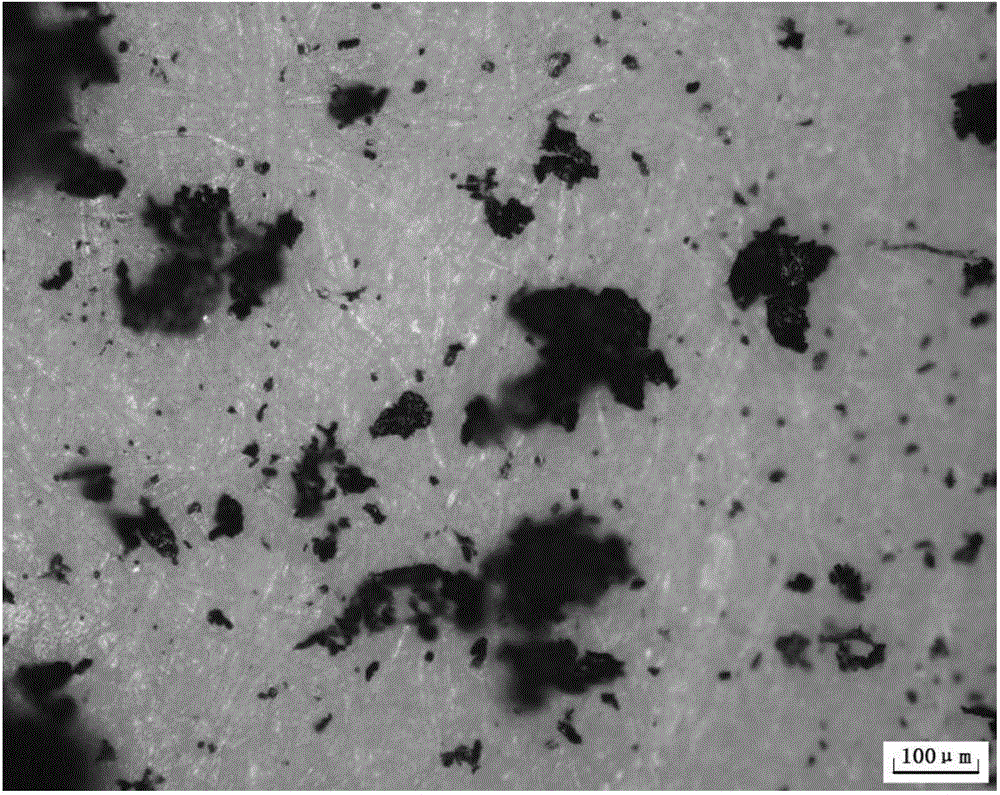

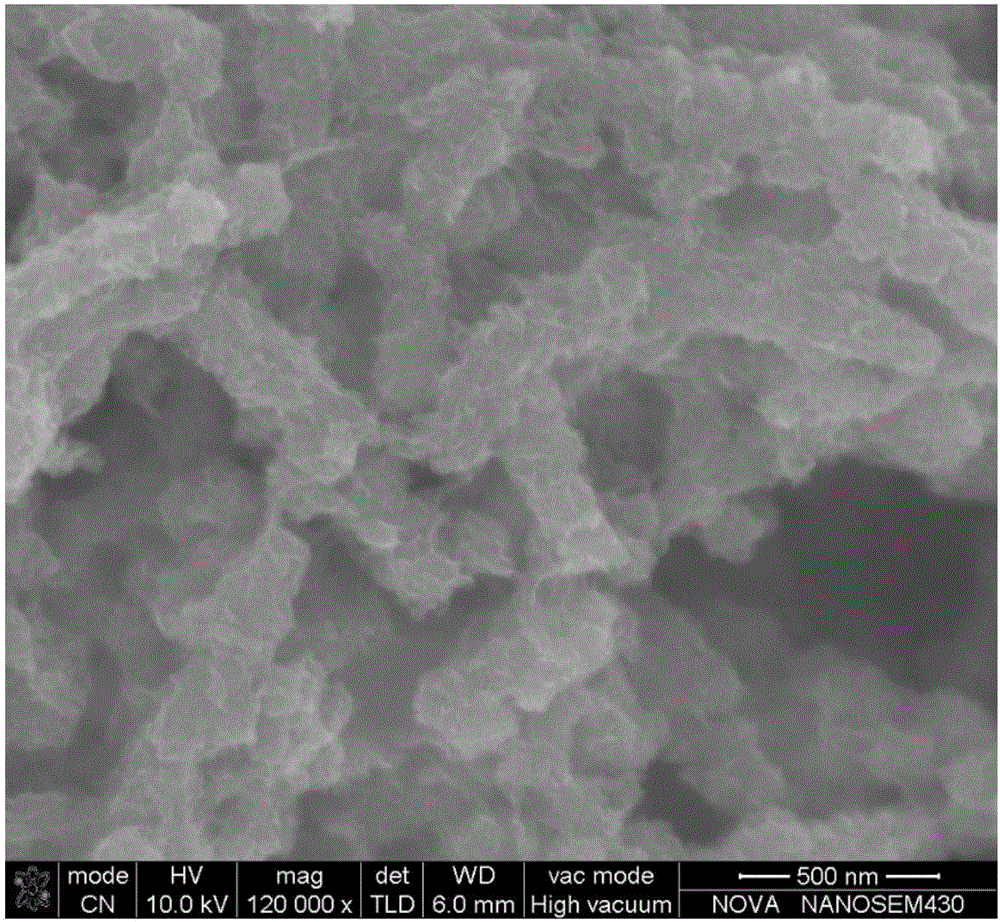

Preparation method of hydroxylated graphene powder with controllable conductive performance

The invention discloses a preparation method of hydroxylated graphene powder with a controllable conductive performance. The electrical resistivity of the powder is controlled in a range of 10<-4>ohm.m-10<5>ohm.m. The method comprises the following steps: ultrasonically treating oxidized graphene in distilled water to obtain a uniformly dispersed oxidized graphene aqueous solution; adding hydrazine hydrate and ammonium water, and condensing and refluxing in an oil bath to obtain a turbid liquid of graphene and water; then, adding amino phenyl alcohol and isoamyl nitrite and condensing and refluxing to obtain a hydroxylated graphene aqueous solution; filtering to obtain a neutral solution; and freezing and drying to obtain the hydroxylated graphene powder with the controllable conductive performance. The hydroxylation degree of graphene is controlled by controlling the rate of charge of amino phenyl alcohol and oxidized graphene so as to control the conductivity of the hydroxylated graphene powder. The hydroxylated graphene powder is safe, environmental friendly, is free of inert gas protection and foreign ions, is fluffy and is not agglomerated, is high in degree of purity, is excellent in quality and is good in solubleness.

Owner:AVIC BEIJING INST OF AERONAUTICAL MATERIALS

Prepn of nano lithium cobaltate particle

InactiveCN1526647AUniform particle sizeSolve easy reunionCobalt compoundsChemical processLithium hydroxide monohydrate

The present invention discloses preparation process of nano lithium cobaltate particle. It is one wet chemical process including dissolving monohydrate of lithium hydroxide and soluble cobalt salt, introducing organic dispersant to prevent aggregate of the primary particles, spray drying or fast solution evaporating to obtain dry powder, and heat treatment at 500-1000 deg.c to obtain 10-100 nm lithium cobaltate particle. The nano lithium cobaltate product of the present invention may be used widely in the production of lithium cell, non-water electrolyte, etc.

Owner:上海广力投资管理有限公司

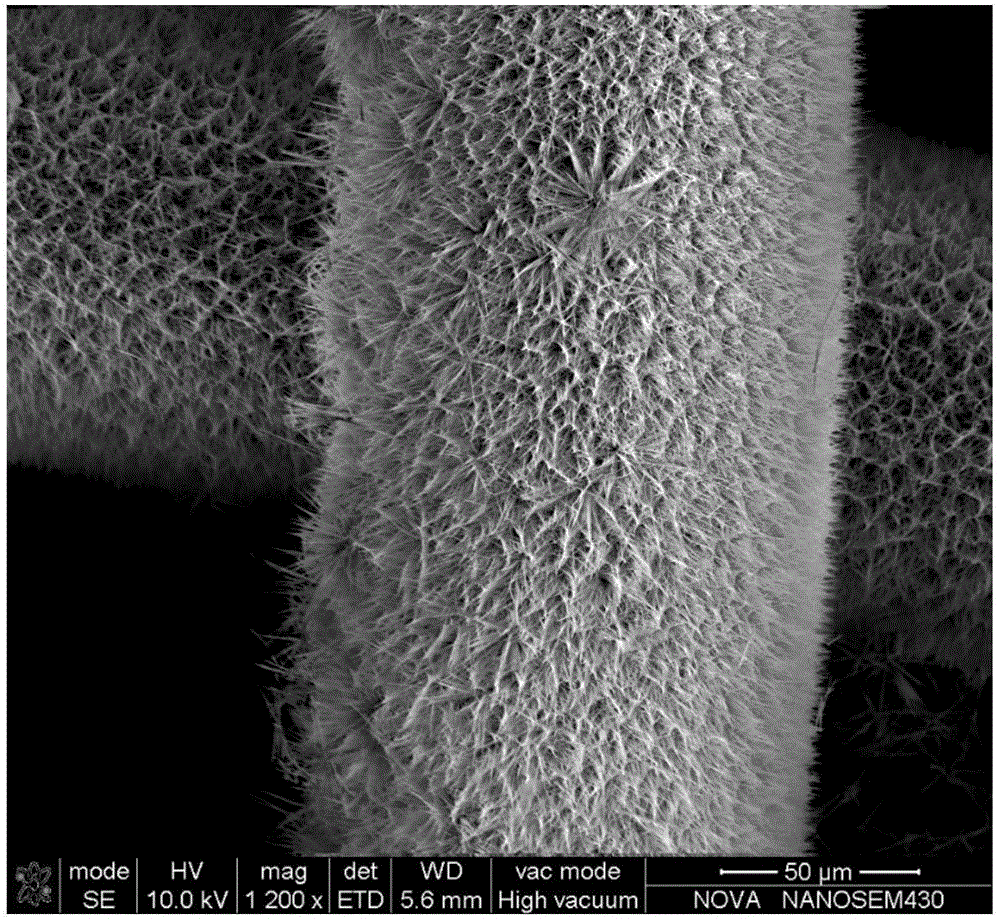

A preparing method for a hydrogen production composite catalytic electrode

InactiveCN106521460ALarge specific surface areaFully exposedLiquid/solution decomposition chemical coatingElectrodesCobaltHydrogen production

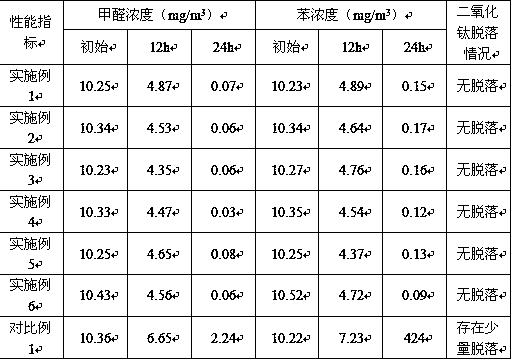

A preparing method for a hydrogen production composite catalytic electrode is disclosed. The method includes (1) cleaning metal titanium, (2) soaking the pretreated metal titanium in a weakly basic aqueous solution of a cobalt source, adding the mixture into an autoclave, performing a hydrothermal reaction at 60-120 DEG C for 2-12 h, cooling the reaction product, taking the metal titanium after cobalt functionalization out, washing the metal titanium with deionized water, and performing vacuum drying for certain hours to obtain a Co(OH)2 / Ti template, and (3) soaking the Co(OH)2 / Ti template in an aqueous solution of a sulfur source and a molybdenum source, adding the mixture into an autoclave, performing a hydrothermal reaction at 180-250 DEG C for 12-24 h, cooling the reaction product, taking the sulfurated Co(OH)2 / Ti out, washing the sulfurated Co(OH)2 / Ti with deionized water, and performing vacuum drying. According to the hydrogen production composite catalytic electrode prepared by the method, morphology of molybdenum disulfide nanosheet flowers is regular, the area of layered exposed edges is large, catalytic activity is greatly benefited, and batch production is expected.

Owner:SOUTH CHINA UNIV OF TECH

Preparation method of graphene oxide resin carbon fiber composite material

InactiveCN108623989AEnhanced interface bindingImprove the comprehensive mechanical performance indexN dimethylformamideInterlaminar shear

The invention relates to a preparation method of a graphene oxide resin carbon fiber composite material, which is applied to preparation of a heavy truck speed changer synchronizer taper ring conicalsurface friction layer FB resin carbon fiber composite material. The preparation method comprises the following steps: preparing graphene oxide from natural graphite according to a Hummers method, performing modification treatment by using N-dimethylformamide, isocyanate or derivatives thereof, and performing ultrasonic dispersion on an acetone solution and the modified graphene oxide to obtain uniformly dispersed modified graphene oxide acetone dispersing liquid; performing configuration and homogenization treatment on the dispersing liquid and FB resin adhesive, coating double sides of carbon fiber cloth with the resin adhesive containing the modified graphene uniformly, and performing solidification treatment to obtain the graphene oxide resin carbon fiber composite material. Accordingto the carbon fiber composite material prepared according to the method and under the condition of room temperature, the interlaminar shear strength is greater than 55 MPa, the tensile strength is greater than 800 MPa and the wear resistance (a friction testing machine) is less than 0.025 g / cm<2>. The production process is simple in route; the graphene oxide resin carbon fiber composite material has stable and reliable performance and is suitable for batch production.

Owner:陕西省机械研究院有限公司

Modified graphene epoxy composite anti-corrosive coating and preparation method thereof

InactiveCN112538304AEnhanced dispersion solubilitySolve easy reunionAnti-corrosive paintsEpoxy resin coatingsCorrosive substanceGraphite oxide

The invention discloses a modified graphene epoxy composite anti-corrosive coating and a preparation method thereof. The preparation method comprises the following steps of: preparing graphene oxide by adopting an improved Hummers method, then adding a modifier into the graphene oxide for functional modification, adding hydrazine hydrate in the reaction process to prepare modified graphene, and mixing the modified graphene with waterborne epoxy resin to prepare the modified graphene epoxy composite anti-corrosive coating. According to the preparation method disclosed by the invention, the graphene is modified by adopting hexamethylene diisocyanate and polyisocyanate, so that the dispersion solubility of the successfully prepared functional modified graphene in a solvent is remarkably enhanced, and the problem that the graphene is easy to agglomerate is solved; and the modified graphene is introduced into the waterborne epoxy resin, so that the uniform dispersity of the graphene in thewaterborne epoxy resin coating is improved, the interaction and compatibility between the graphene and an EP chain segment are enhanced, and the corrosion resistance of the composite coating is improved.

Owner:南京博科新材料产业研究院有限公司

Prepn of nano silver oxide particle

InactiveCN1526643AImprove stabilityNarrow particle size distributionSilve compoundsFreeze-dryingGranularity

The preparation process of nano silver oxide particle includes the following steps: dissolving silver nitrate in deionized water to compound solution of 0.2-4.0 mol / L concentration; adding organic dispersant in 1-10 wt% and dropping ammonia water in 5-15 wt% under stirring to form silver-ammonia complexing ion solution; dropping the silver-ammonia complexing ion solution into alkali solution of 0.5-3.0 mol / L concentration under stirrig to form precipitate; centrifugally separation to separate precipitate; washing with deionized water and freeze drying. The nano silver oxide particle prepared in the process of the present invention has high purity, high stability, granularity of 10-100 nm and no obvious aggregation.

Owner:上海华实纳米材料有限公司

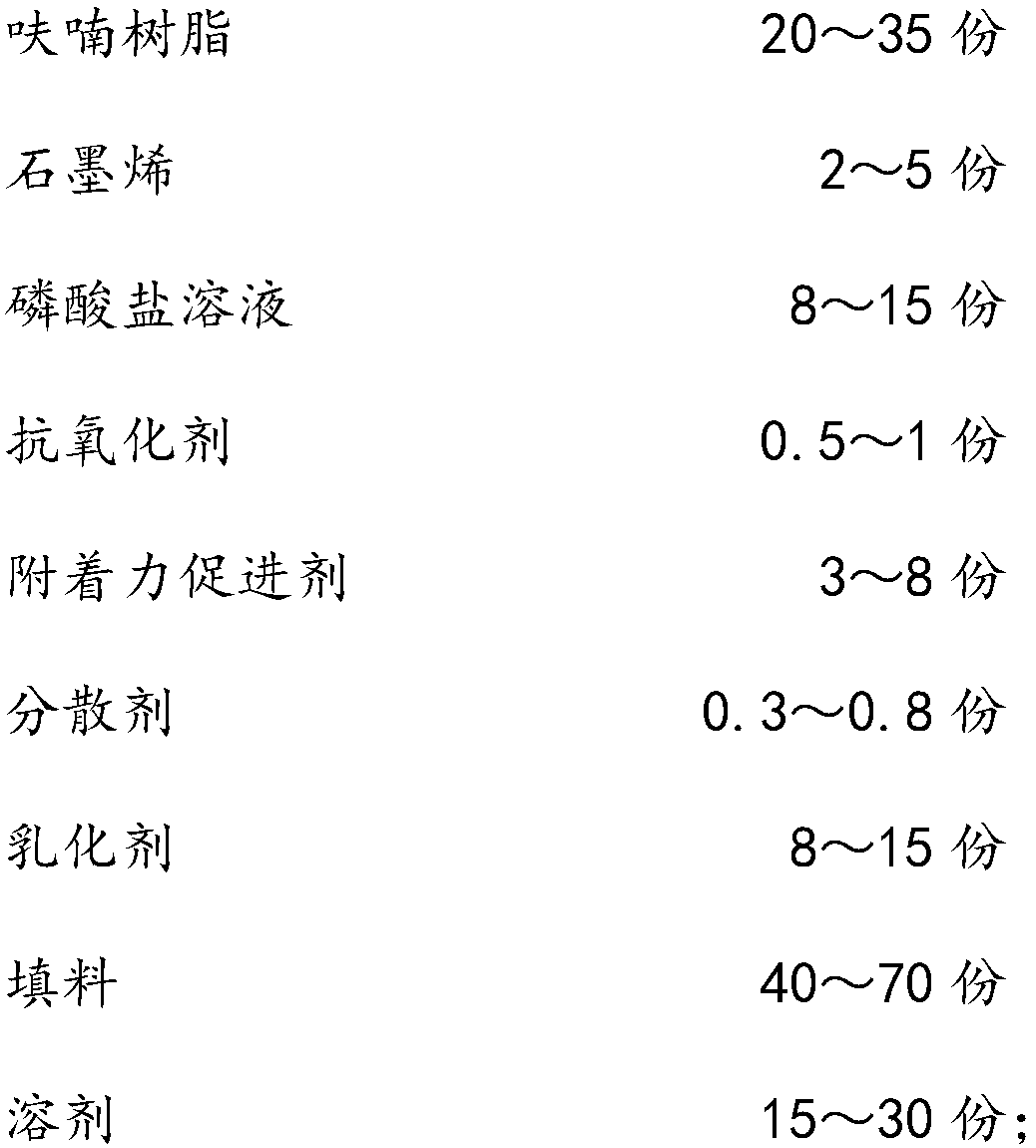

High-performance anticorrosive coating with graphene and preparation method of anticorrosive coating

ActiveCN107858066AImprove corrosion resistanceImprove antioxidant capacityAnti-corrosive paintsTO-18Antioxidant

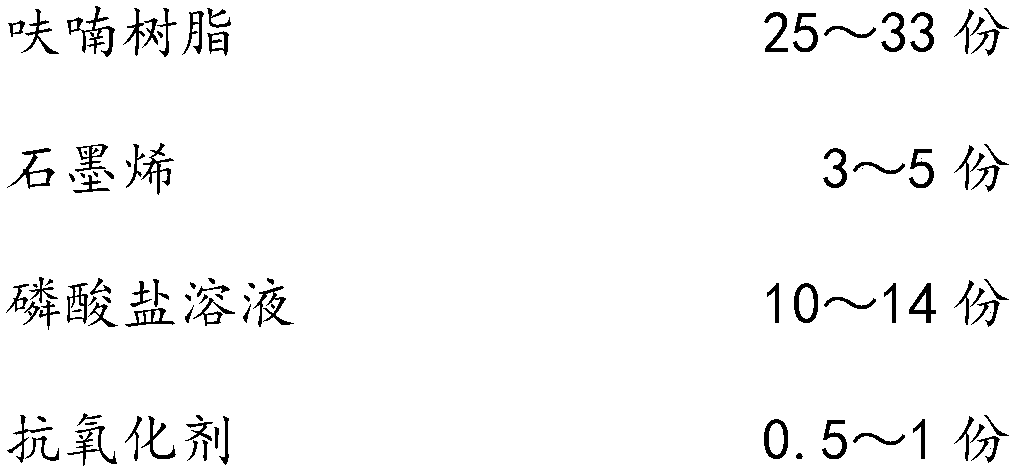

The invention provides a high-performance anticorrosive coating with graphene and a preparation method thereof. The high-performance anticorrosive coating with the graphene is prepared from a component A and a component B, wherein the component A is prepared from the following ingredients in parts by weight: 20 to 35 parts of furan resin, 2 to 5 parts of the graphene, 1 to 2 parts of phosphate solution, 0.5 to 1 part of antioxidant, 3 to 8 parts of adhesion promoter, 0.3 to 0.8 part of dispersant, 8 to 15 parts of emulsifier, 40 to 70 parts of filler and 15 to 30 parts of solvent; the component B is prepared from the following ingredients in parts by weight: 10 to 18 parts of sulfonic acid curing agent and 11 to 15 parts of methanol aqueous solution; a weight ratio of the component A to the component B is (4 to 4.5) to 1. The coating provided by the invention is used for solving the problems that a common anticorrosive coating with the furan resin is poor in oxidation-resistant performance and the graphene is easily agglomerated in the coating; the performance of the corrosion prevention, the oxidation resistance, the high temperature resistance and the like of the coating is improved and the coating has excellent comprehensive performance, is wide in scope of application and can be used for a high-temperature and high-corrosion environment.

Owner:厦门中凯新材石墨烯科技有限公司

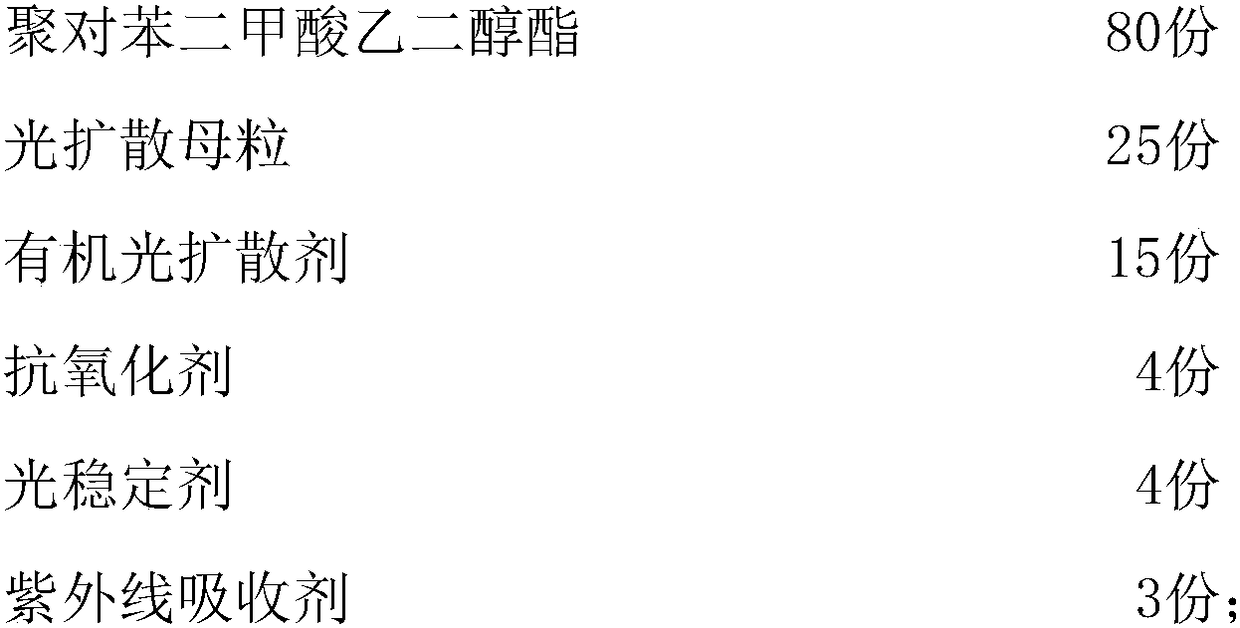

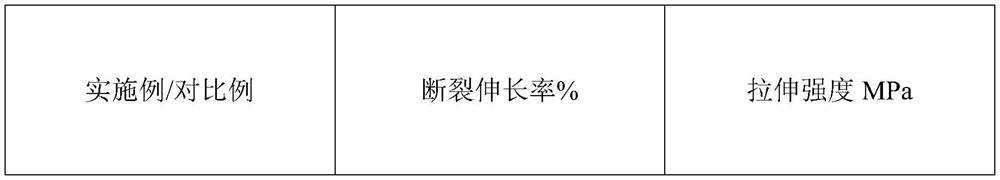

Yellowing-resisting, whitening and brightening master batch, polyester recycled material and preparation method

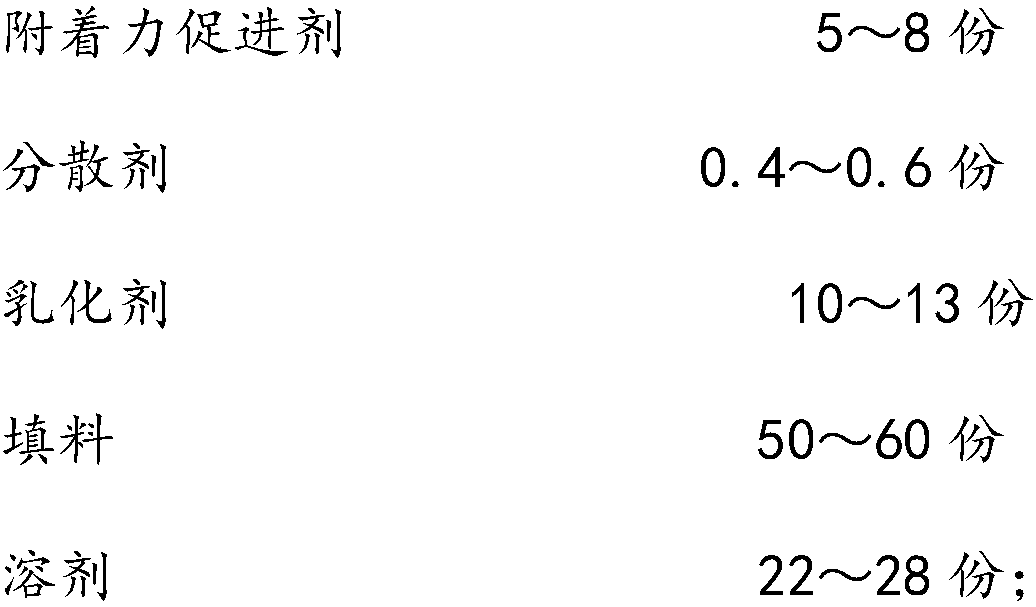

The invention relates to the technical field of polyester recycling and in particular relates to a yellowing-resisting, whitening and brightening master batch, a polyester recycled material and a preparation method. The yellowing-resisting, whitening and brightening master batch is prepared from the following raw materials in parts by weight: 40 to 60 parts of matrix resin, 12 to 20 parts of composite microspheres, 6 to 12 parts of brightening agent, 1 to 7 parts of antioxidant, 2 to 6 parts of light stabilizing agent and 3 to 7 parts of ultraviolet absorbent and the like. The yellowing-resisting, whitening and brightening master batch provided by the invention takes polyacrylonitrile which has better compatibility with polyester resin and has certain whiteness as a carrier of nano titanium dioxide and the problems that the nano titanium dioxide is easy to agglomerate and difficult to disperse and is not compatible with the matrix resin and the like are effectively solved; the nano titanium dioxide has a size effect so that the polyester recycled material has the advantages of high whiteness, high gloss and the like; furthermore, the polyacrylonitrile also can be used as reinforcing filler for reinforcing mechanical properties including tensile strength, impact resistance and the like of the master batch.

Owner:DONGGUAN JISHUO IND CO LTD

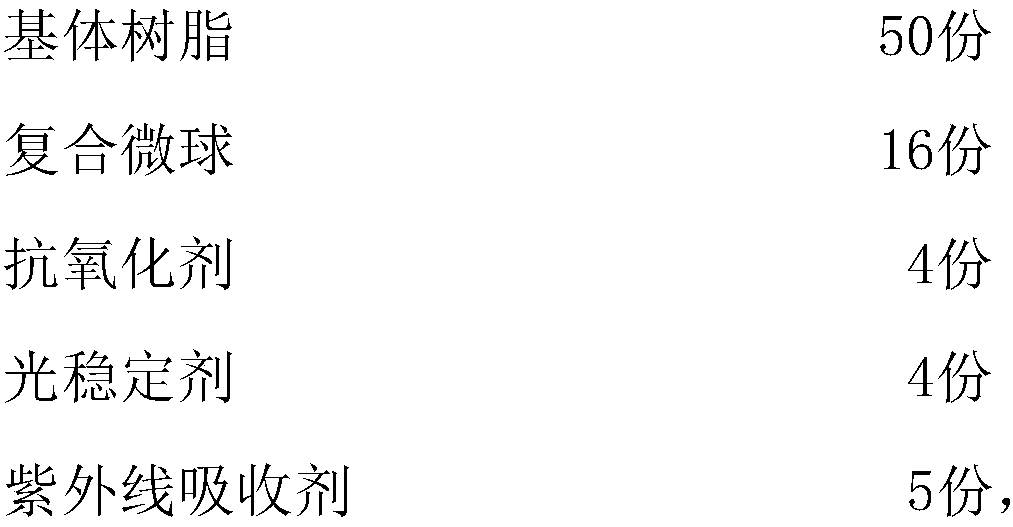

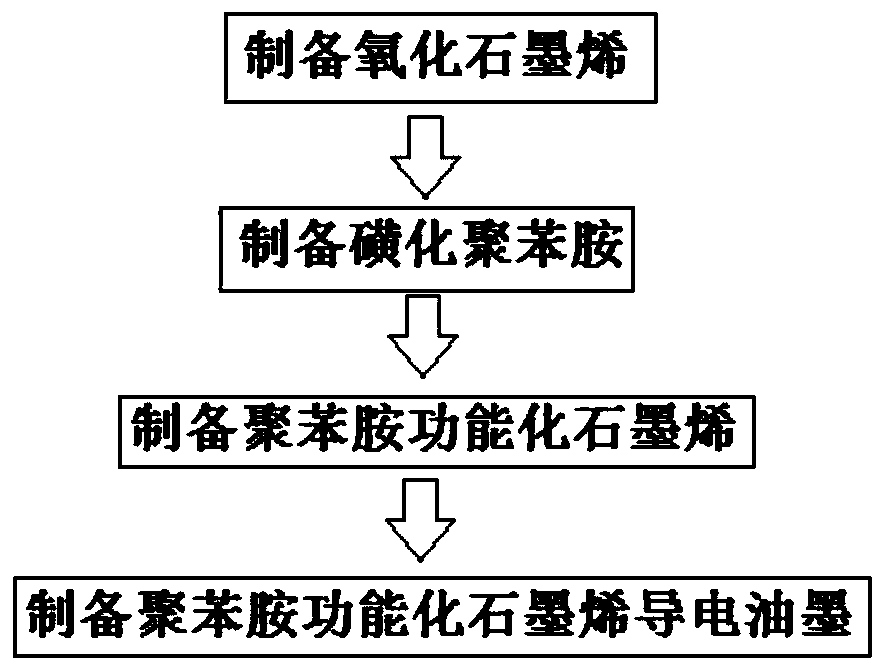

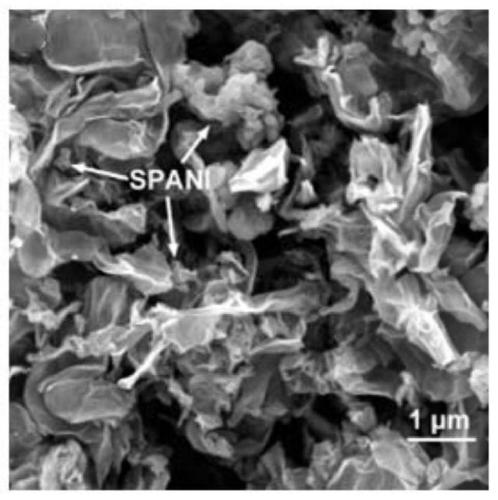

Polyaniline functionalized graphene conductive ink and preparation method thereof

The invention discloses polyaniline functionalized graphene conductive ink and a preparation method thereof, wherein a polyaniline functionalized graphene material is prepared by carrying out ultrasonic treatment on sulfonated polyaniline and graphene oxide dispersion liquid and then carrying out in-situ reduction; according to the preparation method, a graphene composite material which can be stably dispersed in water is obtained by utilizing pi-pi interaction between polyaniline and graphene and sulfonic acid groups on polyaniline, so that the problem that a graphene lamellar structure is easy to agglomerate is solved. According to the conductive ink, polyaniline functionalized graphene and conductive carbon black are used as conductive fillers, water-based resin is used as a binder, anda mixture of water and low-carbon alcohol is used as a solvent to form a point-surface contact conductive network, so that the conductivity of the conductive ink is improved, and the conductive ink is green, environment-friendly and friendly to environment. Furthermore, after the conductive ink is formed into a film, a conductive film with high conductivity, uniform film formation and strong bending resistance can be obtained, the conductivity is as high as 6.61 S / cm, and the conductive ink is expected to be applied to the field of flexible electronic circuit printing.

Owner:GUANGZHOU SPECIAL PRESSURE EQUIP INSPECTION & RES INST

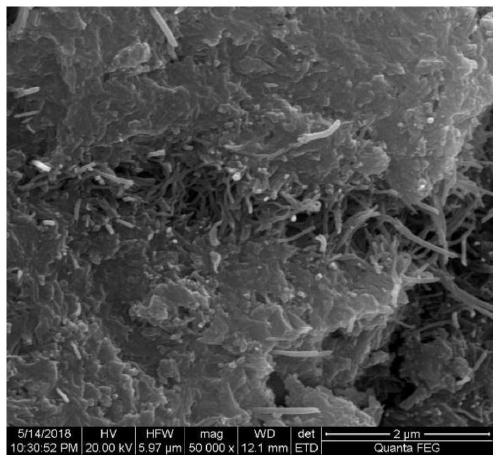

Method for adding mesoscopic-scale three-dimensional strengthening phase into metal

InactiveCN109112334AGood toughening effectWon't reuniteAdditive manufacturing apparatusTransportation and packagingGraphiteMethane gas

The invention provides a method for adding a mesoscopic-scale three-dimensional strengthening phase into metal. The method comprises the following steps: firstly, putting metal based alloy powder intoa plasma chemical vapor deposition vacuum device; introducing methane gas, and adjusting methane gas flow, pressure of the vacuum device, radio frequency power, heating temperature and deposition time to obtain graphite sheet / metal-based composite material powder with an in-situ grown three-dimensional graphite sheet; then carrying out compacting formation on the graphite sheet / metal-based composite material powder; finally, carrying out thermal treatment to prepare a graphite sheet / metal-based composite material. By adopting the method provided by the invention, the graphite sheet with a three-dimensional mesoscopic scale is uniformly dispersed in a metal matrix under the condition that the graphite sheet and the metal matrix have a good binding force, so that the problems that the graphite sheet is difficult to disperse uniformly in the metal matrix and the binding force is poor are solved and the aim of strengthening and toughening metal through the graphite sheet is realized. Themethod is used for preparing the three-dimensional mesoscopic-scale graphite sheet strengthened metal-based composite material, has a simple and efficient technology and is suitable for industrial production.

Owner:AVIC BEIJING INST OF AERONAUTICAL MATERIALS

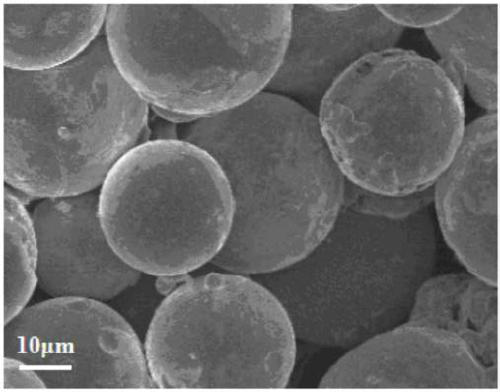

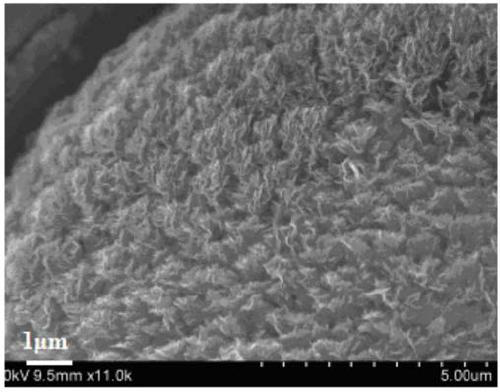

Ni/CeO2NP@PANI core-shell structural composite material and preparation method thereof

The invention discloses a Ni / CeO2NP@PANI core-shell structural composite material and a preparation method thereof. The method comprises the following steps: firstly, Ni / CeO2 NPs are prepared througha hydrothermal method; and then aniline is polymerized on the surfaces of the Ni / CeO2 NPs by adopting a chemical oxidation polymerization method, and in the polymerization process of the aniline, through changing a concentration of HCl, conversion from a Ni / CeO2NP@PANI core-shell structure to a spaced Ni / CeO2NP@PANI core-shell structure to PANI hollow spheres is realized. In the process, templatesare not needed, the method is green and environmentally friendly, the preparation method is simple, the preparation process is safe, the energy consumption is low, and the operability is strong; andthe Ni / CeO2 NPs prepared by the method have rough surfaces, so that the specific surface area can be increased to increase the contact area of the Ni / CeO2 NPs and the PANI, and the diffusion of ions and electrons can be promoted to effectively improve the electrochemical performance.

Owner:QILU UNIV OF TECH

High brightness liquid crystal display module

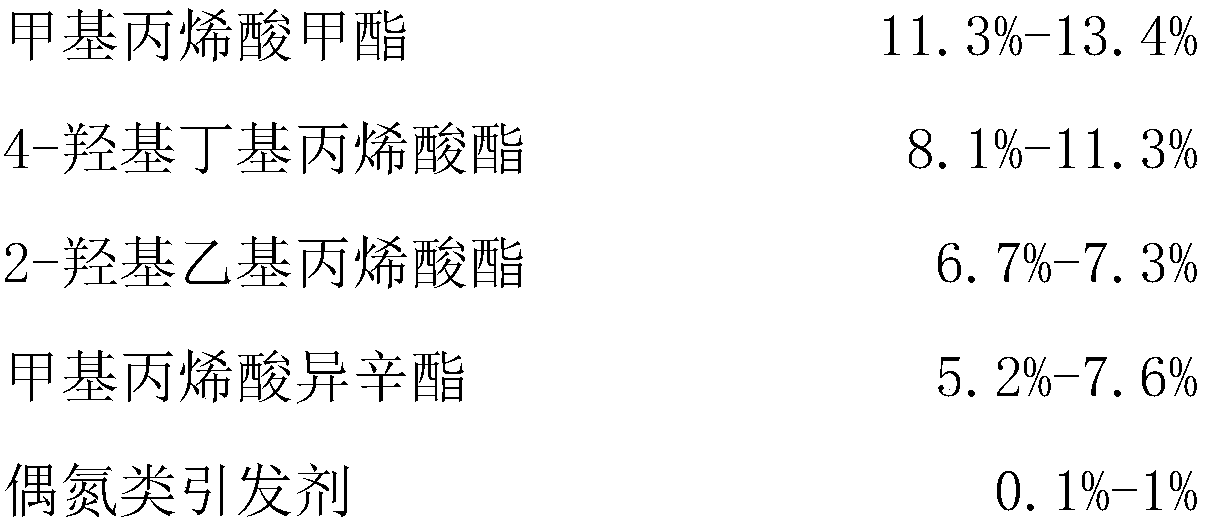

InactiveCN108319060ASolve easy reunionHigh refractive indexOrganic non-macromolecular adhesiveNon-linear opticsPrepolymerPhotoinitiator

The invention relates to the technical field of liquid crystal displays, in particular to a high brightness liquid crystal display module. The high brightness liquid crystal display module comprises abacklight module and a liquid crystal module, a brightening structure layer is arranged in the liquid crystal module, the brightening module is composed of a plurality of microprism bars, the brightening structure layer is formed by the solidification of a UV optical adhesive, and the UV optical adhesive is formed by acrylic acid prepolymer, photocurable monomer, photoinitiator, brightening masterbatch and light stabilizer. Polyimide microspheres with better compatibility are taken as the carrier of high-refractive nano particles to effectively solve the problems of easy aggregation, difficult dispersing, substrate resin incompatibility and the like of the high-refractive nano particles, the refractivity of the UV optical adhesive is greatly improved, and then the prism structure of the brightening structure layer is utilized to concentrate light, so that the liquid crystal display module has the advantage of high brightness; polyimide can also be adopted as a blending modification material to achieve the complementation with the mechanical performance of acrylic acid resin.

Owner:JIANGXI PINGBO ELECTRONICS

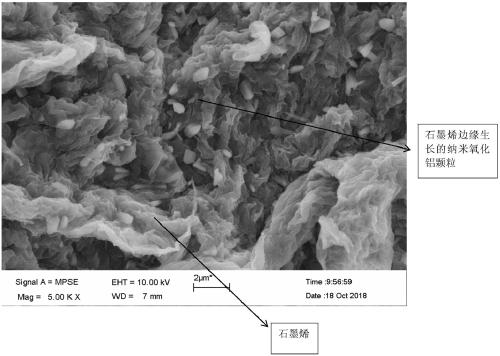

Graphene composite material, graphene aluminum oxide composite material and preparation method and application of graphene aluminum oxide composite powder material

InactiveCN109650386ANot easy to reuniteImprove performanceCarbon compoundsMaterials preparationAluminum Ion

The invention relates to the field of material preparation, in particular to a graphene composite material, a graphene aluminum oxide composite material and a preparation method and application of a graphene aluminum oxide composite powder material. The method comprises the following steps that aluminum ions are slowly released from an aluminum salt complex in an alkaline environment, and a graphene oxide material is added. By placing the aluminum salt complex in an alkaline environment, aluminum ions originally immobilized in the complex can be slowly released, thereby providing favorable guarantee for the subsequent preparation of the graphene composite material with good performance. The graphene aluminum oxide composite powder material is not easy to agglomerate, so that when the graphene aluminum oxide composite powder material is applied to the preparation of ceramic composite materials, metal composite materials and polymer composite materials, the graphene aluminum oxide composite powder material is not easy to agglomerate so as to prepare the ceramic composite materials, the metal composite materials and the polymer composite materials with good performance, thereby effectively solving the problem that graphene oxide materials are easy to agglomerate in the prior art.

Owner:NANKAI UNIV +1

Jade-like composite and preparation method thereof

The invention relates to the technical field of resin composites, in particular to a jade-like composite and a preparation method thereof. The jade-like composite comprises matrix resin, light diffusion microspheres, antioxidant, light stabilizer, ultraviolet light absorber, toner and the like. The composite disclosed by the invention presents an evenly dispersed natural jade appearance, and in addition, nanometer inorganic light diffusant enables the jade-like composite to own the advantages of high haze, high refractive index and the like due to the size effect of the nanometer inorganic light diffusant. In addition, the jade-like composite can serve as the interlayer of double-layer glass, so that the jade effect has third dimension, the jade composite can be favorably protected, and the possibility of the physical damage or the chemical oxidization of the jade composite is reduced.

Owner:DONGGUAN JISHUO IND CO LTD

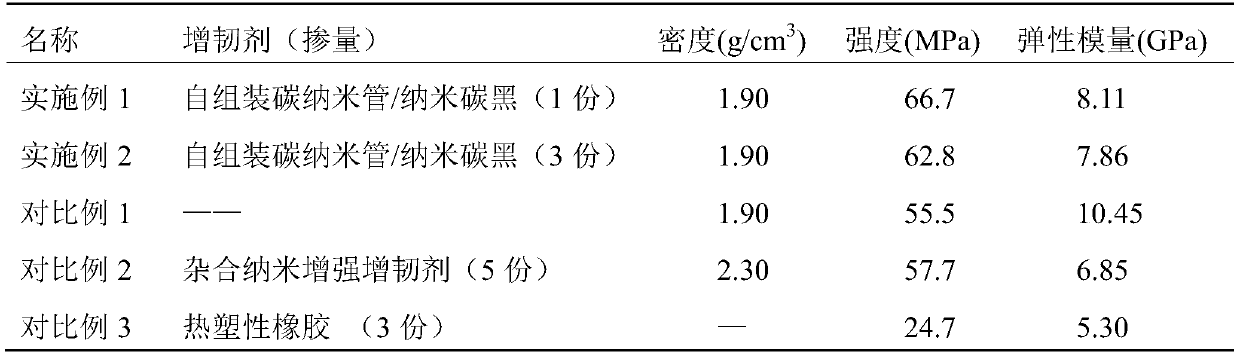

Nano composite toughened oil well cement and preparation method and application thereof

ActiveCN109897616ALow elastic modulusIncrease ultimate compressive strengthDrilling compositionSealing/packingCarbon nanotubeMaterials science

The invention discloses nano composite toughened oil well cement and a preparation method and application thereof. The nano composite toughened oil well cement is characterized by being prepared from,by weight, 100 parts of cement, 0.5-5 parts of self-assembled carbon nanotube / nano carbon black, 0.1-1.0 part of a dispersing agent, 0.2-0.9 part of a retarder, 0-2 parts of a fluid loss agent, 0-0.5part of an antifoaming agent and 40-60 parts of water. The self-assembled carbon nanotube / nano carbon black is prepared from an electrostatic self-assembly process and is in a grape bunch structure.Under low doping of self-assembled carbon nanotube / nano carbon black, oil well cement slurry which is high in stability, free of sedimentation, high in rheological property, adjustable in thickening time and low in water loss can be prepared according to a traditional process, hardened oil well set cement has excellent characteristics including low elasticity modulus and high ultimate compressivestrength, the problem that an oil well cement sheath is prone to cracking in a unconventional complex load environment can be solved, long-term cementing integrality in well cementation is guaranteed,the service life of an oil-gas well is prolonged, and the recovery ratio is increased.

Owner:DALIAN UNIV OF TECH

Cellulose hybrid filler reinforced polymer composite material and preparation method thereof

The invention discloses a cellulose hybrid filler reinforced polymer composite material and a preparation method thereof. The material comprises the following raw materials: 100 parts of polymer matrix; 5 parts of compatilizers; and 1-40 parts of engineered stone waste / agricultural and forestry waste hybrid fillers. The preparation method includes the following steps: (1) blending the engineered stone waste and the agricultural and forestry waste, and adding water to prepare an aqueous dispersion; (2) grinding the aqueous dispersion to prepare a micro-nano hybrid filler dispersion; (3) performing suction filtration on the micro-nano hybrid filler solution, drying, and mechanically crushing to obtain micro-nano hybrid filler powder; (4) blending the micro-nano hybrid filler powder with thepolymer and the compatilizers, and stirring; and (5) extruding and granulating the mixture through a machine, and performing injection molding through an injection molding machine to obtain a corresponding product. The method has the advantages of reasonably and effectively realizing high-value utilization, avoiding environmental pollution, effectively solving the problem that cellulose is easy toagglomerate in non-polar polymer, and endowing polymer composite materials with excellent mechanical properties.

Owner:SICHUAN UNIV

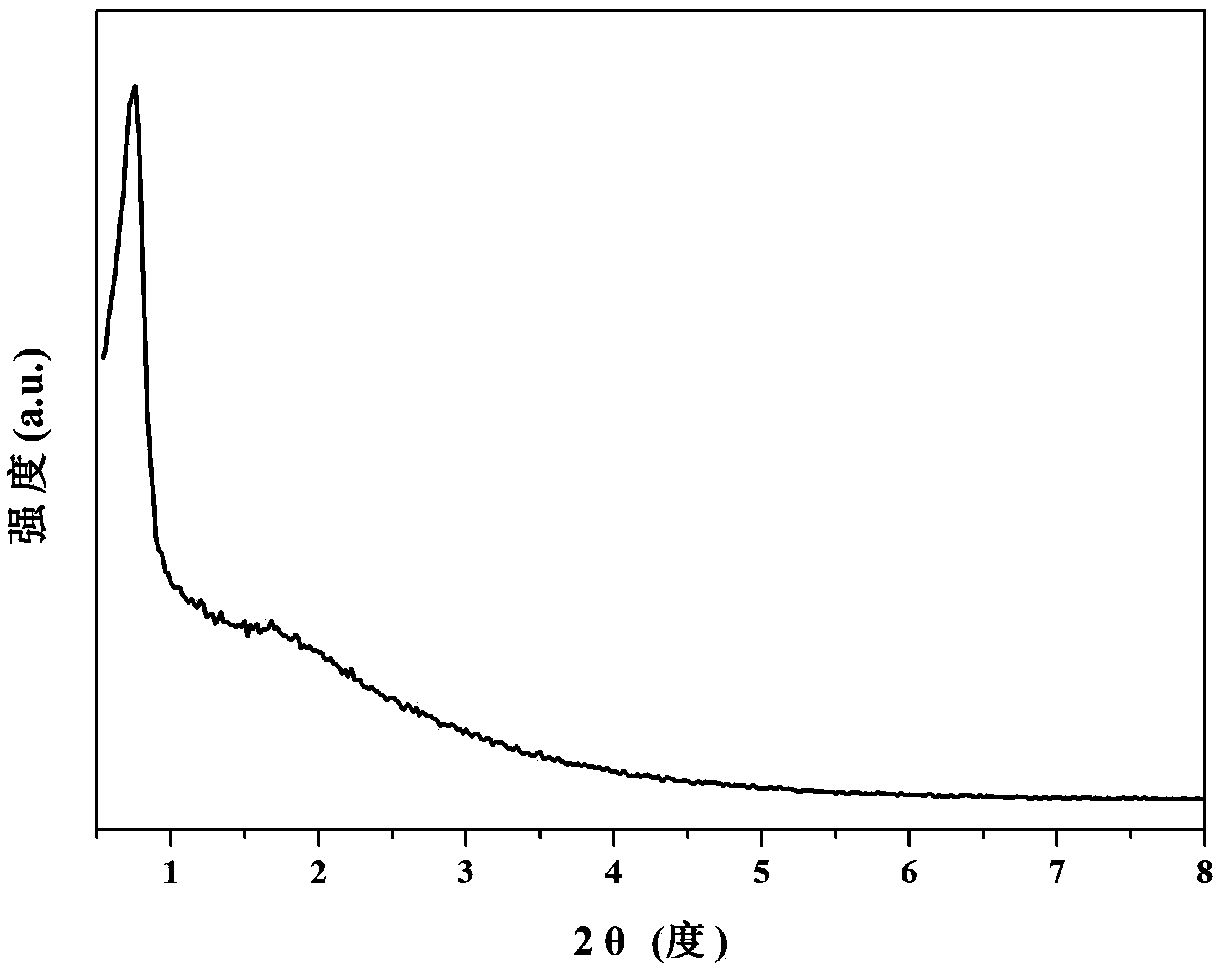

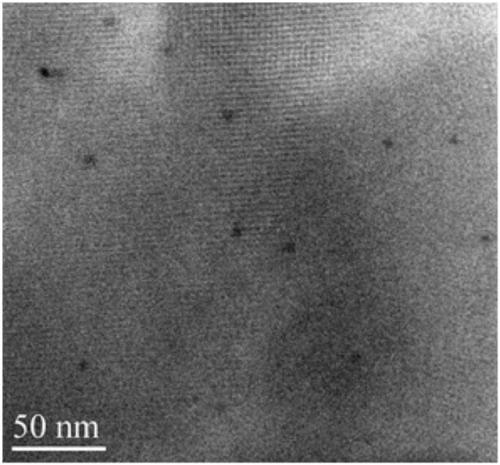

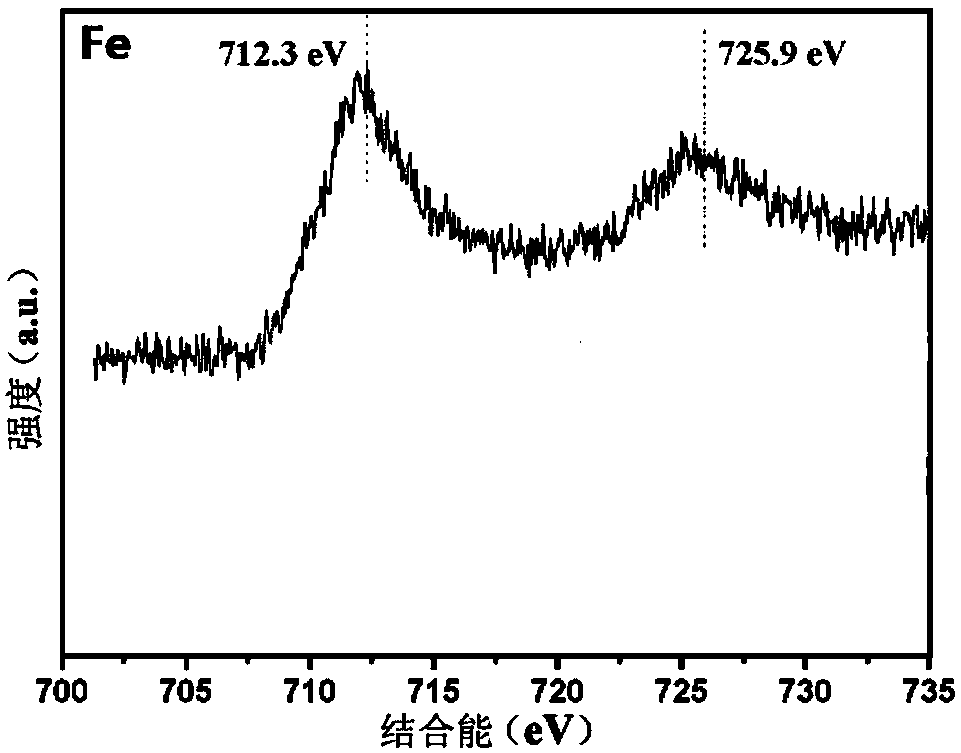

Nano-iron modified SBA-16 molecular sieve and preparation method and application thereof

ActiveCN109485060AImprove conversion rateHigh selectivityOrganic chemistryMolecular sieve catalystsMolecular sieveAfter treatment

The invention relates to a nano-iron modified SBA-16 molecular sieve, and further relates to a preparation method thereof. Nano-iron, in a simple substance form, is embedded in a framework of the molecular sieve; the preparation method includes the steps of S1, mixing a silicon source, water, an organic template, an iron-source complex, acid and alcohol to obtain a reaction mixture; S2, subjectingthe reaction mixture to hydrothermal crystallization, and performing after-treatment, to obtain a Fe-SBA-16 molecular sieve; S3, subjecting the Fe-SBA-16 molecular sieve to reduction treatment through hydrogen to obtain the nano-iron modified SBA-16 molecular sieve. The nano-iron modified SBA-16 molecular sieve still has cubic mesoporous channel structure and high specific surface area, and granularity of nano-iron in the framework ranges from 3nm to 4nm.

Owner:CHINA PETROLEUM & CHEM CORP +1

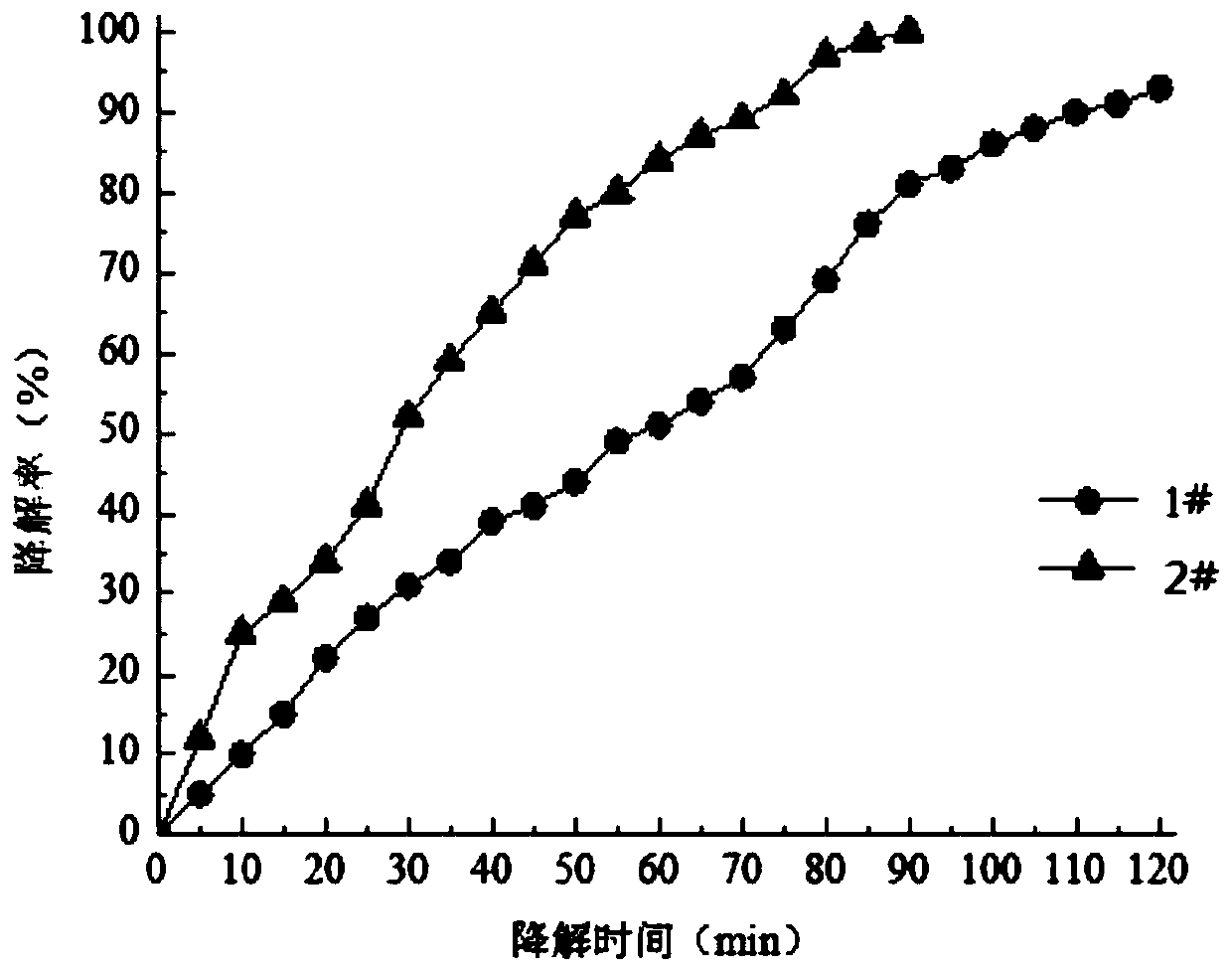

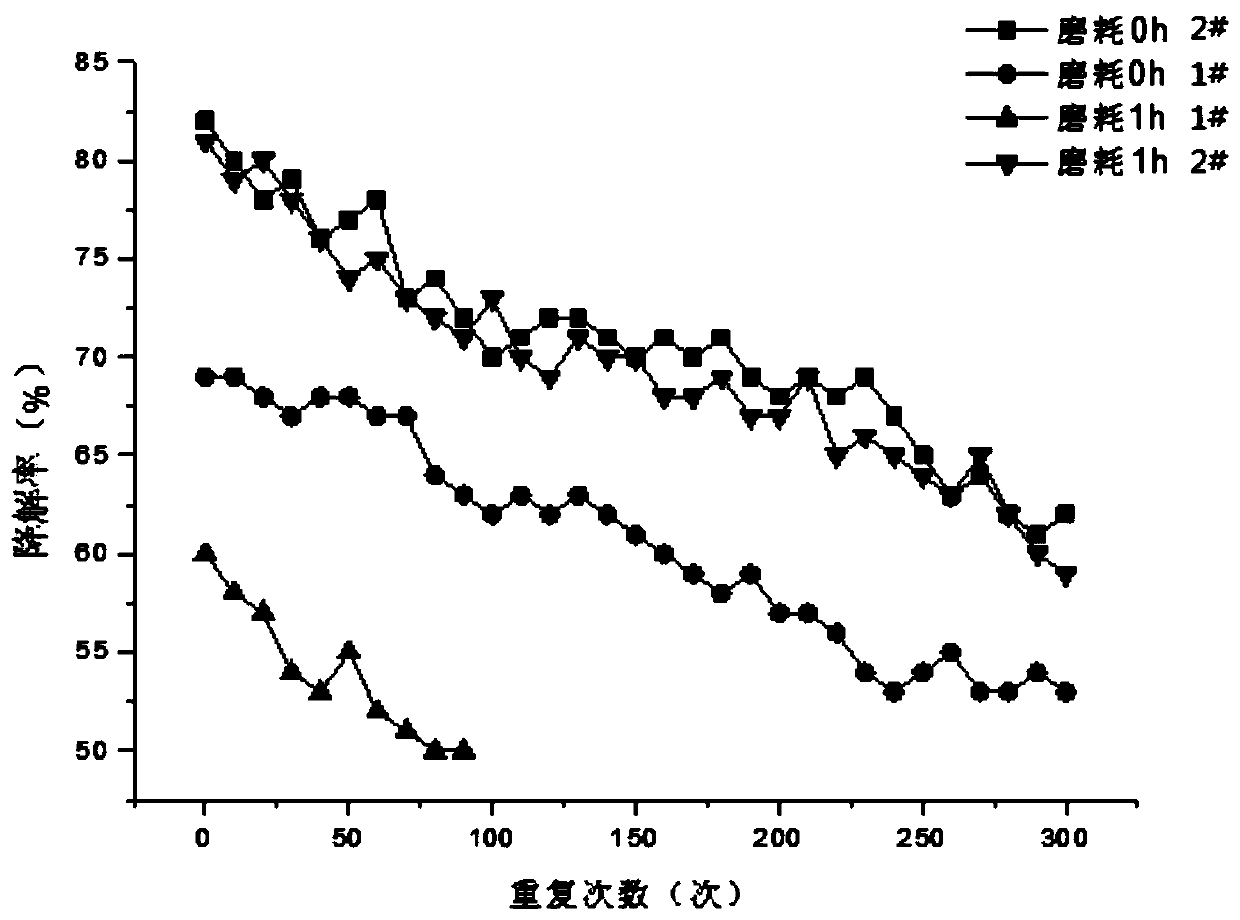

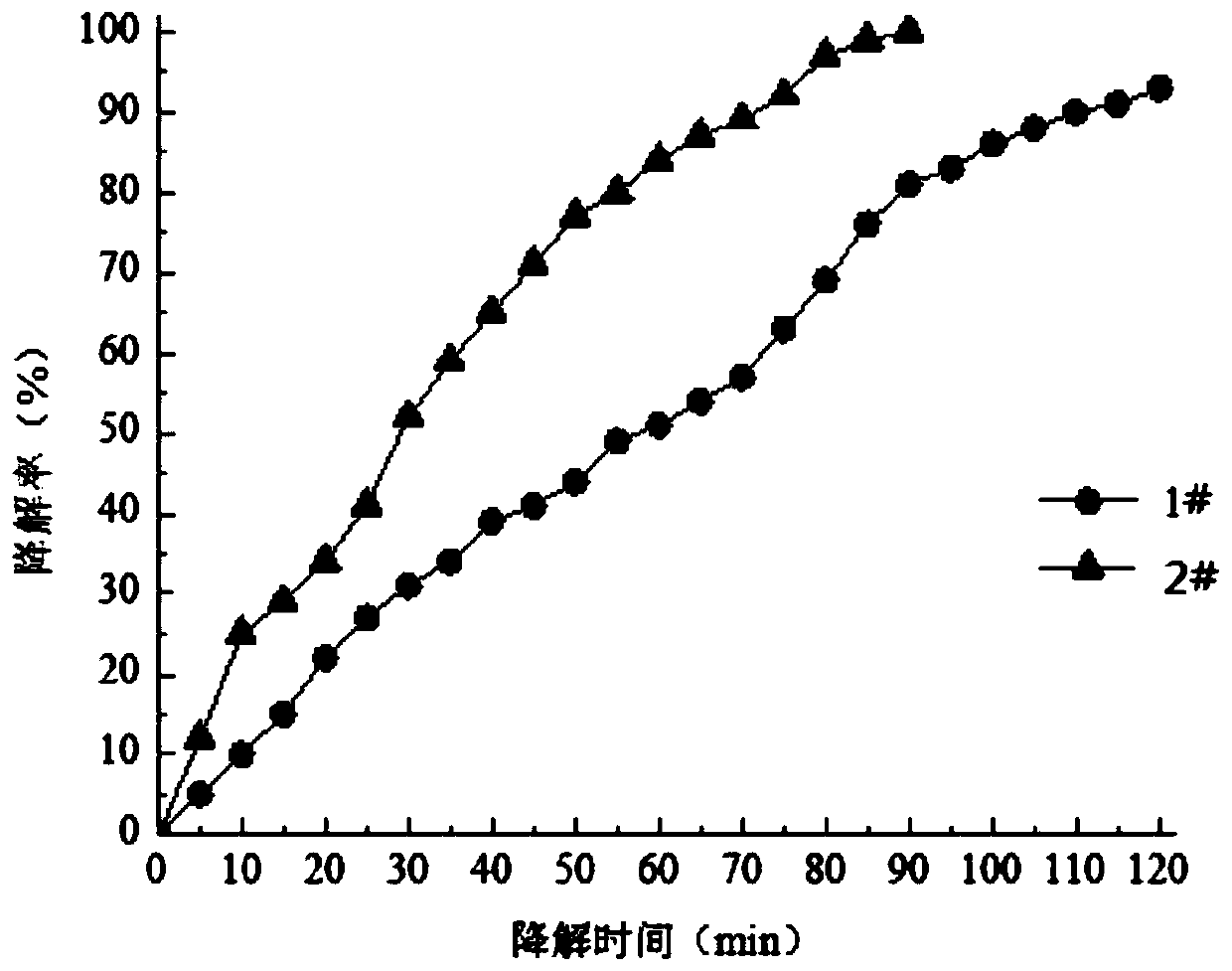

High-efficiency and durable exhaust gas degradation material and preparation method thereof

InactiveCN110003725AImprove abrasion resistanceExtended missionUnspecified rubber coatingsExhaust gasNano tio2

The invention belongs to the technical field of automobile exhaust gas treatment, and particularly discloses a high-efficiency and durable exhaust gas degradation material and a preparation method thereof. The high-efficiency and durable exhaust gas degradation material is prepared from, by mass, 40%-45% of nano TiO2, 43%-48% of Al2O3 and 8%-12% of rubber powder. The exhaust gas degradation material is composed of the nano TiO2, the Al2O3 and the rubber powder, wherein the addition of the Al2O3 and rubber powder modifies the nano TiO2, compared with a pure nano TiO2 material, the material is prepared into a coating, the coating is applied on the road surface, the material has a faster and higher exhaust gas degradation rate and better wear resistance, thereby making the nano TiO2 be betterapplied and popularized in the field of automobile exhaust gas degradation.

Owner:CHINA MERCHANTS CHONGQING COMM RES & DESIGN INST

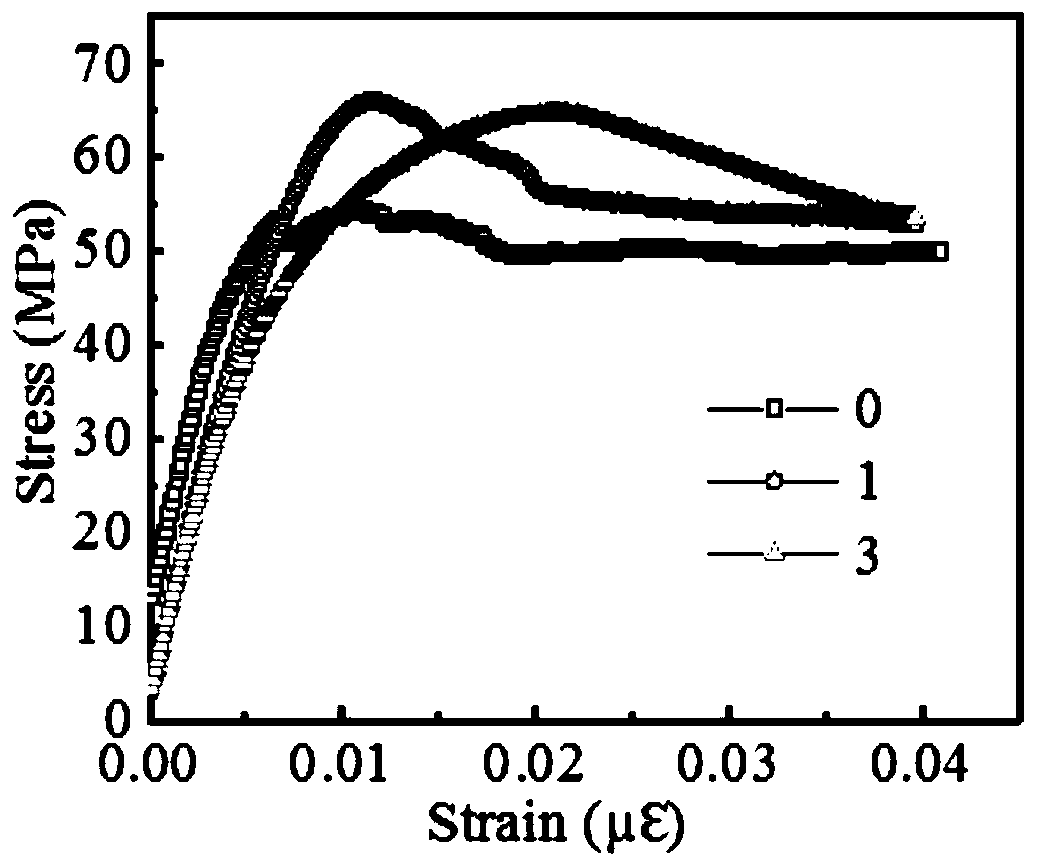

Method for strengthening and toughening akermanite bone scaffold through cooperation of graphene and BNNT

InactiveCN107029283AAccelerate mutual dispersionSolve easy reunionProsthesisBoron nitride nanotubeMagnesium

The invention provides a method for promoting uniform dispersion of graphene and boron nitride nanotubes (BNNT) in a basal body and strengthening and toughening an akermanite bone scaffold through cooperation of graphene and BNNT. The method has the advantages that a three-dimensional nanometer second phase is formed through combination of two-dimensional graphene and one-dimensional BNNT, mutual dispersion is promoted through synergetic support, and the problem of agglomeration when graphene or BNNT is independently used is solved; by means of the excellent mechanical property and the large specific surface areas of graphene and BNNT, the strength and the toughness of the akermanite bone scaffold are improved through pull-out effect and crack deflection; due to the fact that graphene and BNNT can induce osteogenic differentiation of stem cells, the osteogenic capability of the akermanite bone scaffold is further improved.

Owner:CENT SOUTH UNIV

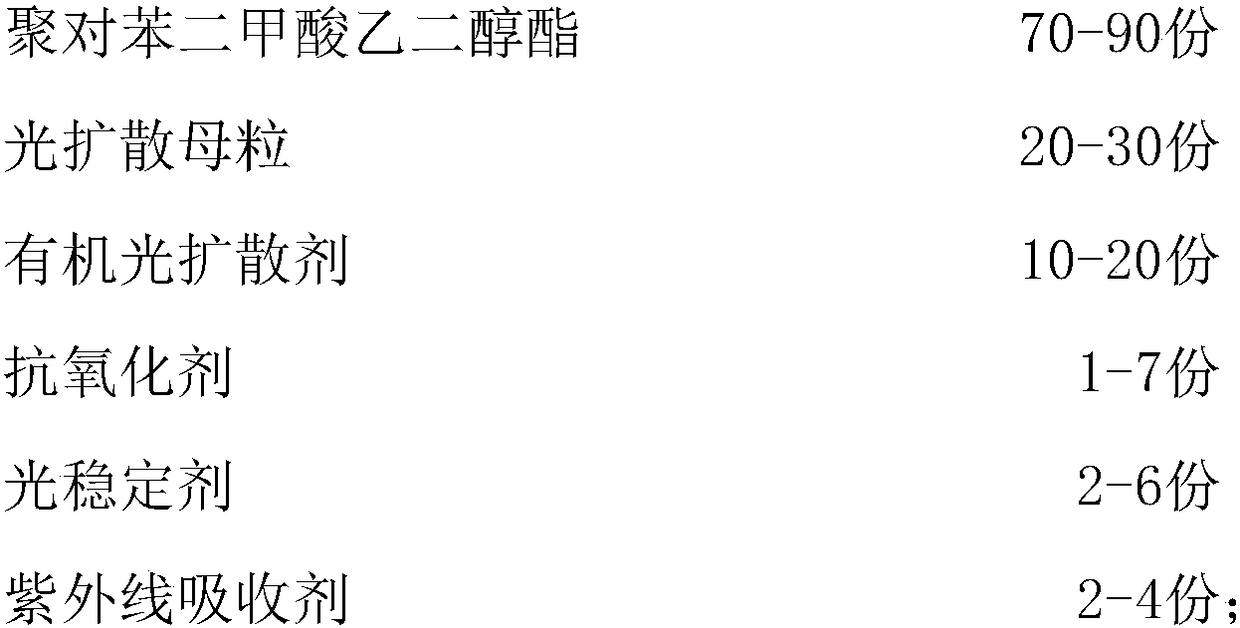

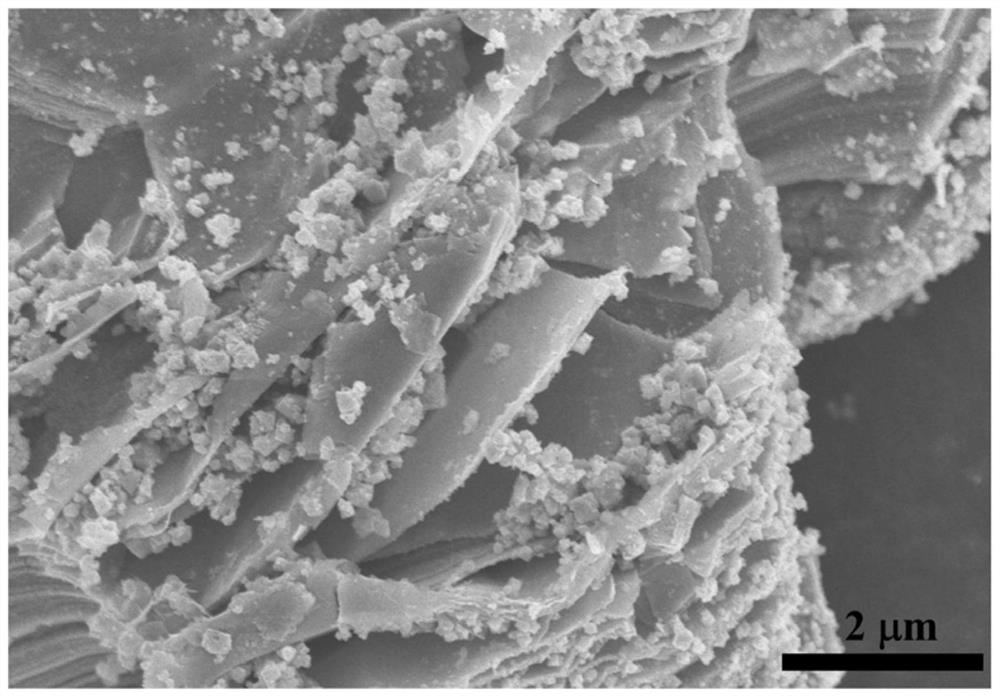

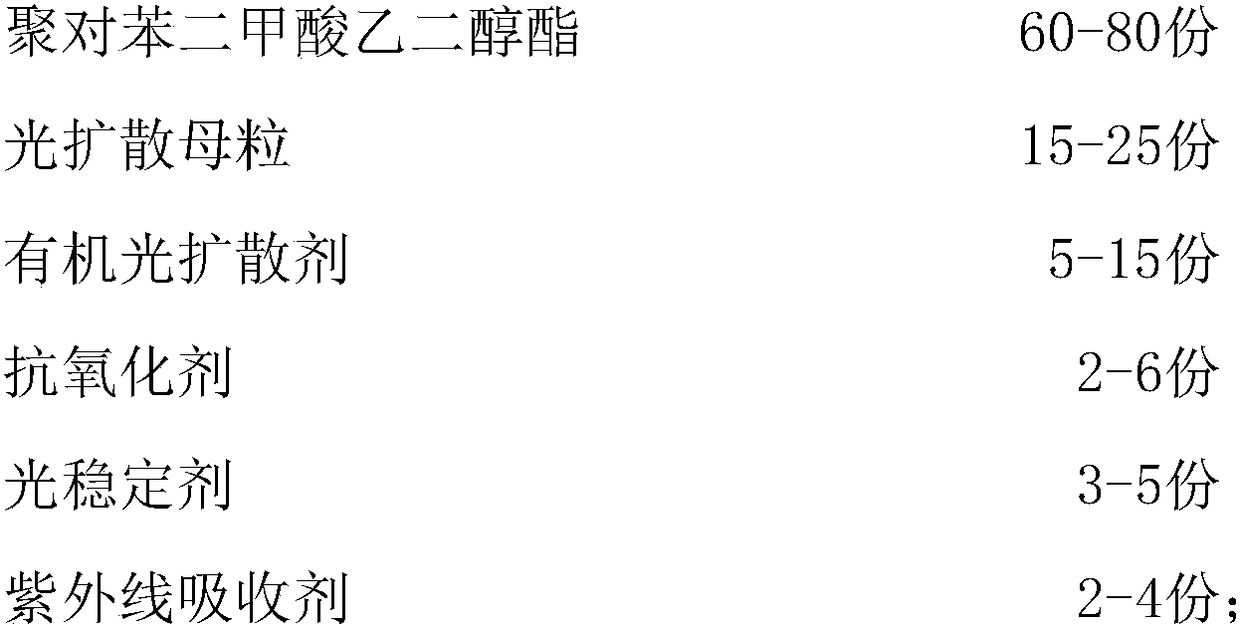

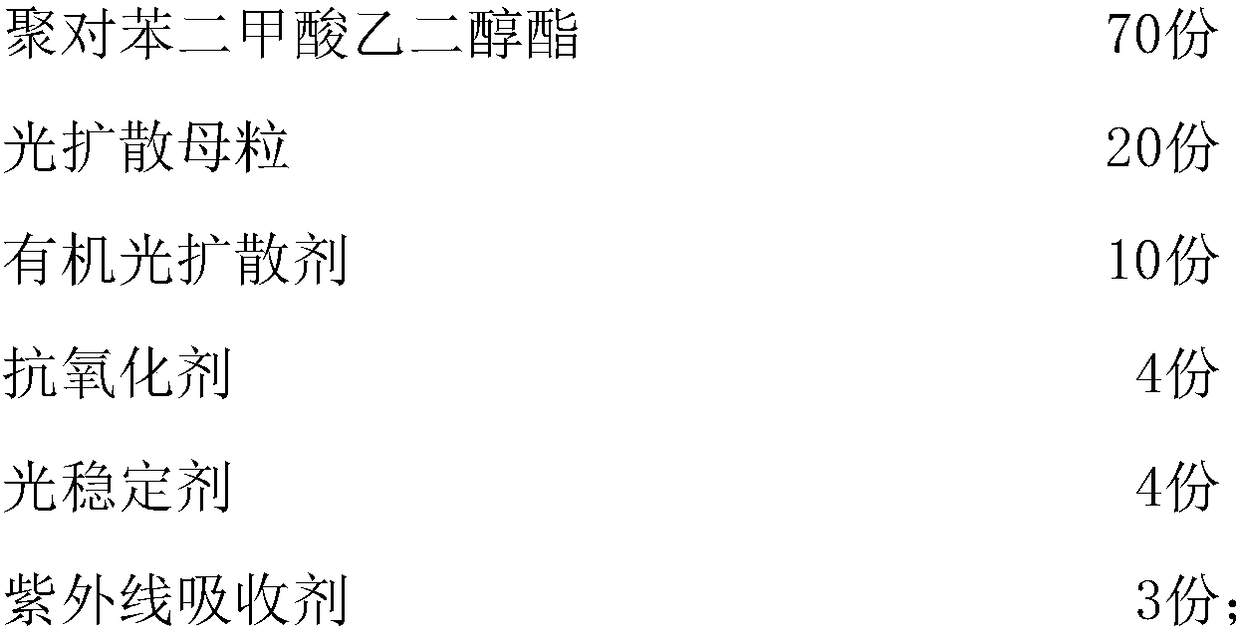

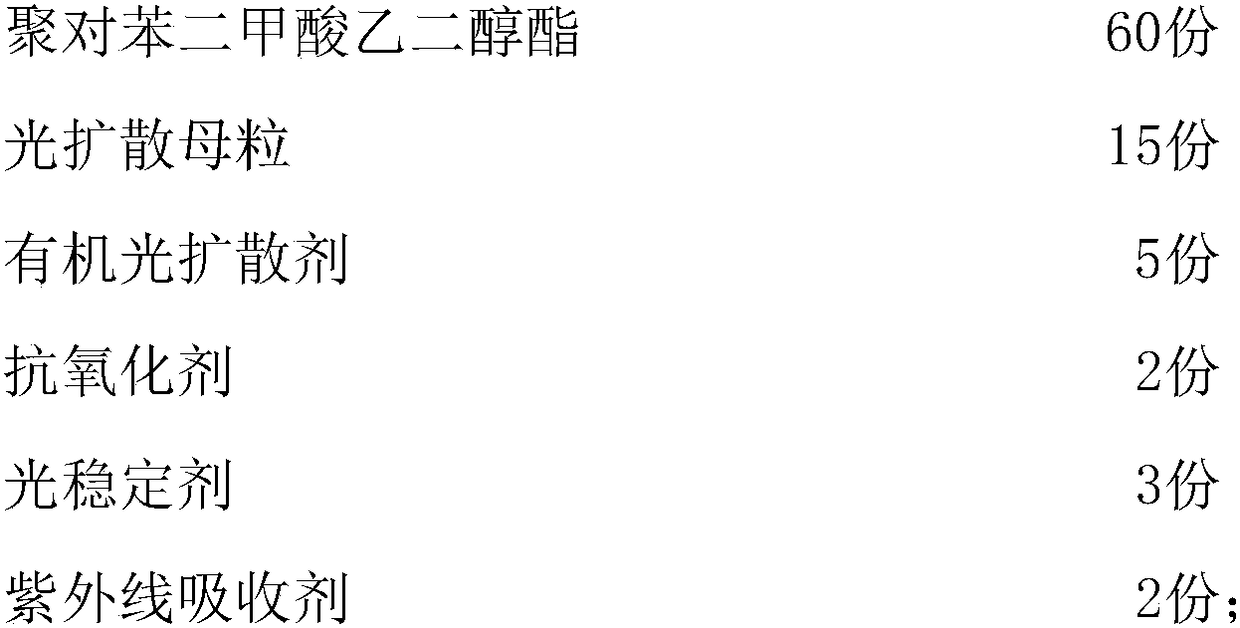

High-resolution liquid crystal display module

InactiveCN108254969AIncrease refractionHigh light transmittanceDiffusing elementsNon-linear opticsMicrosphereMechanical property

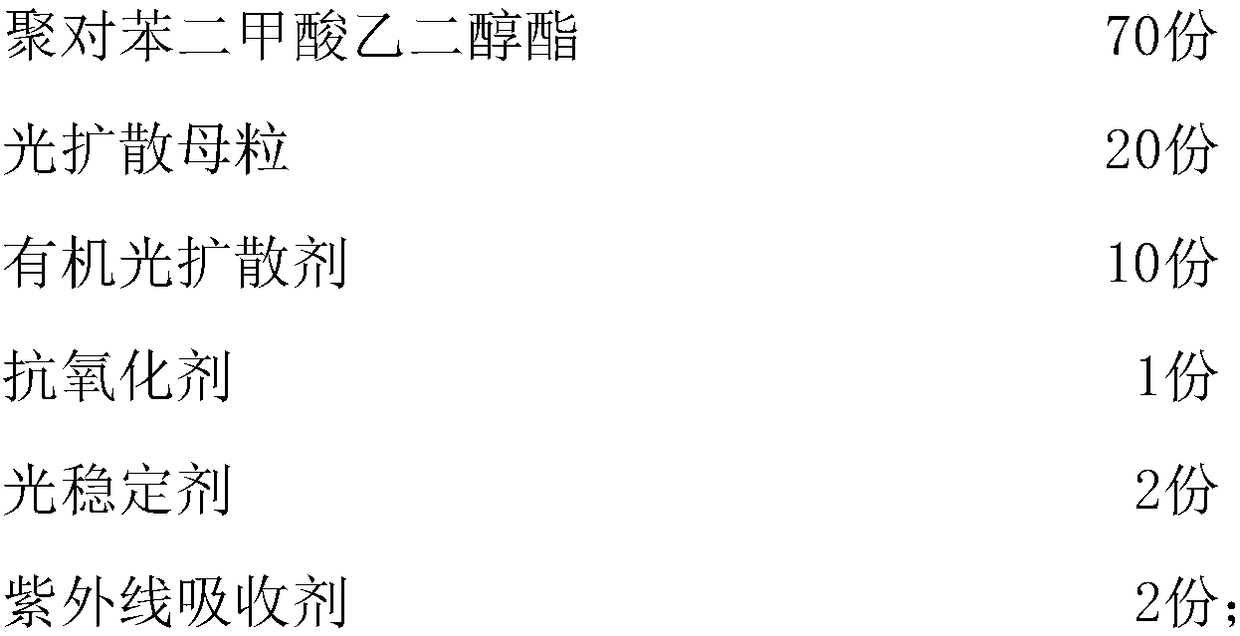

The invention relates to the technical field of liquid crystal displays, in particular to a high-resolution liquid crystal display module. The module comprises a liquid crystal module and a backlightmodule, the backlight module is provided with a light diffusion film, and the light diffusion film comprises polyparaphenylene terephthalaate, light diffusion master batches, an organic light diffusing agent, antioxidant, light stabilizer, ultraviolet absorber and the like. The module adopts polyimide microspheres with better compatibility as a carrier of a nano inorganic light diffusing agent, and effectively solves the problems that the nano inorganic light diffusing agent is easy to agglomerate, difficult to disperse and incompatible with PET resin, the nano inorganic light diffusing agentcan make the light diffusion film of the module have the advantages of high haze, high refraction, high light transmittance and low chromaticity due to the size effect of the nano inorganic light diffusing agent, and the nano inorganic light diffusing agent not only has good optical performance, but also improves the color gamut of the display module, has excellent mechanical properties, and can improve the durability and applicability of the display module.

Owner:JIANGXI PINGBO ELECTRONICS

Intelligent building coating for purifying air and preparation method of intelligent building coating

InactiveCN108912893ALow application efficiencyImprove photocatalytic performanceCoatingsEmulsionAtmospheric air

The invention belongs to the technical field of building coatings, and provides an intelligent building coating for purifying air and a preparation method of the intelligent building coating. According to the method, firstly, titanium dioxide, polyurethane and large-piece-diameter mica powder are assembled for forming spherical particles, and then the spherical particles are combined with an acrylic emulsion, cellulose, organic pigment, a penetrating agent, an organic liquid, an antifreezing agent and a mildew preventive, so that the building coating is prepared. Compared with a coating prepared by a conventional method, the intelligent building coating prepared by the preparation method disclosed by the invention is provided with the nano titanium dioxide and the organic pigment which areuniformly dispersed in the coating and are firmly fixed, so that the coloring is stable, an excellent exterior decoration effect is achieved, and the titanium dioxide does not fall off. The buildingcoating has excellent photocatalytic activity, can capture pollutants in the air and degrades the pollutants, and thus has a remarkable effect of purifying atmospheric air.

Owner:CHENDU NEW KELI CHEM SCI CO LTD

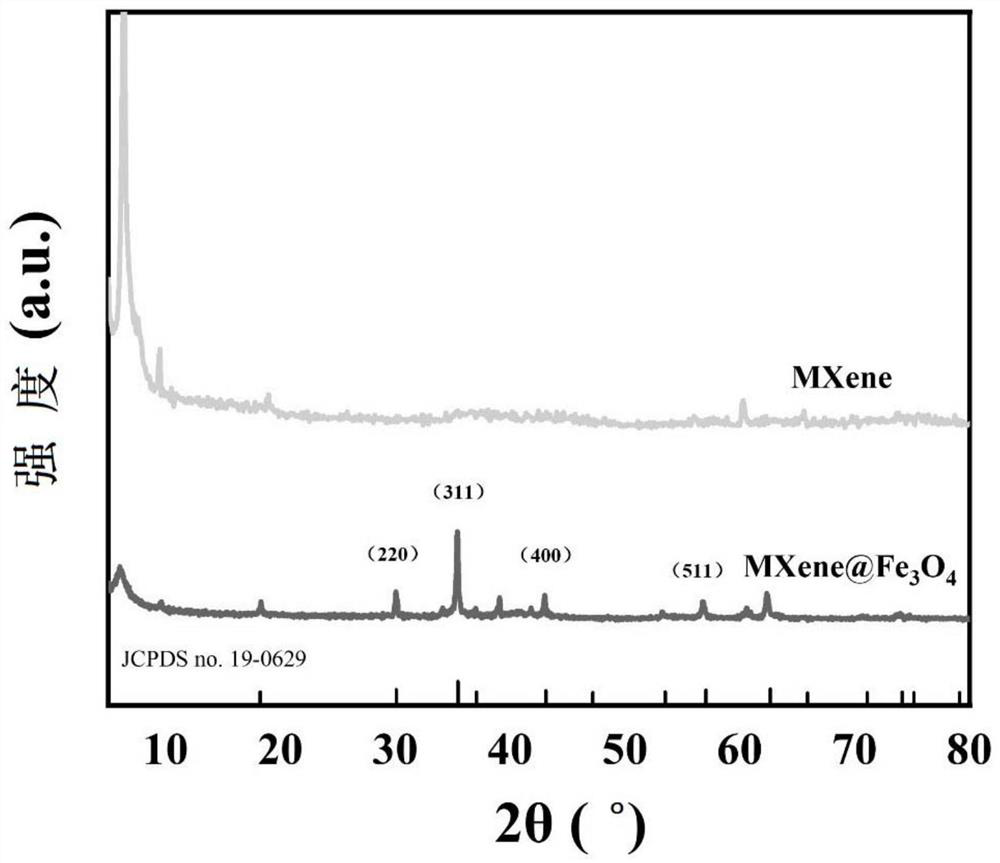

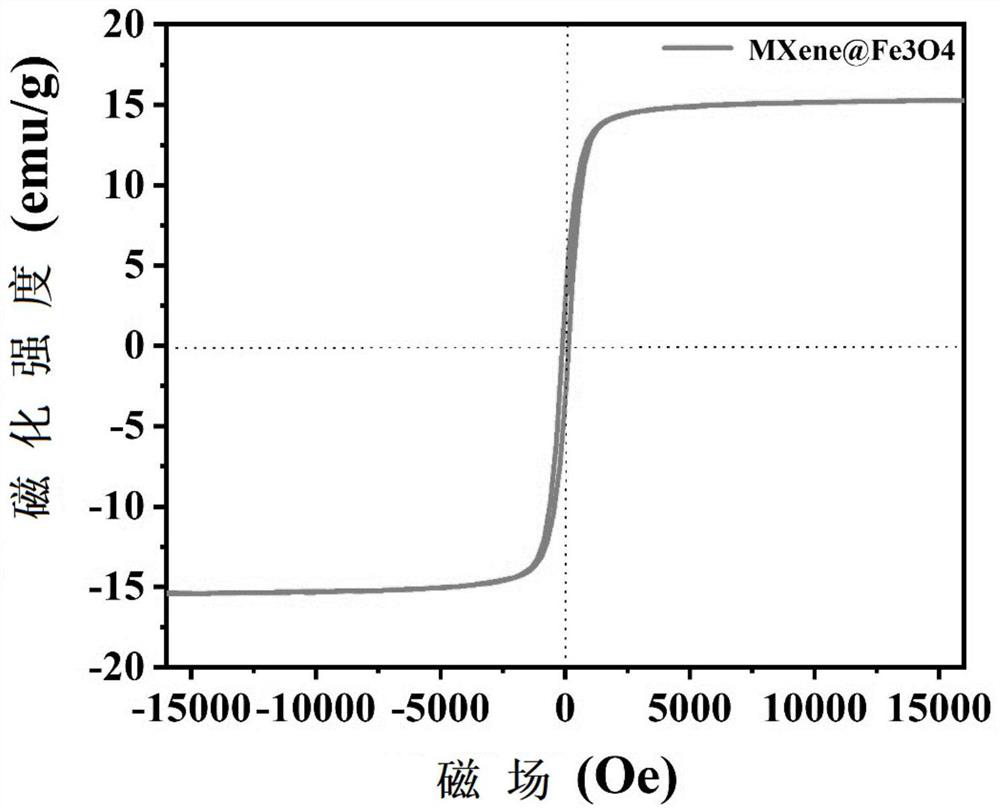

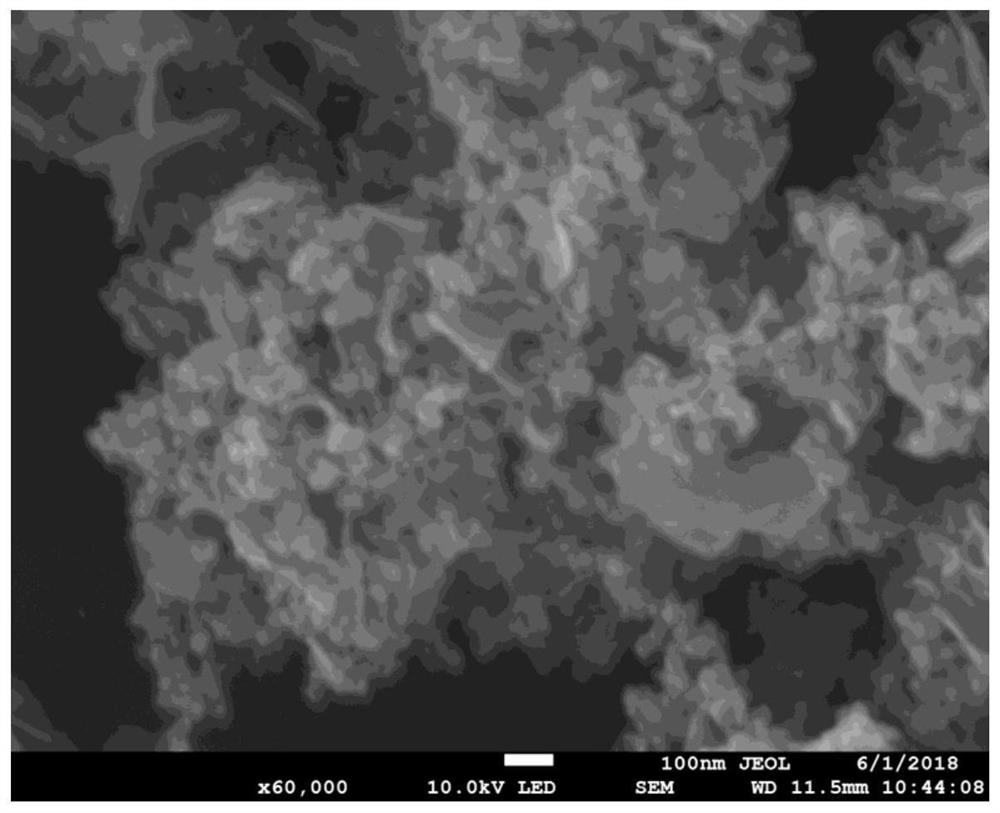

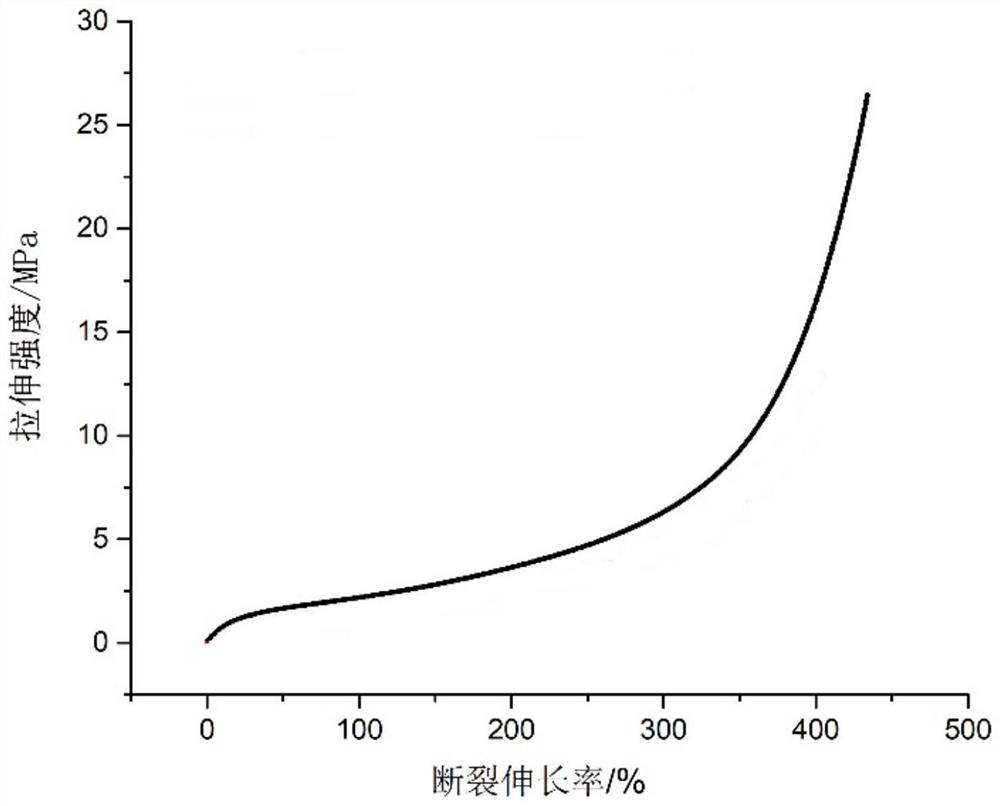

Light energy and magnetic energy dual-driven composite phase change material

ActiveCN113462367ASolve easy reunionAchieve radial migrationHeat-exchange elementsLight energyComposite material

The invention discloses a composite phase change material driven by light energy and magnetic energy. The composite phase change material comprises an MXene matrix; the magnetic metal oxide is doped on the inner surface and the outer surface of the MXene substrate; and the phase change material is compounded in the MXene matrix. The composite phase-change material has high-efficiency light energy and magnetic energy dual-drive energy conversion performance.

Owner:苏州双碳新材料有限公司

Anti-conglutinant master batch and PETG (polyethylene terephthalate glycol) thin film and preparation method thereof

ActiveCN108219393ASolve easy reunionSolving Dispersion ProblemsMicroballoon preparationMicrocapsule preparationPolyethylene terephthalate glycolCarbon fibers

The invention relates to the technical field of function modification of plastics, in particular to an anti-conglutinant master batch and a PETG thin film and a preparation method thereof. The anti-conglutinant master batch is prepared from the raw materials such as substrate resin, anti-conglutinant microspheres, an antioxidant, a light stabilizer and an ultraviolet light absorbing agent. Polyacrylonitrile carbon fiber which has good compatibility with PETG resin and has appropriate strength serves as a carrier of a nano anti-conglutinat agent, the problems that the nano anti-conglutinant agent is prone to agglomerating, hard to disperse and not compatible with the substrate resin are solved, meanwhile, the nano anti-conglutinant agent can make the polyacrylonitrile carbon fiber have theuneven surface due to the size effect of the nano anti-conglutinant agent, accordingly the roughness of the thin film is improved, however, the hardness of salient points of the thin film cannot be super high, so the thin film is not easy to damage; in addition, the polyacrylonitrile carbon fiber can serve as an enhancing filling material to enhance the mechanical properties, such as tensile strength and impact resistance, of the master batch.

Owner:DONGGUAN JISHUO IND CO LTD

Hydrogenated nitrile rubber reinforcing agent as well as preparation method and application thereof

ActiveCN114716743AGood dispersionImproved resistance to hot air agingRolling resistance optimizationNitrile rubberAcrylonitrile

According to the hydrogenated butadiene-acrylonitrile rubber reinforcing agent disclosed by the invention, the hydrogenated butadiene-acrylonitrile rubber reinforcing agent is a compound of flaky hydrotalcite and nano silicon dioxide particles, the nano silicon dioxide particles are taken as a carrier, and the flaky hydrotalcite grows on the surfaces of the nano silicon dioxide particles; in the compound, the weight ratio of the flaky hydrotalcite to the nano silicon dioxide particles is (0.2-1): 1. The hydrogenated butadiene-acrylonitrile rubber reinforcing agent disclosed by the invention is a compound of flaky hydrotalcite and nano silicon dioxide particles, the nano silicon dioxide particles are used as a carrier, and the flaky hydrotalcite grows on the surfaces of the nano silicon dioxide particles; the modified nano silicon dioxide particles as a reinforcing agent of hydrogenated nitrile butadiene rubber have good reinforcing property and excellent dispersity in hydrogenated nitrile butadiene rubber, and the flaky hydrotalcite can generate orientation behavior when the rubber is subjected to tensile force, so that the stress transfer rate is increased, and the reinforcing agent is more efficient.

Owner:CHENGDU AIRCRAFT INDUSTRY GROUP

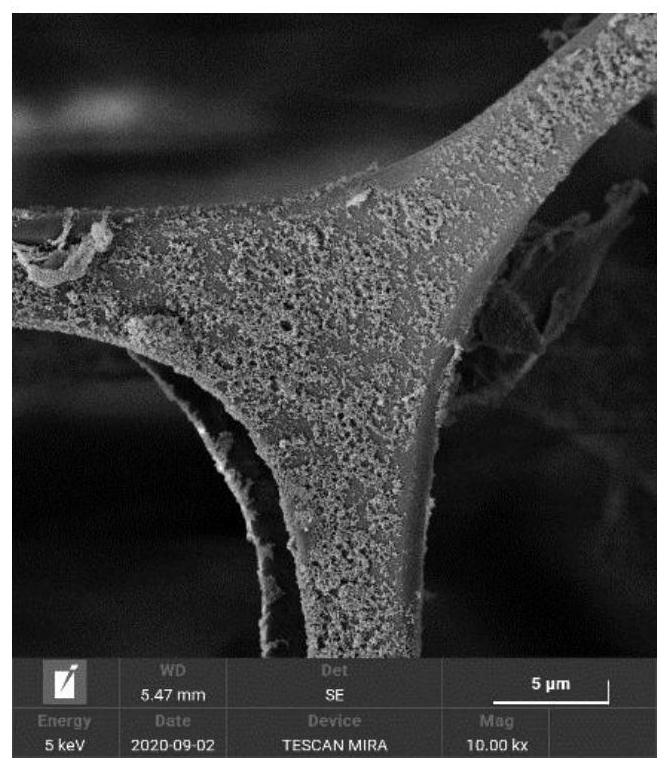

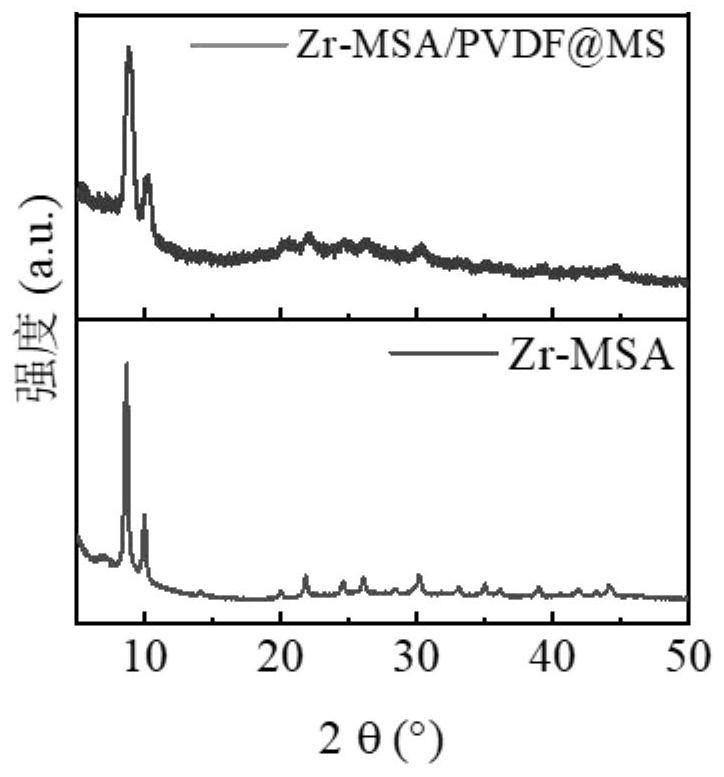

Heavy metal mercury adsorbent and preparation method thereof

InactiveCN112934204ASolve easy reunionSolve difficult recycling problemsOther chemical processesWater contaminantsOrganosolvSorbent

The invention discloses a heavy metal mercury (Hg) adsorbent and a preparation method thereof, and belongs to the technical field of heavy metal wastewater treatment. The heavy metal mercury adsorbent is characterized in that porous melamine sponge is used as a carrier material, a net film is formed by means of the thermally induced phase separation characteristic of PVDF, and due to the strong hydrogen-bond interaction between PVDF and Zr-MSA nano-particles, Zr-MSA nanoparticles are stably fixed on fiber bundles in the porous melamine sponge by the PVDF net film, so that the problems that Zr-MSA powder is easy to agglomerate, difficult to separate and difficult to reuse are solved. The heavy metal mercury adsorbent prepared by the method has super-strong stability, excellent acid resistance, alkali resistance and organic solvent resistance, can be used as an efficient and stable heavy metal mercury adsorption material, has higher heavy metal Hg (II) adsorption capacity and higher adsorption kinetics rate, can remove heavy metal Hg (II) in a water solution from a complex water body in a targeted manner, and is excellent in reutilization performance.

Owner:SHANGHAI JIAO TONG UNIV +1

Narrow frame TFT liquid crystal display module

InactiveCN108303820AStrong absorption capacityAvoid damageNon-linear opticsMicrospherePolyethylene glycol

The invention relates to the technical field of liquid crystal displayers, in particular to a narrow frame TFT liquid crystal display module which comprises a backlight module and a display module; the display module comprises a color film substrate and a thin film transistor substrate which are stacked; a light diffusion film is arranged on the backlight module and prepared from polyethylene glycol terephthalate, light diffusion mater batches, an organic light diffusion agent, an anti-oxidant, a light stabilizer, an ultraviolet light absorber and the like. Polyacrylamide microspheres with thegood compatibility are adopted as a carrier of a nanometer inorganic light diffusion agent, the problem that the nanometer inorganic light diffusion agent is likely to be aggregated, is not likely todisperse and is not compatible with PET resin is effectively solved, due to the size effect of the nanometer inorganic light diffusion agent, the light diffusion film has the advantages of being highin haze, refraction, light transmission rate, ground color degree and the like, the good optical performance is achieved, the color gamut of the display module can be improved, the excellent mechanical property is achieved, and the durability and adaptability of the display module can be improved.

Owner:JIANGXI PINGBO ELECTRONICS

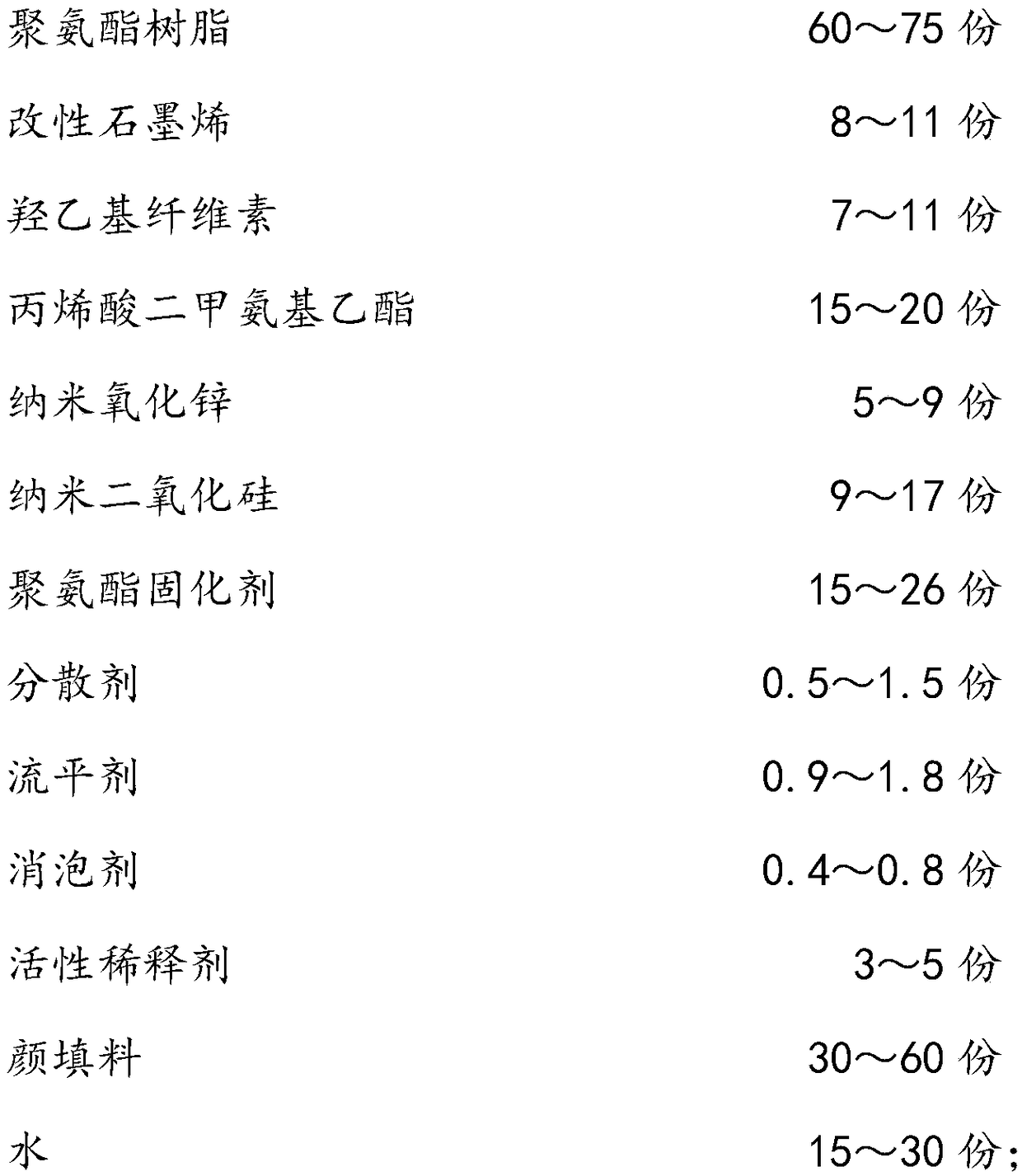

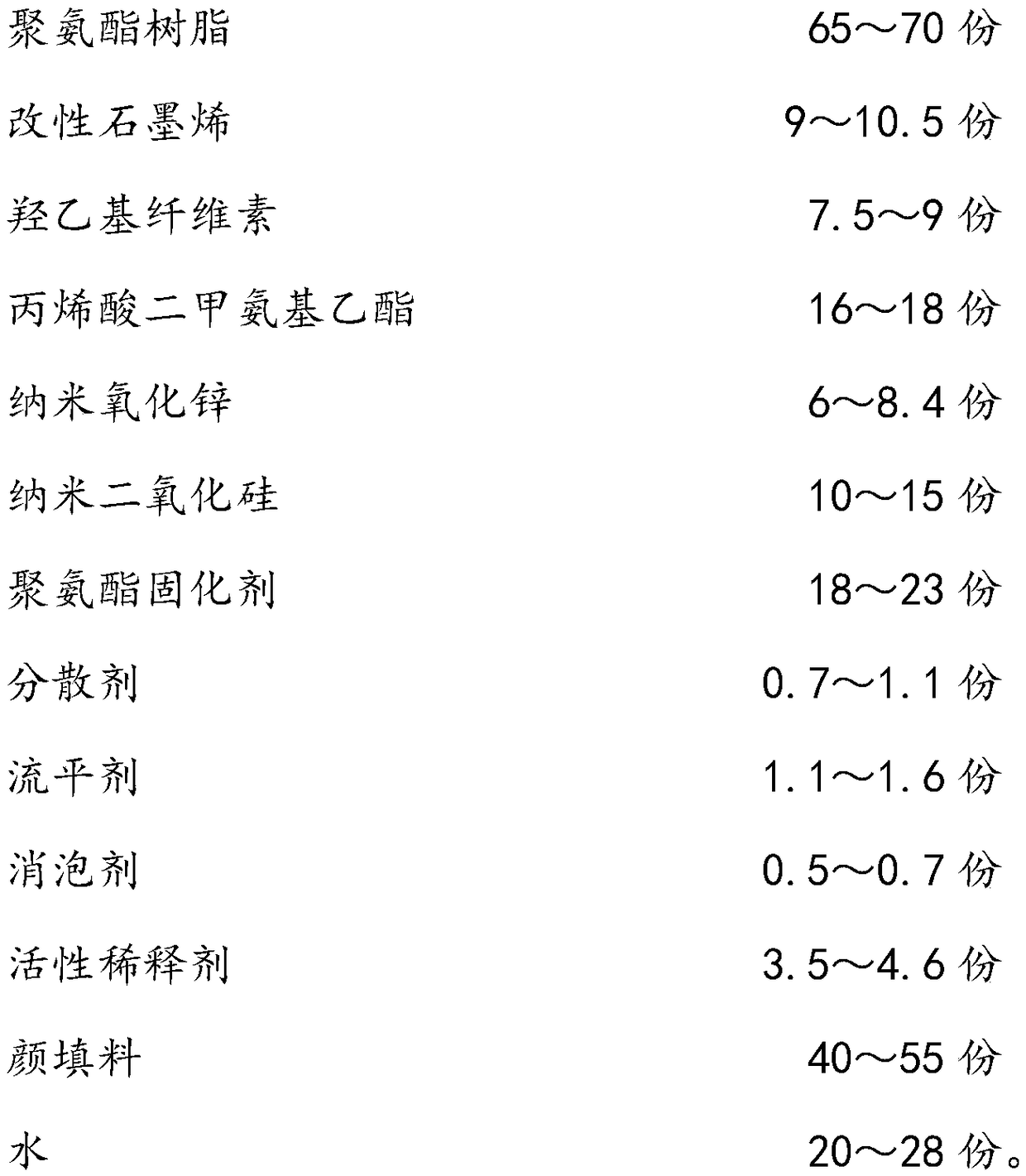

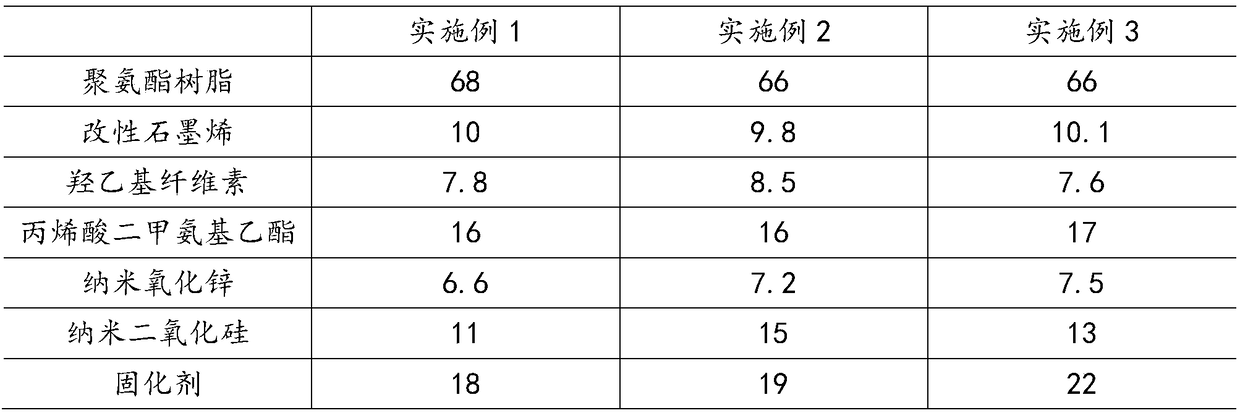

Graphene waterborne super-wear-resisting floor paint and preparation method thereof

ActiveCN108795126ASolve easy reunionImprove wear resistanceAnti-corrosive paintsEnvironmental resistanceFoaming agent

The invention provides graphene waterborne super-wear-resisting floor paint and a preparation method thereof. The floor paint is prepared from the following components in parts by weight: 60 to 75 parts of polyurethane resin, 8 to 11 parts of modified graphene, 7 to 11 parts of hydroxyethyl cellulose, 15 to 20 parts of dimethylaminoethyl acrylate, 5 to 9 parts of nano zinc oxide, 9 to 17 parts ofnano silicon dioxide, 15 to 26 parts of curing agent, 0.5 to 1.5 part of dispersant, 0.9 to 1.8 parts of flatting agent, 0.4 to 0.8 part of de-foaming agent, 3 to 5 parts of active diluting agent, 30to 60 parts of pigment and filler and 15 to 30 parts of water. According to the graphene waterborne super-wear-resisting floor paint provided by the invention, the wear-resisting performance and mechanical performance of a coating paint film are enhanced; a preparation technology is simple and a prepared product meets the environment-friendly requirements; the graphene waterborne super-wear-resisting floor paint is safe and environmentally friendly and has a wide applicable range.

Owner:厦门中凯新材石墨烯科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com