Method for efficiently and fast removing antipyrine by using MnOx/SBA-15-PMS compound system and application

An anti-aging and efficient technology, applied in chemical instruments and methods, water/sewage treatment, chemical/physical processes, etc., can solve the problem of mineralization rate reaching 60%, inconvenient storage and transportation, narrow pH operating range, etc. problem, to achieve the effect of simple and feasible preparation method, reusable regeneration performance, and equipment requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Example 1: Preparation and characterization of mesoporous silica (SBA-15) carrier, this example is a control experiment of the method of the present invention. The details are as follows.

[0031] (1) Mesoporous SBA-15 was synthesized according to the method reported in the literature ( Science , 1998, 279 (5350), 548-552): Weigh 4.000 g of poly(ethylene glycol)-poly(propylene glycol)-poly(ethylene glycol) polymer (P-123) and place in 125 mL 2 M HCl solution in a clean beaker, placed in a 311 K water bath and stirred for 24 h; after P-123 was fully dissolved, 8.17 g of tetraethyl silicate (TEOS) was added, continued to be placed in a 311 K water bath and stirred for 24 h, and then dissolved at 373 K hydrothermal reaction for 24 h; cooling, filtering and washing, drying, calcination at 823 K for 6 h, and grinding to obtain SBA-15.

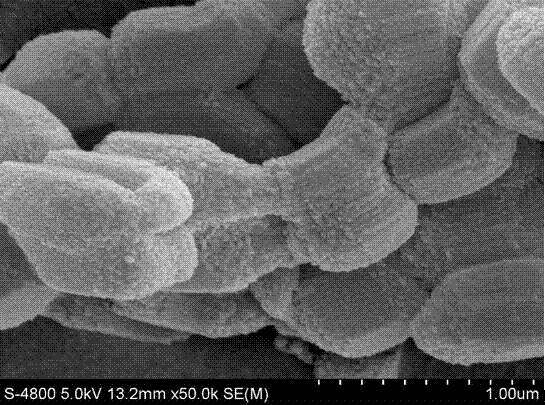

[0032] (2) Field emission scanning electron microscopy (FE-SEM) characterization of the mesoporous SBA-15 prepared in this example (see ...

Embodiment 2

[0033] Embodiment 2: This MnO x / SBA-15 (MS) composite material preparation, the details are as follows.

[0034] (1) First prepare the mesoporous SBA-15 carrier according to Example 1.

[0035] (2) Prepare 90MS 6 (823,3) Composite material: Weigh 0.1604 g (0.6546 mmol) of Mn(CH 3 COO) 2 ?4H 2 O and use it in an appropriate amount of deionized water, then add 0.6 g of SBA-15, put it in 348 K for drying after ultrasonication for 90 min; then place the dried sample in a muffle furnace at 823 K for 3 h K / min), after cooling down to room temperature, the sample obtained after grinding is 90MS 6 (823,3) Composite material, stored for future use.

[0036] (3) According to step (2) of this embodiment, Mn(CH 3 COO) 2 ?4H 2 O dosage, sonication time, drying temperature, calcination temperature and time were changed to 0.1069 g (0.4364 mmol), 60 min, 333 K, 723 K and 2 h to prepare 60MS 4 (723,2) Composite material, store for future use.

[0037] (4) According to step (2) of ...

Embodiment 3

[0038] Example 3: Different MS composite materials catalyzed PMS to degrade antipyrin in water, the specific content is as follows.

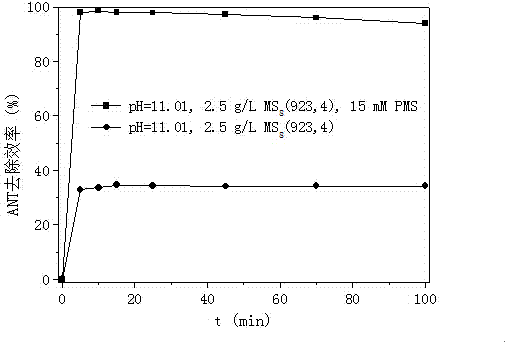

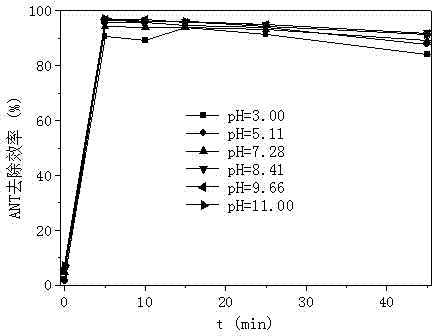

[0039] (1) Investigate 120MS 8 (923,4)-PMS composite system degrading antipyrine efficiency in water: 120MS was prepared according to the method described in Example 2 8 (923,4) composites. Prepare an aqueous solution with a concentration of 50 mg / L antipyrine and adjust its pH to 11. Measure 80 mL of antipyrine aqueous solution with a concentration of 50 mg / L in 4 clean reaction vials and number them, add 120MS to No. 1 reaction vial 8 (923,4) composite material (2.5 g / L) and PMS (15 mM), 120MS was added to the No. 2 reaction bottle 8 (923,4) Composite material (2.5 g / L), PMS (15 mM) was added to No. 3 reaction bottle, no material was added to No. 4 reaction bottle (control sample), and stirred at room temperature (300 rpm) for 100 min. At regular intervals, 2 mL water samples were taken for analysis.

[0040] (2) Draw the data obtained fr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| clearance rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com