Yellowing-resisting, whitening and brightening master batch, polyester recycled material and preparation method

A masterbatch and polyester technology, which is applied in the field of polyester regeneration, can solve the problems of yellowing, aging, and application restrictions of recycled polyester, and achieve the effect of enhancing tensile strength and solving the problem of easy agglomeration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

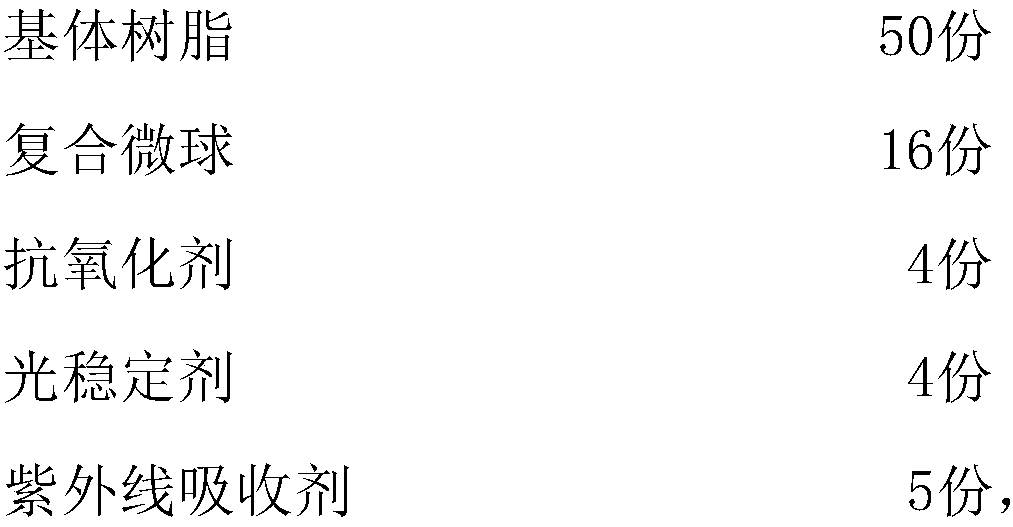

[0029] A masterbatch for reducing yellowing, whitening and brightening, comprising the following raw materials in parts by weight:

[0030]

[0031] The composite microsphere is a microsphere with a core-shell structure, the core of the core-shell structure microsphere is nano titanium dioxide, and the shell is polyacrylonitrile.

[0032] Wherein, the average particle diameter of the nano-titanium dioxide is 40nm.

[0033] Wherein, the preparation method of the composite microsphere comprises the following steps: (1) taking a certain amount of N,N-dimethylformamide to dissolve the polyacrylonitrile to form a polyacrylonitrile solution; (2) dissolving the nano Titanium dioxide is added to the polyacrylonitrile solution obtained in step (1), and ultrasonically dispersed to obtain a precursor solution; (3) the precursor solution obtained in step (2) is electrostatically sprayed to obtain the composite Microspheres.

[0034] Wherein, the particle diameter of the composite mic...

Embodiment 2

[0046] A masterbatch for reducing yellowing, whitening and brightening, comprising the following raw materials in parts by weight:

[0047]

[0048] The composite microsphere is a microsphere with a core-shell structure, the core of the core-shell structure microsphere is nano titanium dioxide, and the shell is polyacrylonitrile.

[0049] Wherein, the average particle diameter of the nano-titanium dioxide is 30nm.

[0050] Wherein, the preparation method of the composite microsphere comprises the following steps: (1) taking a certain amount of N,N-dimethylformamide to dissolve the polyacrylonitrile to form a polyacrylonitrile solution; (2) dissolving the nano Titanium dioxide is added to the polyacrylonitrile solution obtained in step (1), and ultrasonically dispersed to obtain a precursor solution; (3) the precursor solution obtained in step (2) is electrostatically sprayed to obtain the composite Microspheres.

[0051] Wherein, the particle diameter of the composite mic...

Embodiment 3

[0063] A masterbatch for reducing yellowing, whitening and brightening, comprising the following raw materials in parts by weight:

[0064]

[0065] The composite microsphere is a microsphere with a core-shell structure, the core of the core-shell structure microsphere is nano titanium dioxide, and the shell is polyacrylonitrile.

[0066] Wherein, the average particle diameter of the nano-titanium dioxide is 50nm.

[0067] Wherein, the preparation method of the composite microsphere comprises the following steps: (1) taking a certain amount of N,N-dimethylformamide to dissolve the polyacrylonitrile to form a polyacrylonitrile solution; (2) dissolving the nano Titanium dioxide is added to the polyacrylonitrile solution obtained in step (1), and ultrasonically dispersed to obtain a precursor solution; (3) the precursor solution obtained in step (2) is electrostatically sprayed to obtain the composite Microspheres.

[0068] Wherein, the particle diameter of the composite mic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com