Heavy metal mercury adsorbent and preparation method thereof

A technology for adsorbents and heavy metals, applied in alkali metal compounds, chemical instruments and methods, adsorption water/sewage treatment, etc., can solve the problems of inability to meet environmental water quality standards for polluted water bodies, low adsorption affinity, and poor adsorption selectivity. Achieve excellent acid and alkali resistance, high adsorption capacity, and high economic value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] Embodiment 1: Preparation of Zr-MSA nanoparticles

[0043] 23.3g ZrCl 4 Dissolve 15g of mercaptomalic acid (MSA) in 200mL of deionized water, and after ultrasonic treatment for 1 minute, add 13mL of formic acid; cover the bottle, and place the above solution in an oven at 80°C for 3h; wait to cool to room temperature Finally, the obtained white precipitate was centrifuged, washed 4 times with deionized water, and freeze-dried for 24 hours to obtain Zr-MSA nanoparticles.

Embodiment 2

[0044] Embodiment 2: Preparation of Zr-MSA / PVDF / DMF ternary mixed solution

[0045]Take 2 g of the Zr-MSA powder obtained in Example 1 and disperse it in 100 mL of DMF solvent. After stirring for 5 min, use a cell disruptor (1200 w) to sonicate the Zr-MSA particles for 15 min under ice bath conditions to make the Zr-MSA particles highly dispersed; heat and stir at 50 ° C Slowly add 2g of PVDF powder into the Zr-MSA / DMF mixed solution, and stir it magnetically for 2 hours to obtain a uniformly dispersed Zr-MSA / PVDF / DMF ternary mixed solution.

Embodiment 3

[0046] Embodiment 3: the preparation of heavy metal mercury adsorbent

[0047] Take the cut melamine sponge (1.5×1.5×5cm 3 ) impregnated in the Zr-MSA / PVDF / DMF ternary mixed solution of embodiment 2 gained, take out sponge after repeatedly extruding 5 times and drain the dispersion liquid of surface adhesion; In the process, the temperature was raised to 150 °C and kept for 3 hours, and the oven was cooled to room temperature, and the heavy metal mercury adsorbent Zr-MSA / PVDF@MS with high stability was obtained. After testing, the loading of Zr-MSA nanoparticles in the heavy metal mercury adsorbent is about 37.0wt%.

[0048] figure 1 It is the photogram of the heavy metal mercury sorbent prepared by embodiment 3, and the appearance of the heavy metal mercury sorbent prepared by the above-mentioned method is pale yellow.

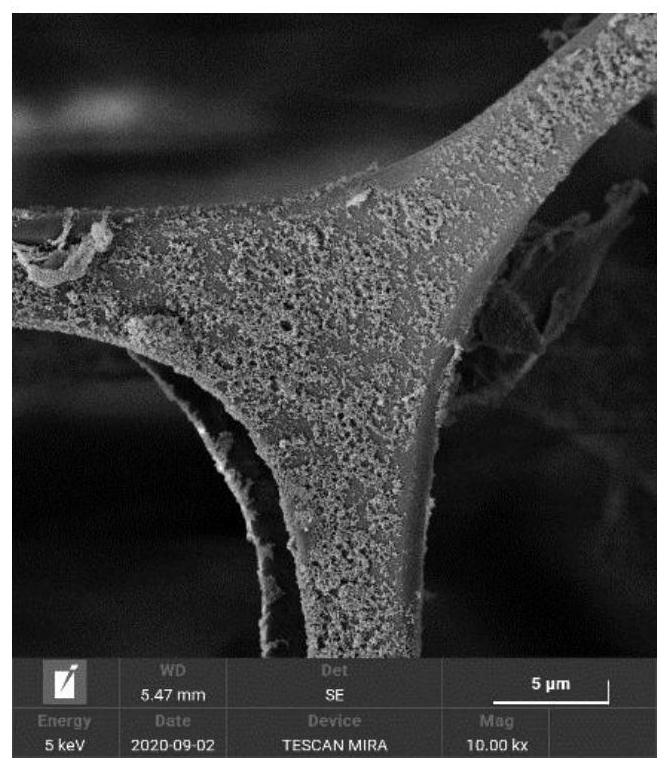

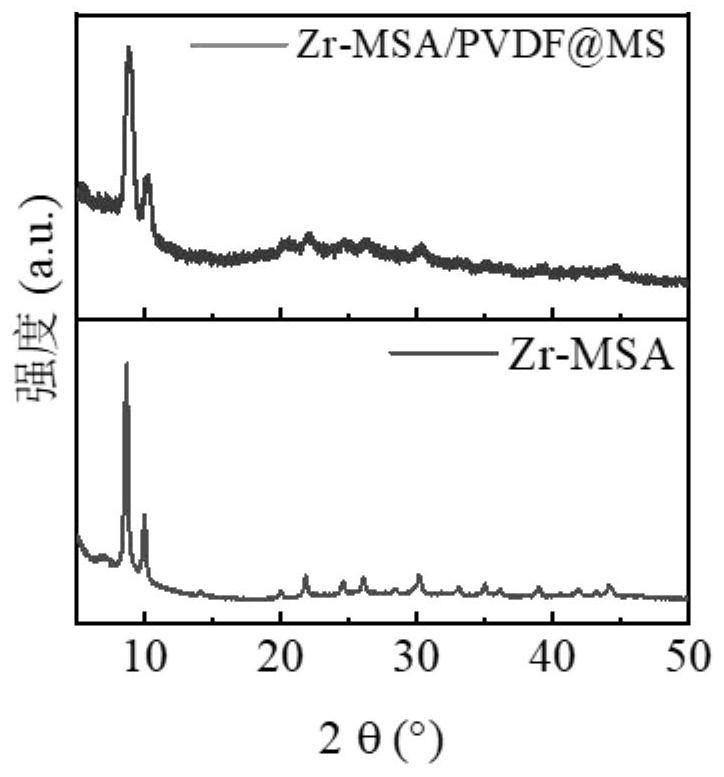

[0049] figure 2 It is the SEM figure of the heavy metal mercury sorbent prepared in embodiment 3, Zr-MSA nanoparticles are evenly distributed on the hea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com