Light energy and magnetic energy dual-driven composite phase change material

A composite phase change material and a technology of phase change materials, which are applied in the field of optical energy and magnetic energy dual-driven composite phase change materials, can solve the problems such as the inability to meet the urgent needs in the field of energy conversion and thermal energy storage, and achieve improved photothermal conversion efficiency and good economical efficiency. Sex, solve the effect of single functional

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0057] In the second aspect, the present application also provides a method for preparing the above-mentioned light energy and magnetic energy double-driven composite phase change material, which includes the following steps:

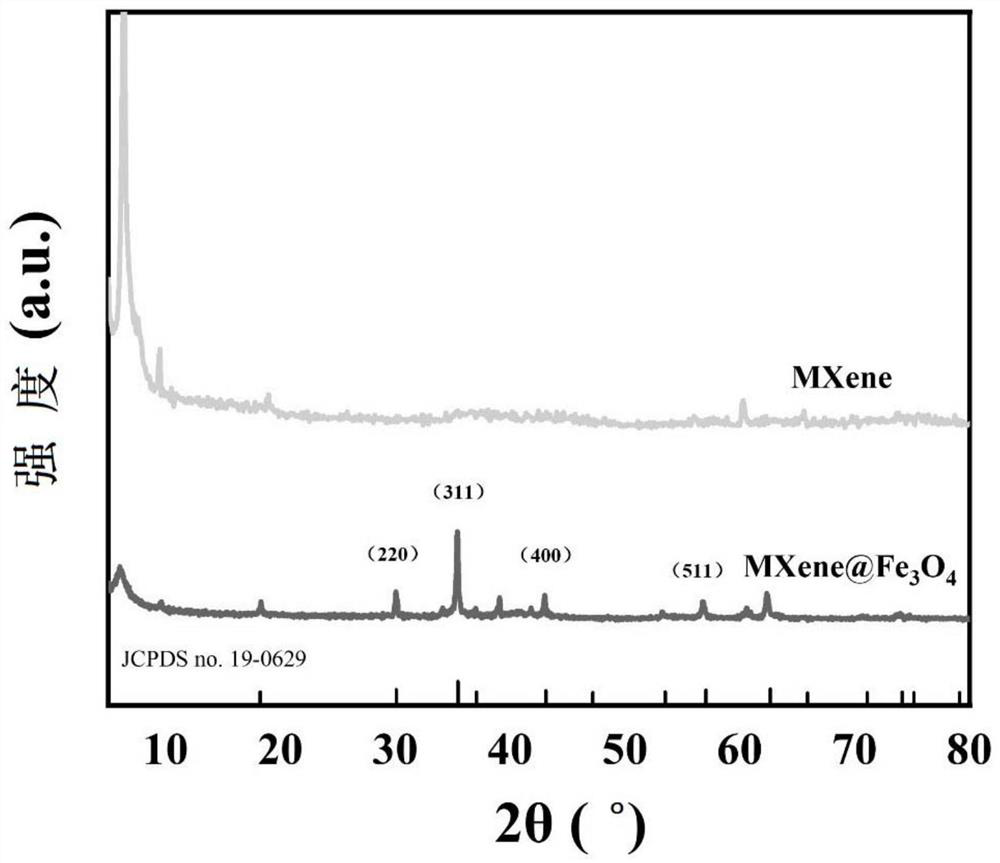

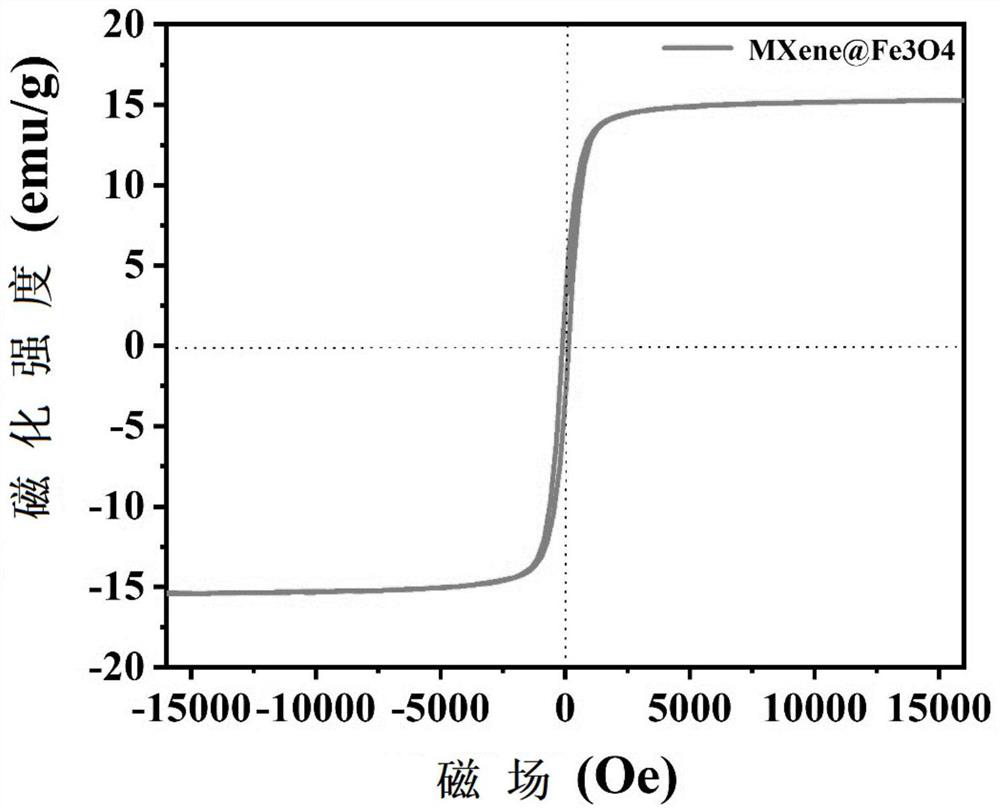

[0058] (1) Using MXene as a photon trap, by in-situ chemical synthesis method, doping magnetic metal oxides on its surface and interlayers to obtain MXene composite phase change carrier doped with magnetic metal oxides; and

[0059] (2) Composite the MXene composite phase-change carrier doped with magnetic metal oxides obtained in step (1) with the phase-change core material to obtain.

[0060] According to the present application, the advantages of the dual-drive composite phase change material of light energy and magnetic energy include at least the following points: 1) Using in-situ chemical synthesis method to uniformly embed different kinds of magnetic metal oxides on the surface and interlayer of MXene with excellent light absorption performance I...

preparation Embodiment 1

[0068] Adopt following method to prepare according to the MXene of the present application:

[0069] Under vigorous stirring, 1 g of LiF and 1 g of MAX were slowly added into 20 mL of HCl (10 M) solution, and stirred in an oil bath at 35 °C for 36 h. The obtained product was dispersed in deionized water, centrifuged and washed at 3600rmp until the supernatant was neutral. The obtained precipitates were freeze-dried to obtain multilayered MXene powders.

Embodiment 1

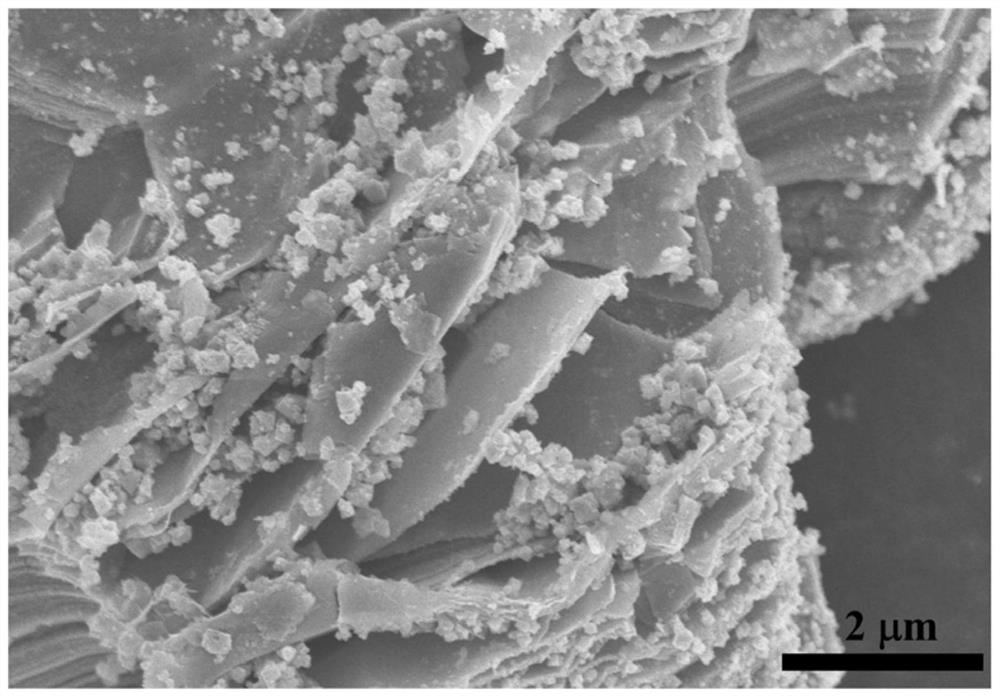

[0071] (1) Disperse 150 mg of MXene powder prepared in Preparation Example 1 in deionized water, heat in an oil bath at 55° C., and add 80 mg of surfactant CTAB to it, and stir for 20 min; then add 187 mg of FeCl 3 ·6H 2 O, and stirred under Ar atmosphere for 30min;; then added 109mg of FeCl to the solution 2 4H 2 O, and NaOH solution was added to adjust the pH value above 10, and then stirred for 4 h. After the stirring, the product was washed with deionized water to neutrality and freeze-dried to obtain a MXene composite carrier doped with magnetic metal oxides, namely MXene@Fe 3 o 4 carrier.

[0072] (2) 0.150 g of MXene@Fe prepared in the above step (1) 3 o 4 The carrier was vacuum-activated at 120°C for 4h, then dispersed in 10mL of anhydrous ethanol solution containing 0.35g of myristic acid (MA), stirred at 60°C for 2h, then the mixture was placed in a drying oven at 80°C, and kept warm 36h, collect MXene@Fe 3 o 4 Composite phase change materials loaded with MA...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com