Preparation method of hydroxylated graphene powder with controllable conductive performance

A technology of hydroxylated graphene and electrical conductivity is applied in the field of preparation of hydroxylated graphene powder, which can solve the problems such as literature reports and the like that have not been disclosed for hydroxylated graphene with controllable conductivity, and achieves excellent solubility, The effect of controlled conductivity and high purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

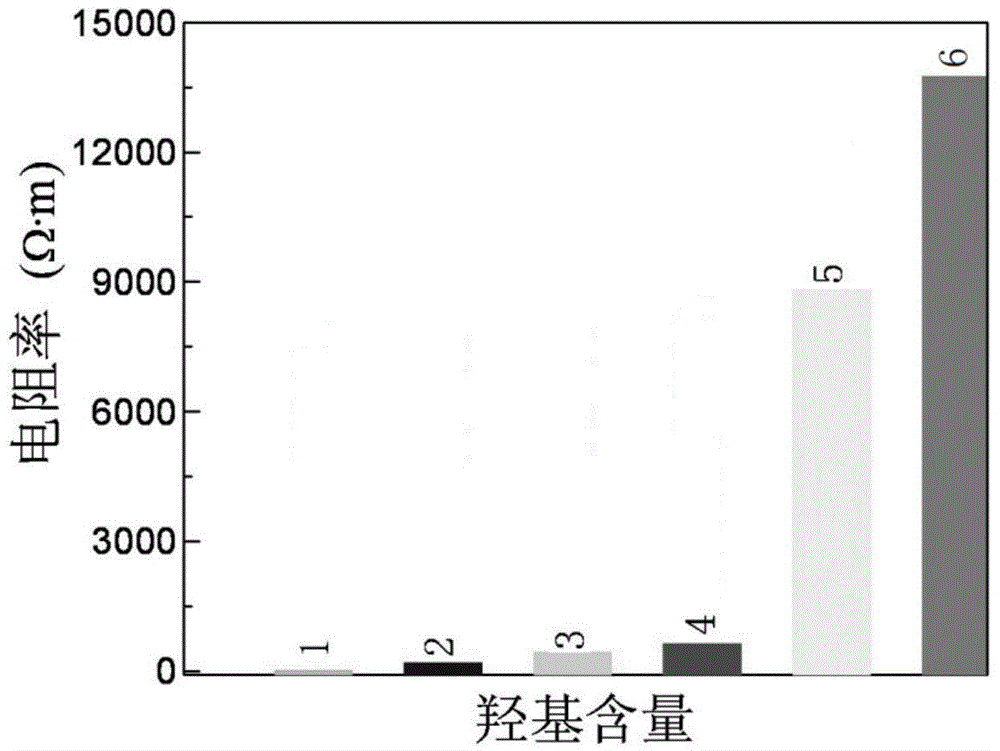

[0027] Take 1L of graphene oxide aqueous solution with a concentration of 1.0g / L, sonicate for 30min, add ammonia water, adjust the pH value to 7-8, add 1.0g of hydrazine hydrate, put the solution in an oil bath at 80°C, condense and reflux for 24h, adjust the oil bath When the temperature reaches 70°C, add 0.181g of aminophenylcarbinol and 0.204g of isoamyl nitrite to the solution, reflux for 36 hours, filter the resulting solution to neutrality, freeze-dry for 5 days, and obtain a hydroxyl content of 5% (100 The number of hydroxyl groups on the benzene ring) of hydroxylated graphene powder, its resistivity is as figure 1 Shown in 1.

Embodiment 2

[0029] Take 1L of graphene oxide aqueous solution with a concentration of 1.5g / L, sonicate for 30min, add ammonia water, adjust the pH value to 7-8, add 2.25g of hydrazine hydrate, put the solution in an oil bath at 85°C, condense and reflux for 24h, adjust the oil bath Temperature to 70°C, add 0.90g aminophenylethanol and 0.673g isoamyl nitrite to the solution, condense and reflux for 36 hours, filter the resulting solution to neutrality, freeze-dry for 5 days, and obtain a hydroxyl content of 15% (100 The number of hydroxyl groups on the benzene ring) of hydroxylated graphene powder, its resistivity is as figure 1 Shown in 2.

Embodiment 3

[0031] Take 1L of graphene oxide aqueous solution with a concentration of 2.0g / L, ultrasonicate for 30min, add ammonia water, adjust the pH value to 8-9, add 4.0g of hydrazine hydrate, put the solution in an oil bath at 90°C, condense and reflux for 36h, adjust the oil bath When the temperature reaches 75°C, add 1.810g of aminophenylcarbinol and 0.836g of isoamyl nitrite to the solution, reflux for 24 hours, filter the resulting solution to neutrality, freeze-dry for 6 days, and obtain a hydroxyl content of 25% (100 The number of hydroxyl groups on the benzene ring) of hydroxylated graphene powder, its resistivity is as figure 1 Shown in 3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com