TiO2/sepiolite composite gel with 001 and 101 crystal planes exposed and preparation method of TiO2/sepiolite composite gel

A technology of composite gel and sepiolite, which is applied in chemical instruments and methods, alkali metal compounds, other chemical processes, etc., can solve problems such as inability to solve the problem of TiO2 aggregation, and achieves the solution of difficult solid-liquid separation, low production cost, Structured novel effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052] (1) Add a certain amount of titanium source into the acetic acid solution, stir and dissolve at 40°C for 24 hours, wherein the mass ratio of titanium to acetic acid (analytical pure) is 0.28:40, and the titanium source in this example is tetrabutyl titanate ester;

[0053] (2) A certain amount of sepiolite is ultrasonically dispersed in acetic acid solution at 100W for 1h, and then stirred at a stirring speed of 200r / min for 0.5h, wherein the mass ratio of sepiolite to acetic acid is 1:300;

[0054] (3) dissolving CTAB in water at 30°C, wherein the mass ratio of CTAB to water is 9:1000;

[0055] (4) Mix the solutions prepared in steps (1), (2) and (3), and stir at 40°C for 40min;

[0056] (5) Put the solution prepared in step (4) into a polytetrafluoroethylene reactor for solvothermal reaction, the solvothermal temperature is 140° C., and the solvothermal time is 24 hours. Obtain TiO with exposed 001 and 101 crystal planes 2 / Sepiolite Composite Gel.

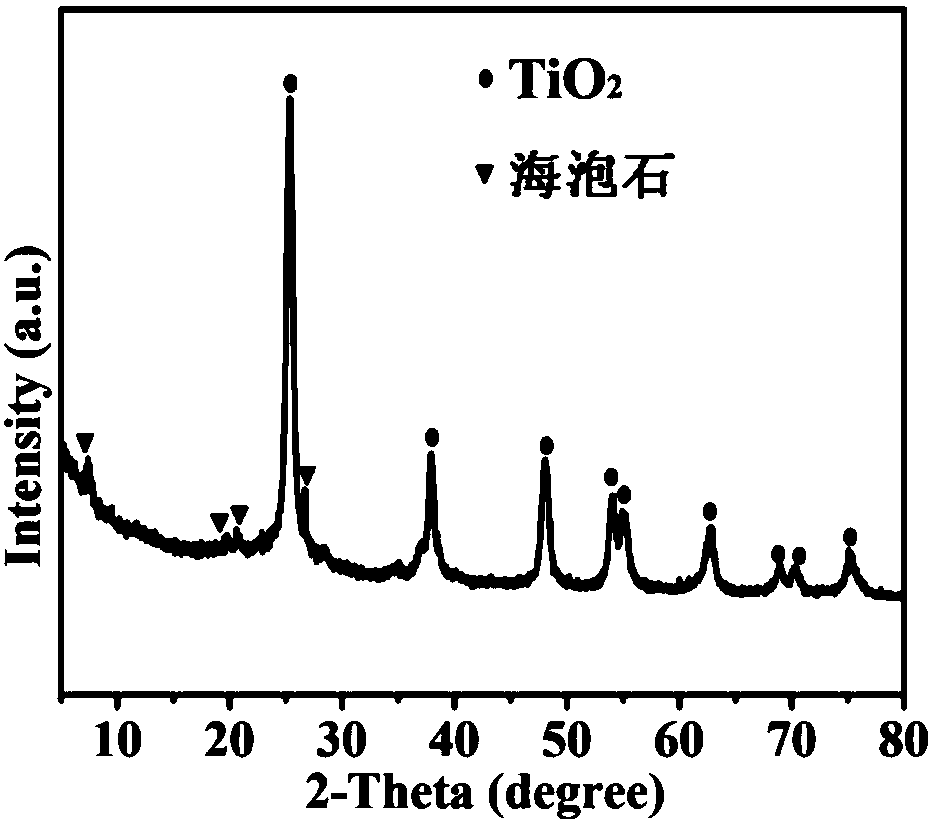

[0057] The T...

Embodiment 2

[0063] (1) Add a certain amount of titanium source into the acetic acid solution, stir and dissolve at 40°C for 24 hours, wherein the mass ratio of titanium to acetic acid is 0.28:40, and the titanium source in this embodiment is tetrabutyl titanate;

[0064] (2) A certain amount of sepiolite is ultrasonically dispersed in acetic acid solution at 100W for 1h, and then stirred at a stirring speed of 200r / min for 0.5h, wherein the mass ratio of sepiolite to acetic acid is 1:300;

[0065] (3) dissolving CTAB in water at 30°C, wherein the mass ratio of CTAB to water is 9:1000;

[0066] (4) Mix the solutions prepared in steps (1), (2) and (3), and stir at 40°C for 40min;

[0067] (5) Put the solution prepared in step (4) into a polytetrafluoroethylene reactor for solvothermal reaction, the solvothermal temperature is 100° C., and the solvothermal time is 24 hours. Obtain TiO with exposed 001 and 101 crystal planes 2 / Sepiolite Composite Gel.

[0068] figure 2 a is the TiO pre...

Embodiment 3

[0070] (1) Add a certain amount of titanium source into the acetic acid solution, stir and dissolve at 40°C for 24 hours, wherein the mass ratio of titanium to acetic acid is 0.28:40, and the titanium source in this embodiment is tetrabutyl titanate;

[0071] (2) A certain amount of sepiolite is ultrasonically dispersed in acetic acid solution at 100W for 1h, and then stirred at a stirring speed of 200r / min for 0.5h, wherein the mass ratio of sepiolite to acetic acid is 1:300;

[0072] (3) dissolving CTAB in water at 30°C, wherein the mass ratio of CTAB to water is 9:1000;

[0073] (4) Mix the solutions prepared in steps (1), (2) and (3), and stir at 40°C for 40min;

[0074] (5) Put the solution prepared in step (4) into a polytetrafluoroethylene reactor for solvothermal reaction, the solvothermal temperature is 160° C., and the solvothermal time is 24 h. Obtain TiO with exposed 001 and 101 crystal planes 2 / Sepiolite Composite Gel.

[0075] The TiO that this embodiment pr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com