Method for adding mesoscopic-scale three-dimensional strengthening phase into metal

A technology of strengthening phase and metal, applied in metal processing equipment, metal material coating technology, additive manufacturing, etc., can solve the problems of easy introduction of impurities, difficulty in improving the distribution state of strengthening phase, low production efficiency, etc. Greatly enhance the toughening effect, the effect of improving the strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] A method for preparing a metal matrix composite material added with a mesoscale three-dimensional strengthening phase, the steps of the method are as follows:

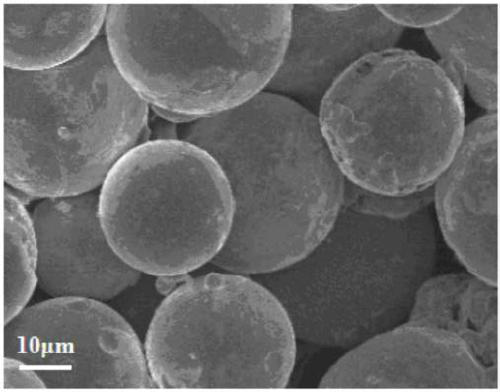

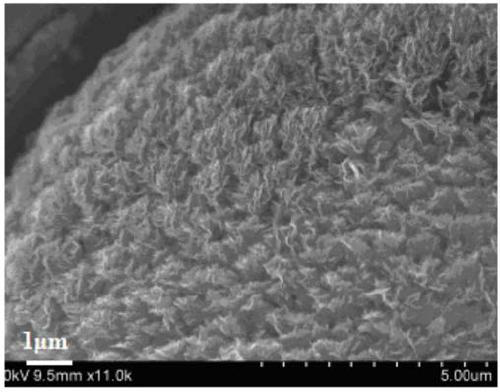

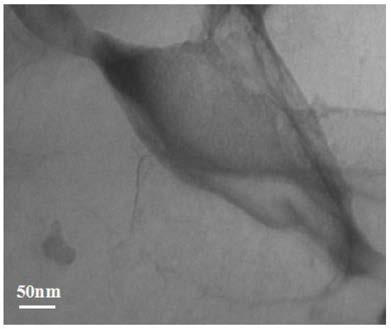

[0027] Step 1. Ultrasonic cleaning and drying of 100 g of nickel-based alloy powder with a powder particle size of 50-200 μm is carried out, and then transferred to a graphite crucible. The chemical composition and weight percentage of the nickel-based alloy are: Cr19.15%, Fe17.95% , Nb5.12%, Mo3.15%, Ti0.97%, Al0.48%, Co≤0.09, C≤0.05, the balance is Ni, the scanning electron microscope photo of nickel-based alloy powder is as follows figure 1 shown. Then put the crucible into the middle of the furnace tube of the plasma chemical vapor deposition vacuum device, and evacuate the device to not less than 1×10 -2 After Pa, methane gas is introduced, the flow rate of methane gas is 30sccm, the pressure in the vacuum speed control device is adjusted to 300Pa, and then the radio frequency source is turned on, the powe...

Embodiment 2

[0034] A method for preparing a metal matrix composite material added with a mesoscale three-dimensional strengthening phase, the steps of the method are as follows:

[0035] Step 1. Ultrasonic cleaning and drying of 100 g of nickel-based alloy powder with a powder particle size of 50-200 μm is carried out, and then transferred to a graphite crucible. The chemical composition and weight percentage of the nickel-based alloy are: Cr19.15%, Fe17.95% , Nb5.12%, Mo3.15%, Ti0.97%, Al0.48%, Co≤0.09, C≤0.05, and the balance is Ni. Then put the crucible into the middle of the furnace tube of the plasma chemical vapor deposition vacuum device, and evacuate the device to not less than 1×10 -2 After Pa, methane gas is introduced, the flow rate of methane gas is 30sccm, the pressure in the vacuum speed control device is adjusted to 300Pa, and then the radio frequency source is turned on. After the deposition, turn off the radio frequency source, stop feeding methane gas, feed argon gas, c...

Embodiment 3

[0040] A method for preparing a metal matrix composite material added with a mesoscale three-dimensional strengthening phase, the steps of the method are as follows:

[0041] Step 1. Ultrasonic cleaning and drying of 100 g of spherical nickel-based alloy powder with a powder particle size of 50-200 μm is carried out and then transferred to a graphite crucible. The chemical composition and weight percentage of the nickel-based alloy are: Cr19.15%, Fe17.95 %, Nb5.12%, Mo3.15%, Ti0.97%, Al0.48%, Co≤0.09, C≤0.05, and the balance is Ni. Then put the crucible into the middle of the furnace tube of the plasma chemical vapor deposition vacuum device, and evacuate the device to not less than 1×10 -2 After Pa, methane gas is introduced, the flow rate of methane gas is 30sccm, the pressure in the vacuum speed control device is adjusted to 300Pa, and then the radio frequency source is turned on, the power of the radio frequency source is 300W, and the temperature is raised to 750°C at the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com