Nano composite toughened oil well cement and preparation method and application thereof

An oil well cement and nano-composite technology, applied in chemical instruments and methods, earth-moving drilling, wellbore/well components, etc., can solve the problems of small water loss, high ultimate compressive strength, low elastic modulus, etc. Small amount of water, improved deformability and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

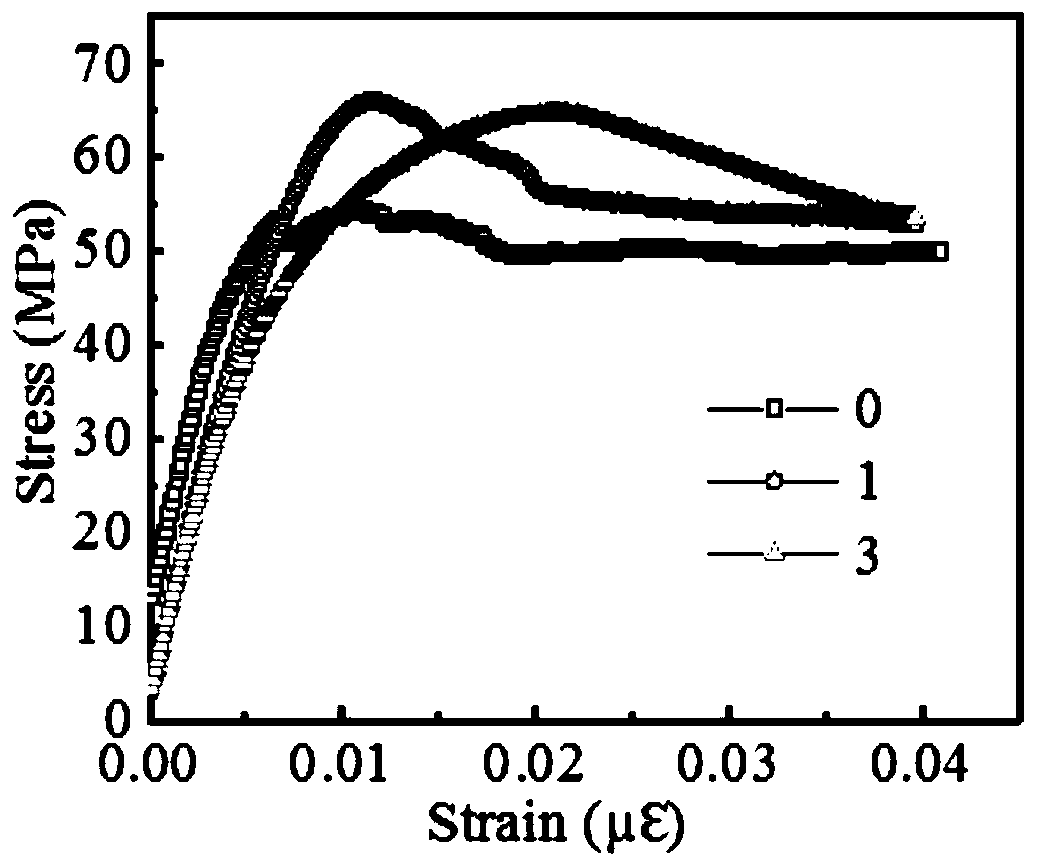

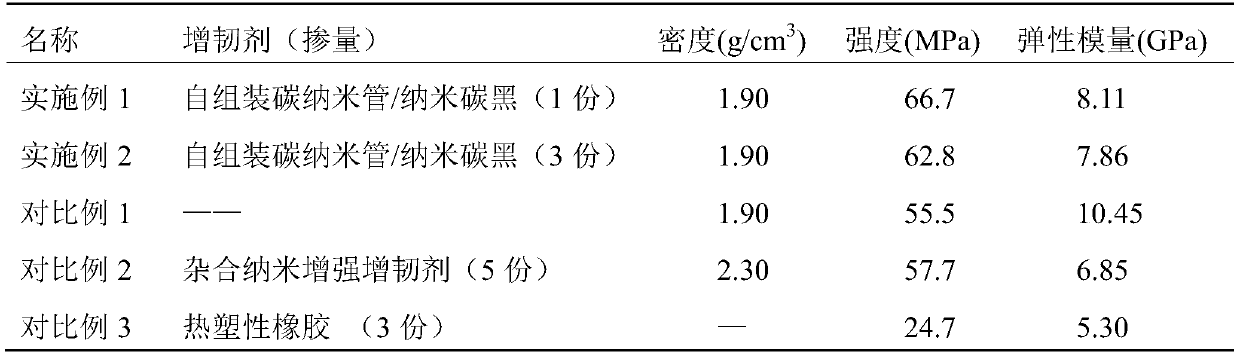

Embodiment 1

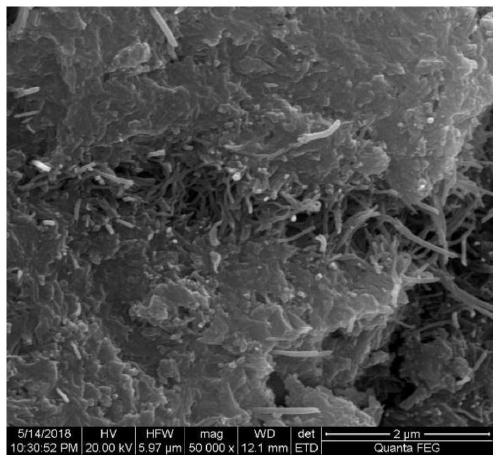

[0028] The present invention uses self-assembled carbon nanotubes / nanocarbon black to toughen and strengthen oil well cement, which can overcome the problem of agglomeration of ordinary nanomaterials in cement, and can also reduce the oil well cement while ensuring that the oil well cement meets the requirements of cementing operations. Its elastic modulus increases its ultimate compressive strength, which can improve the ability of oil well cement sheath to resist cracking under unconventional and complex environmental conditions, and improve the safety and efficiency of oil and gas exploitation.

[0029] In the nanocomposite toughened oil well cement in this embodiment, the raw materials include the following substances in parts by weight:

[0030] 100 parts of cement, 1 part of self-assembled carbon nanotubes / nanometer carbon black, 0.2 parts of dispersant, 0.3 parts of retarder, 0-part of fluid loss reducer, 0.1 part of defoamer and 44 parts of water.

[0031] The self-assem...

Embodiment 2

[0035] In the nanocomposite toughened oil well cement in this embodiment, the raw materials include the following substances in parts by weight:

[0036] 100 parts of cement, 3 parts of self-assembled carbon nanotubes / nanocarbon black, 0.7 parts of dispersant, 0.3 parts of retarder, 0 part of fluid loss reducer, 0.1 part of defoamer and 44 parts of water;

[0037] The self-assembled carbon nanotubes / nanocarbon blacks are prepared by an electrostatic self-assembly process, presenting a grape cluster structure, wherein the weight ratio of carbon nanotubes to nanocarbon blacks is 40:60, and the specific surface area is 65-75m 2 / g, the density is 2.0g / cm 3 , the outer diameter of carbon nanotubes is greater than 50nm, the length of carbon nanotubes is 10-20μm, and the specific surface area of carbon nanotubes is greater than 40m 2 / g, the particle diameter of nano-carbon black is 23nm, and the specific surface area of nano-carbon black is 23m 2 / g.

[0038] Mixing process:...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com