Fluorescent sheet for white light illumination source generated by laser excitation and preparation method thereof

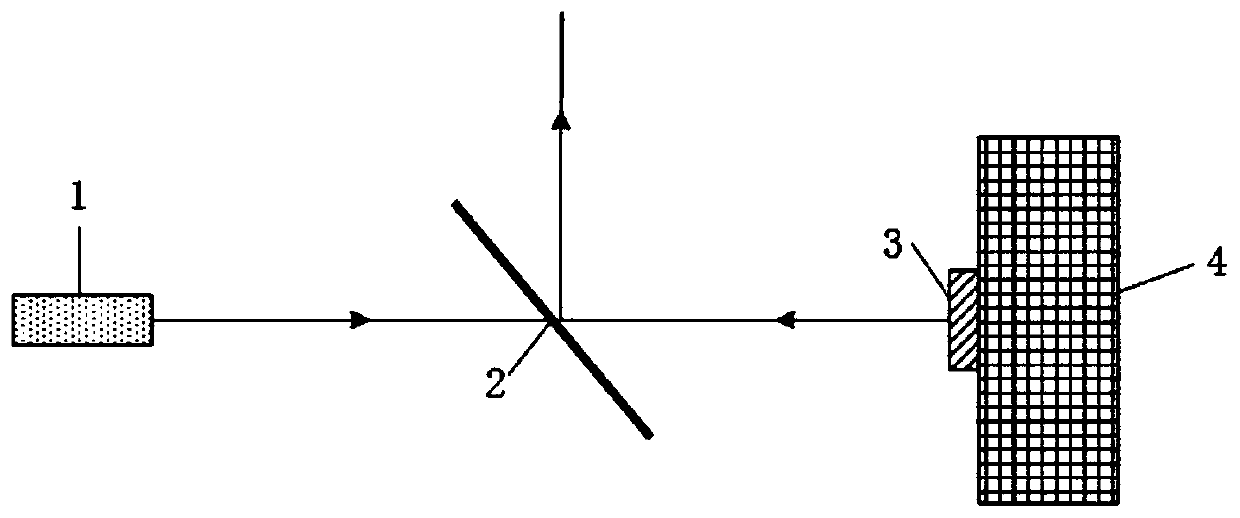

A lighting source and fluorescent sheet technology, which is applied in lighting and heating equipment, light sources, and optical elements used to change the spectral characteristics of emitted light, etc., can solve the problems of large divergence angle and low brightness of white light, and achieve high brightness and directional Good performance and small divergence angle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

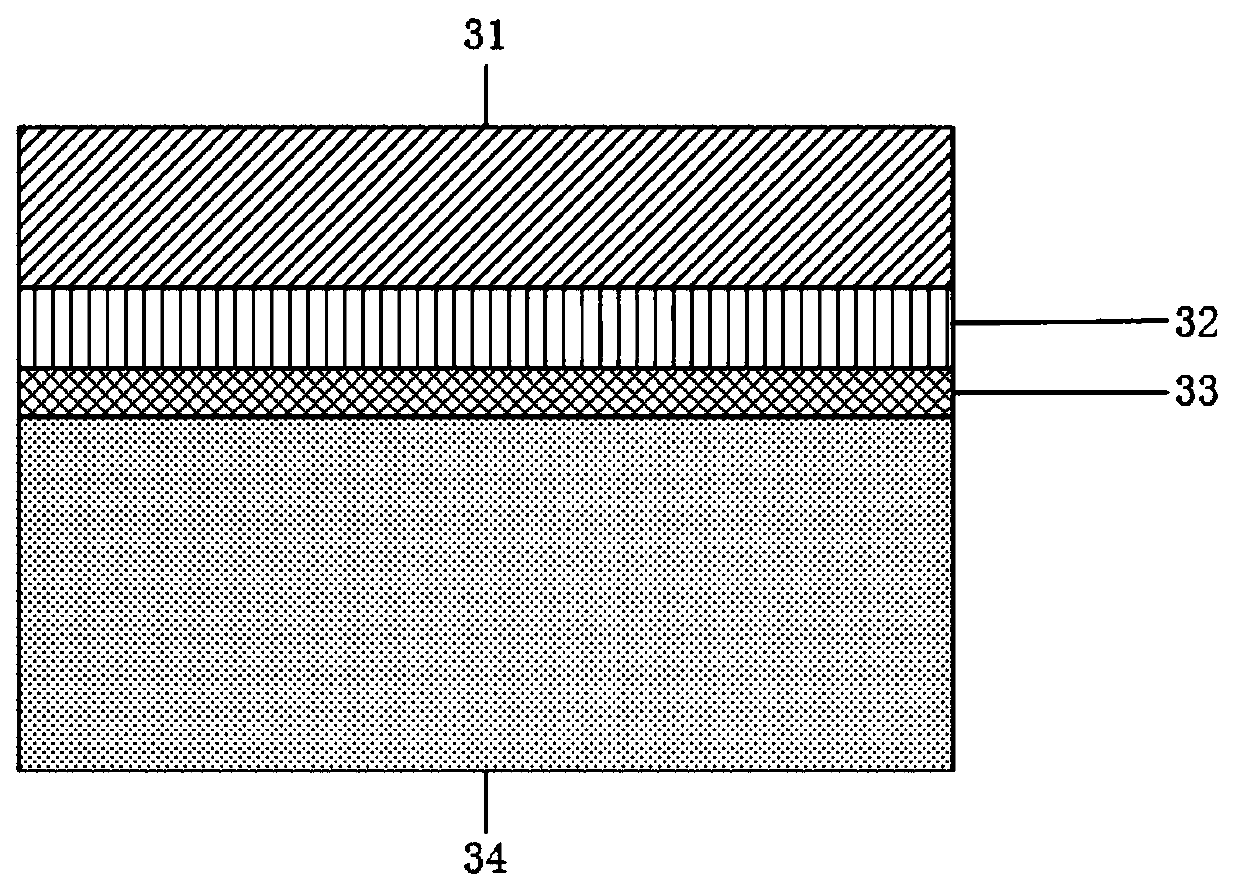

[0040] The embodiment of the present invention also provides a method for preparing the above-mentioned fluorescent sheet for generating white light by laser excitation, including the following steps:

[0041] (1) Cutting the material of the substrate layer 34 whose surface is covered with the metal specular reflection layer 33 into square pieces, cleaning and drying.

[0042] The material of the substrate layer 34 with the metal specular reflection layer 33 on the surface can be directly purchased or made by oneself, and the specific manufacturing method is as follows: when the metal specular reflection layer 33 and the substrate layer 34 are made of the same metal material, the substrate layer 34 can be After the surface is polished to meet the vacuum coating mirror standard, the metal mirror reflection layer 33 can be obtained; when the metal mirror reflection layer 33 and the base material layer 34 are made of different materials, a vacuum coating method can be used, and th...

Embodiment 1

[0053] (1) Purchase a 0.5 mm thick silicon wafer covered with a mirror-reflective gold film, cut into 20 mm by 20 mm squares as the metal reflection layer and high thermal conductivity substrate layer, clean, dry, and set aside.

[0054] (2) Evenly mix the thermosetting glue and yellow YAG fluorescent powder to obtain fluorescent glue, then spin-coat the fluorescent glue on the silicon wafer, heat and cure to obtain fluorescent glue layer 1, and the thickness after curing is 5 microns, the fluorescent glue layer One thickness is half of the thickness of the designed fluorescent adhesive layer.

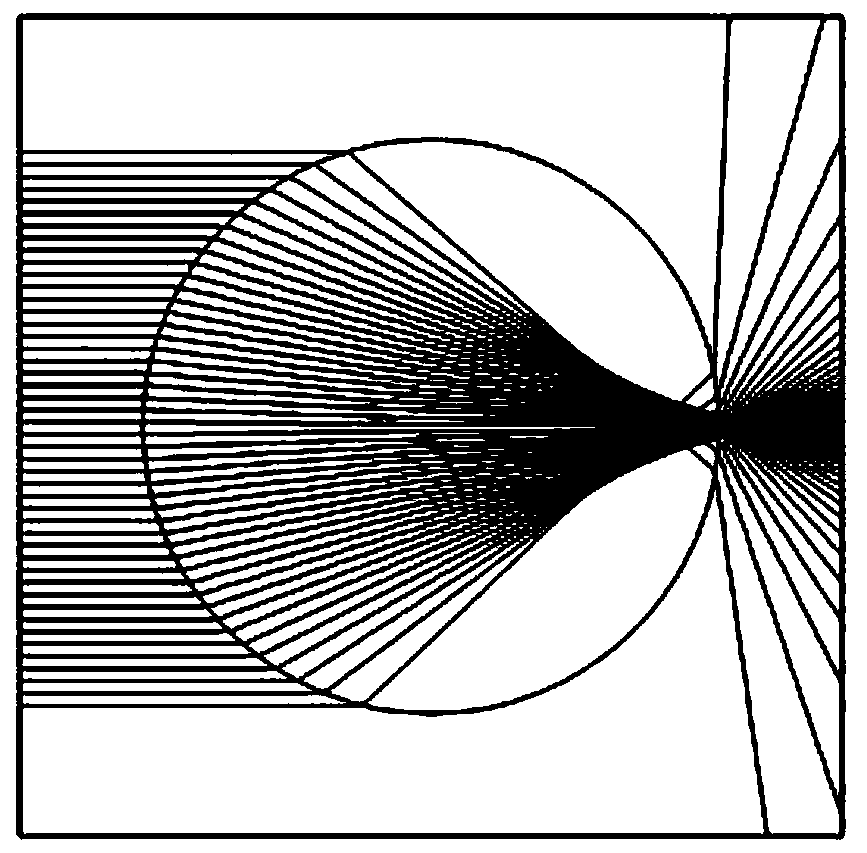

[0055] (3) Purchasing Pb-Na-Si glass phase microspheres with a refractive index of 1.9 and a diameter of 200 microns, cleaned, dried, and set aside.

[0056] (4) Obtain a uniformly arranged single-layer microsphere layer by vibrating and extruding on a horizontal plate, and the microspheres are arranged in a single layer without defects through a microscope visual inspection.

[0057]...

Embodiment 2

[0059] (1) Purchase 2mm thick aluminum sheet, cut into 20mm by 20mm square piece, polish it into a mirror surface, degrease, clean, dry, and set aside, the polished and cut square aluminum piece is also the metal reflective layer and High thermal conductivity substrate layer.

[0060] (2) Evenly mix the heat-curing glue with yellow TAG phosphor powder and green aluminate phosphor powder to obtain fluorescent glue, then spin-coat the fluorescent glue on the polished surface of the aluminum sheet, heat and cure it, and obtain a fluorescent glue with a thickness of 2 microns layer one.

[0061] (3) Purchase Ti-Bi-Be glass phase microspheres with a refractive index of 2.2 and a diameter of 40 microns, wash, dry, and set aside.

[0062] (4) Fill the bottom surface of the container with a single layer of microspheres, disperse the microspheres that are filled with a single layer of the bottom surface of the container in the water phase, use an ultrasonic cleaning machine to achieve...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com