Ferrite heat resistant steel

A ferritic and heat-resistant steel technology, applied in the field of ferritic heat-resistant steel, can solve the problems of insufficient high strength and insufficient resistance to welding cracks.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

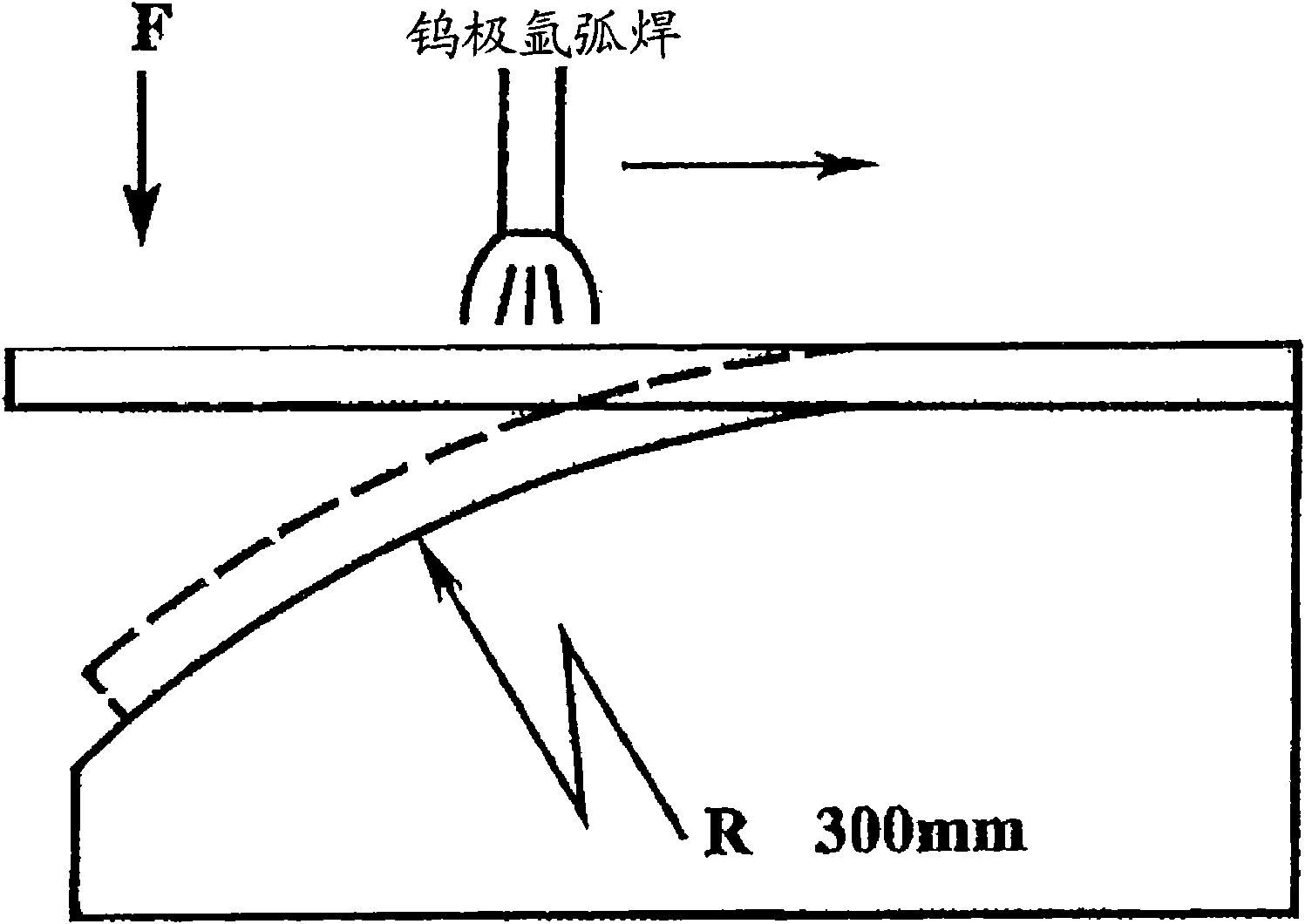

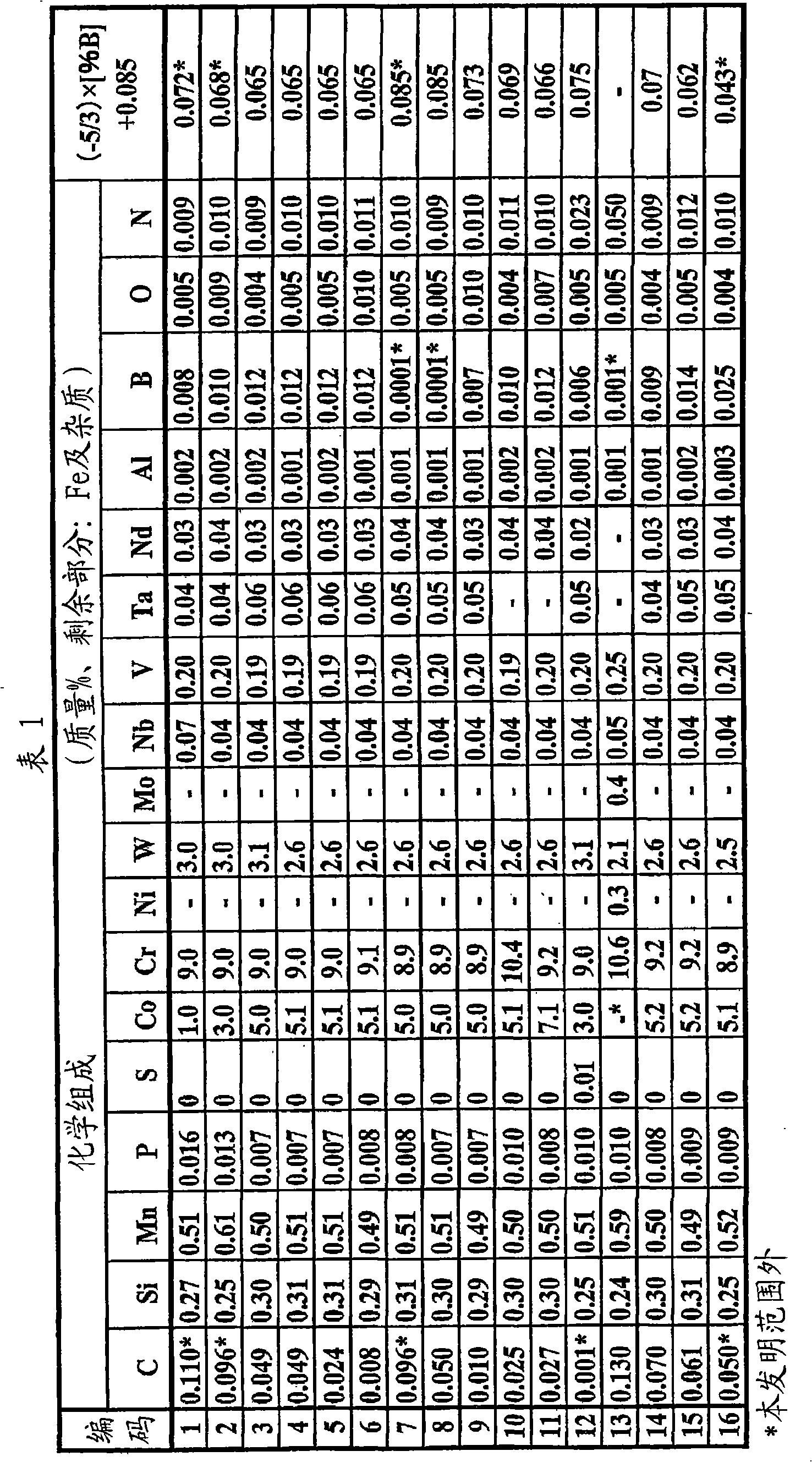

[0082] 16 kinds of steels having the chemical compositions shown in Table 1 were melted in a vacuum melting furnace, and after forging and rolling, air cooling was performed after holding at 1150°C for 1 hour and air cooling after holding at 770°C for 1.5 hours Tempering heat treatment. In addition, code 13 corresponds to the steel of SUS410J3TB which is a general-purpose steel, and is used as a comparative steel concerning creep strength. Furthermore, a steel plate having a thickness of 12 mm, a width of 50 mm, and a length of 300 mm, and a steel plate having a thickness of 10 mm, a width of 100 to 120 mm, and a length of 300 to 500 mm were produced by machining. A steel plate with a thickness of 12mm is used for longitudinal adjustable restraint crack test to evaluate the liquefaction crack susceptibility of HAZ.

[0083] [Table 1]

[0084]

[0085] Such as figure 1 As shown in the schematic diagram of , the longitudinal adjustable restraint crack test is such a method...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com