Coherent jet oxygen blowing method for electric furnace steel making

An electric furnace steelmaking and jet technology, applied in the field of oxygen blowing in steelmaking, can solve the problems of damage to the burner, strengthen the stirring of the molten pool, etc., and achieve the effects of reducing power consumption, strengthening the oxygen-enriching operation, and enhancing the dephosphorization effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

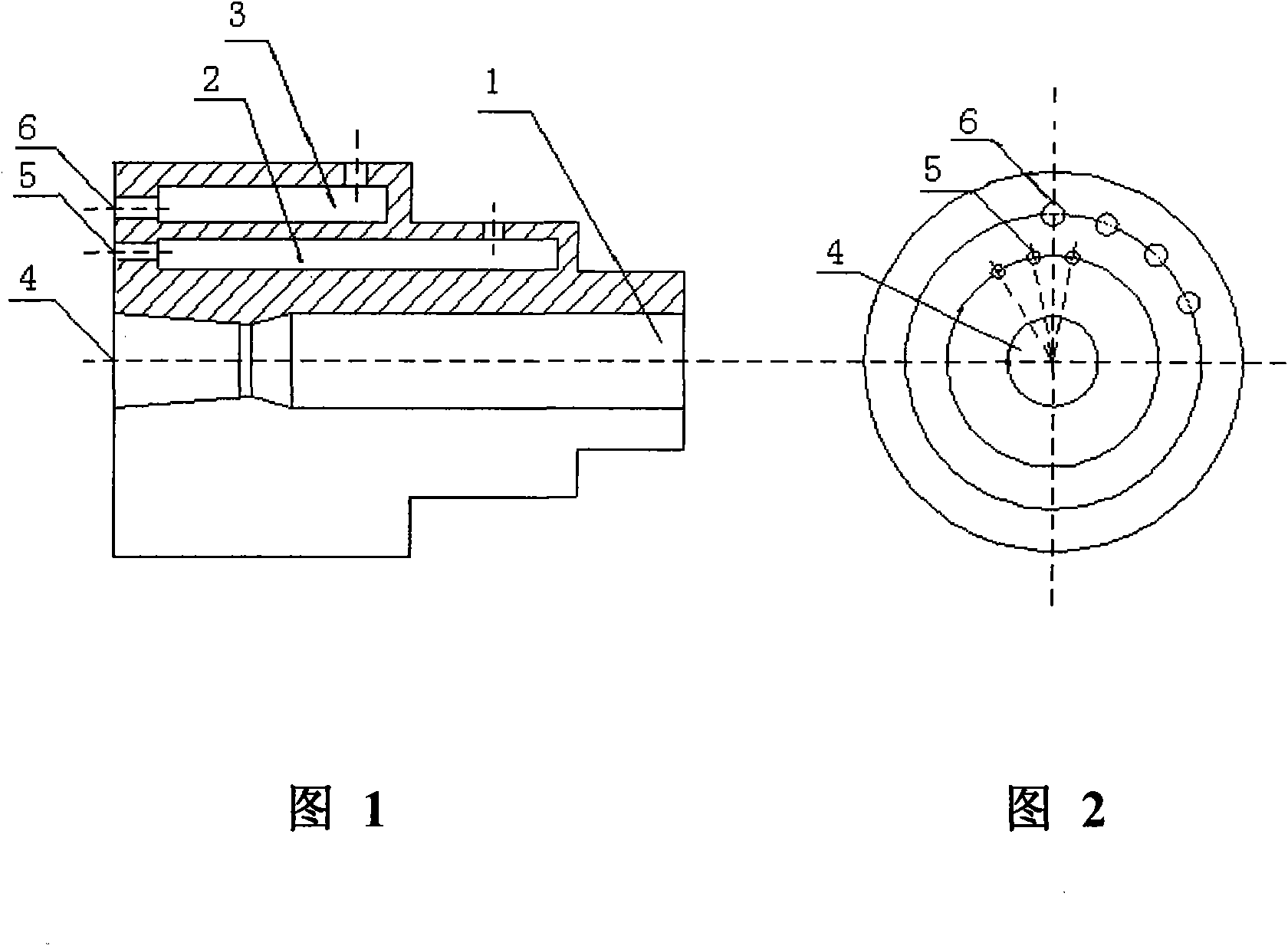

[0015] Electric furnace steelmaking polymerization jet oxygen blowing method, including selection of polymerization jet oxygen blowing device and polymerization jet oxygen blowing process conditions, such as figure 1 , figure 2 As shown, the polymerization jet oxygen blowing device is composed of three parts: the main oxygen injection system 1, the auxiliary oxygen injection system 3, and the gas injection system 2. The main oxygen injection system is located in the center of the polymerization jet oxygen blowing device; the gas injection system is located on the outer layer of the main oxygen injection system; the auxiliary oxygen injection system is located on the outer layer of the gas injection system. The nozzle structure of the polymerization jet oxygen blowing device is composed of one main oxygen injection hole 4, sixteen gas injection holes 5 and sixteen auxiliary oxygen injection holes 6. Gas injection holes and auxiliary oxygen injection holes are arranged alterna...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com