Rotating type double-body compressor

A compressor and rotary technology, which is applied in the field of rotary double-body compressors, can solve the problems of large number of parts, long assembly time, and low reliability, and achieve the goals of simplifying the assembly process, reducing refrigerant leakage, and improving production efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] Below, the present invention will be described in further detail in conjunction with the accompanying drawings and specific embodiments.

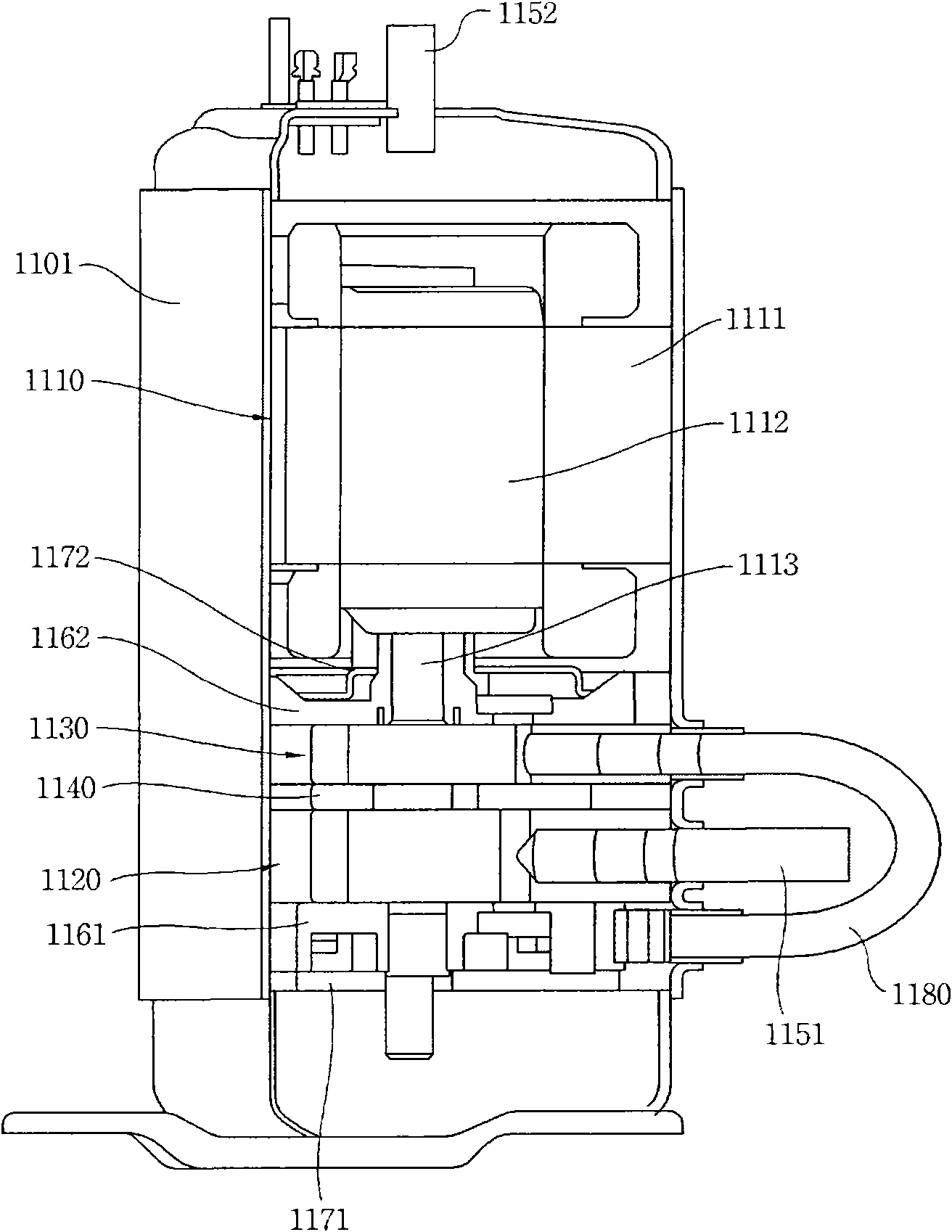

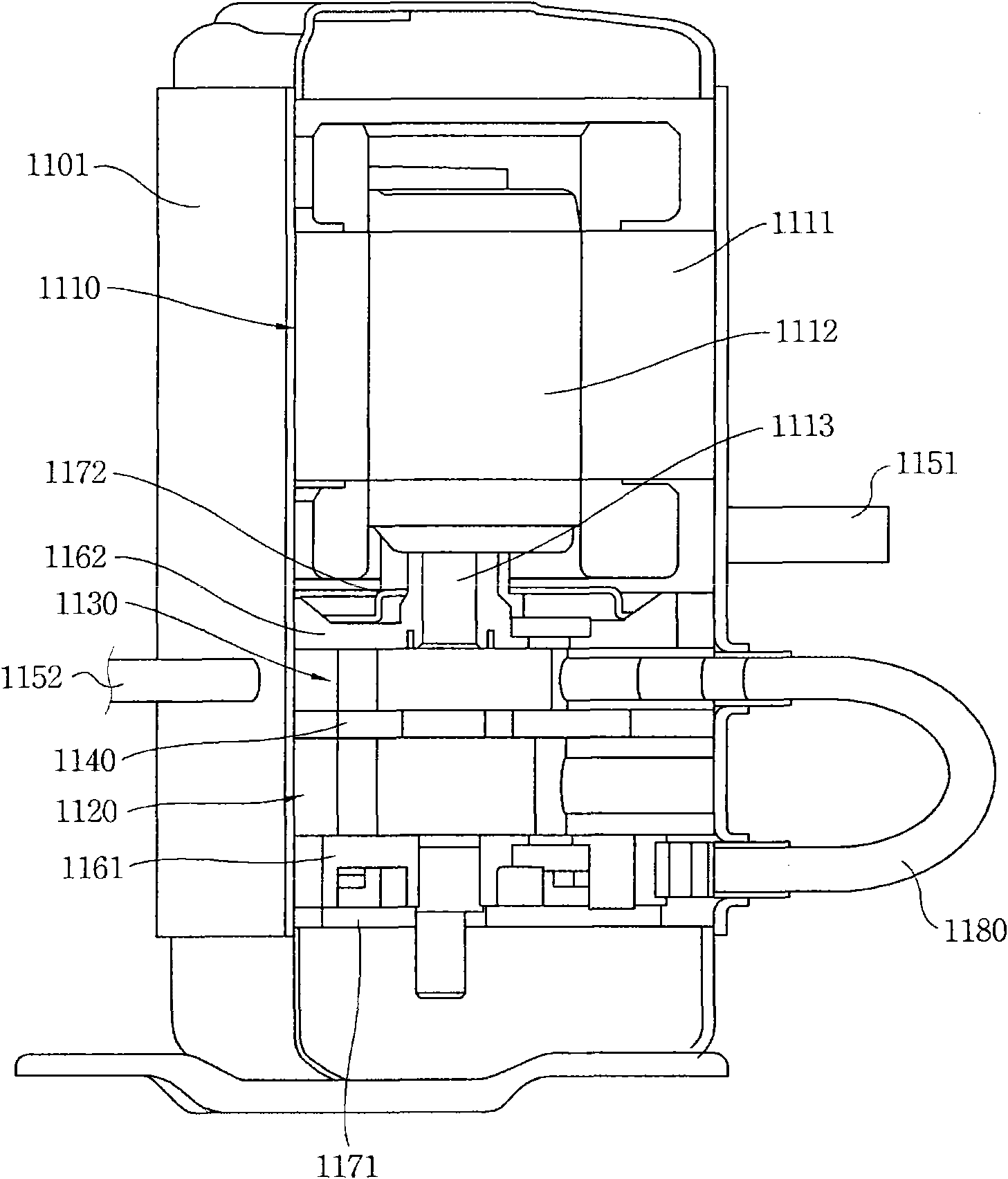

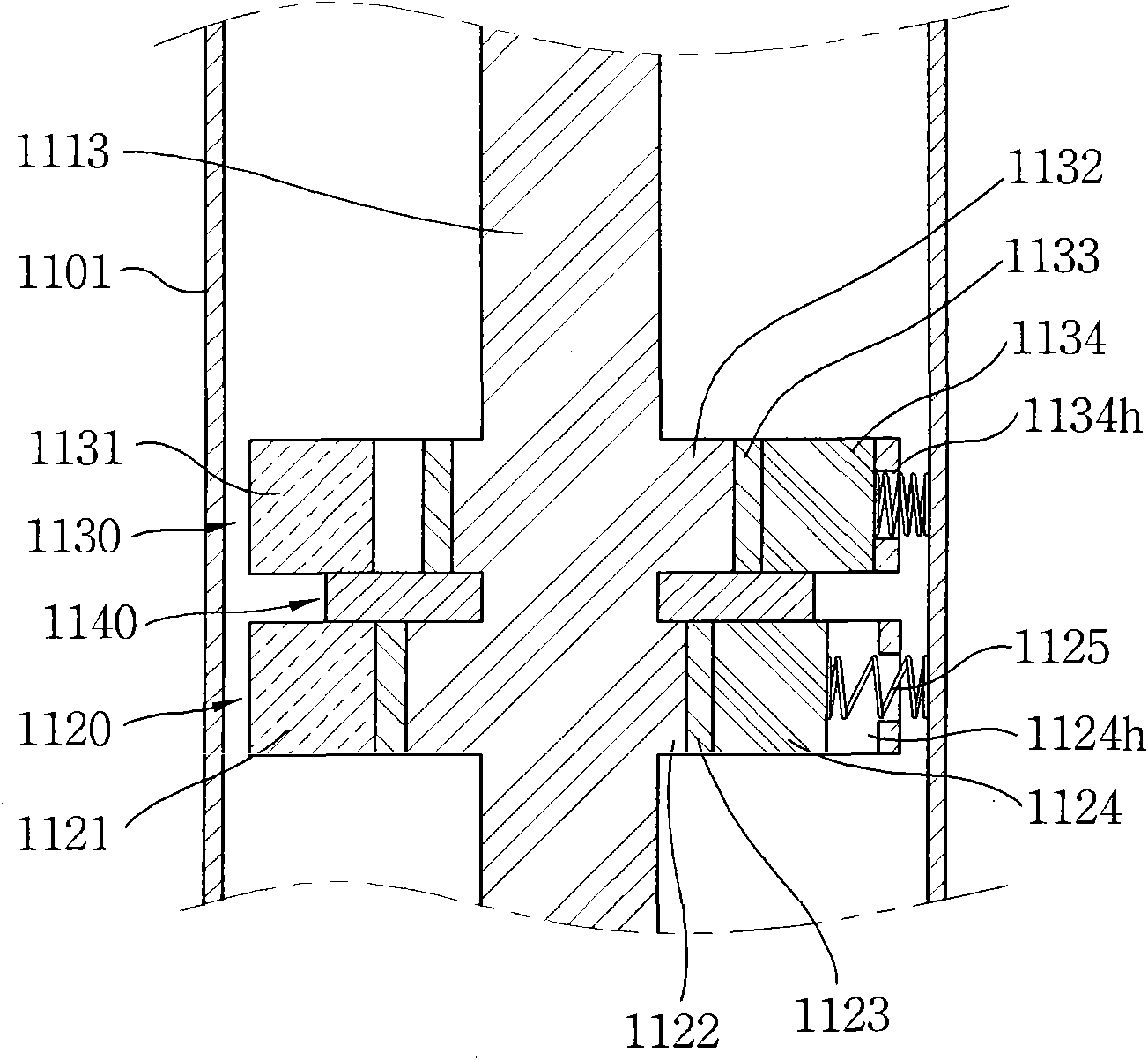

[0034] Figure 4 It is a schematic diagram of an embodiment of the rotary dual-body compressor of the present invention. Such as Figure 4As shown, the rotary double-body compressor of the present invention includes a closed container 101, a motor 110 that generates rotational force, a first compression assembly 120 that compresses a part of the sucked refrigerant, and a second compression unit 120 that compresses the rest of the sucked refrigerant. The assembly 130 divides the middle plate 140 of the first and second compression assemblies 120, 130, constitutes the first bearing 161 and the cover 171 communicating with the first discharge space on the lower side of the first compression assembly 120, and constitutes the first bearing 161 and the cover 171 communicating with the second discharge space. The second bearing 162 and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com