High temperature thermal cutoff device

A warm, fusing technology, used in circuit devices, automatic disconnection emergency protection devices, emergency protection devices, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

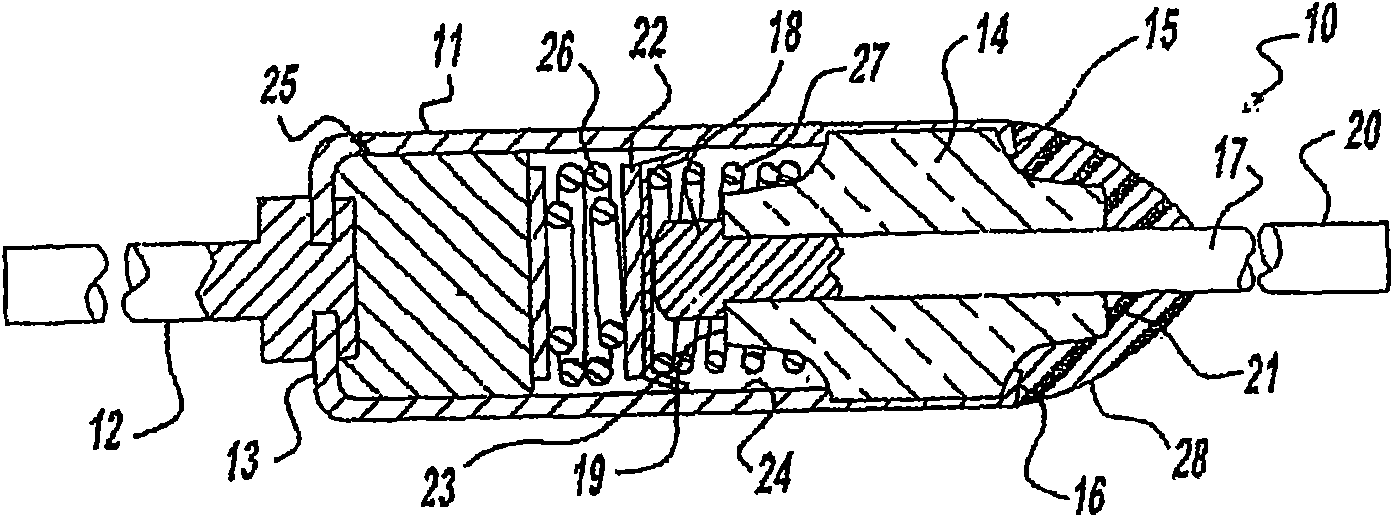

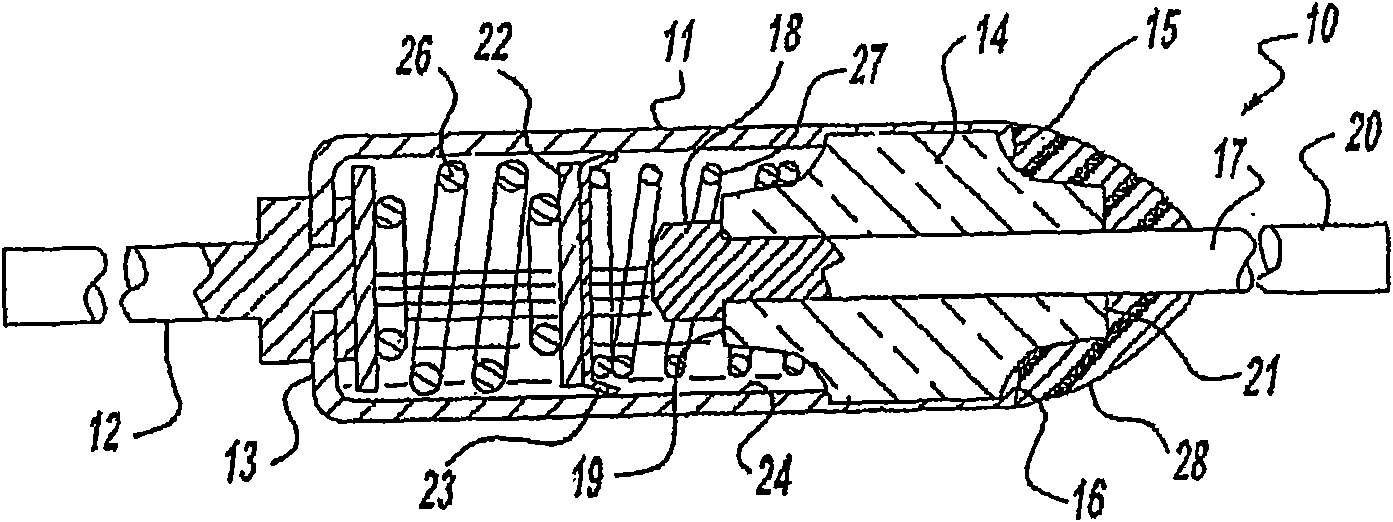

[0076] According to various aspects of the invention, a high temperature TCO device is formed as follows. Thermal pellets are formed by combining 980 g to 1000 g of triptycene (commercially available from Sigma-Aldrich manufacturer, 95-99% pure) with 20 g to 0.5 g of colorant, binder and / or mold release agent mix. The homogenized mixture was processed on a standard powder compaction press (commonly available from pharmaceutical equipment suppliers). Powder is fed through a gated powder flow control system and evenly distributed over the rotating die table. The mold is filled with the powder and the powder in the mold is punched under a pressure of about 1 to 4 tons to form compacted powder pellets having a density of 29 to 50 pellets / gram. The thermal pellets were placed into a highly conductive metal closed-end cylinder with an inner diameter close to the outer diameter of the TCO thermal pellets. The closed end of the barrel is staked shut with axial conductive metal lead...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com