Process for biostabilization and humification of biological sludge in planted filtering beds

A technology of biological sludge and stabilization method, applied in chemical instruments and methods, biological water/sewage treatment, sustainable biological treatment, etc., can solve the problems of liquid accumulation and low efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0084] In the purification plant where the measurements were made, the amount of sludge produced by 3,000 equivalent inhabitant (e.i.) was treated, which generated about 1,200m 3 / year (2% solids) of biological sludge.

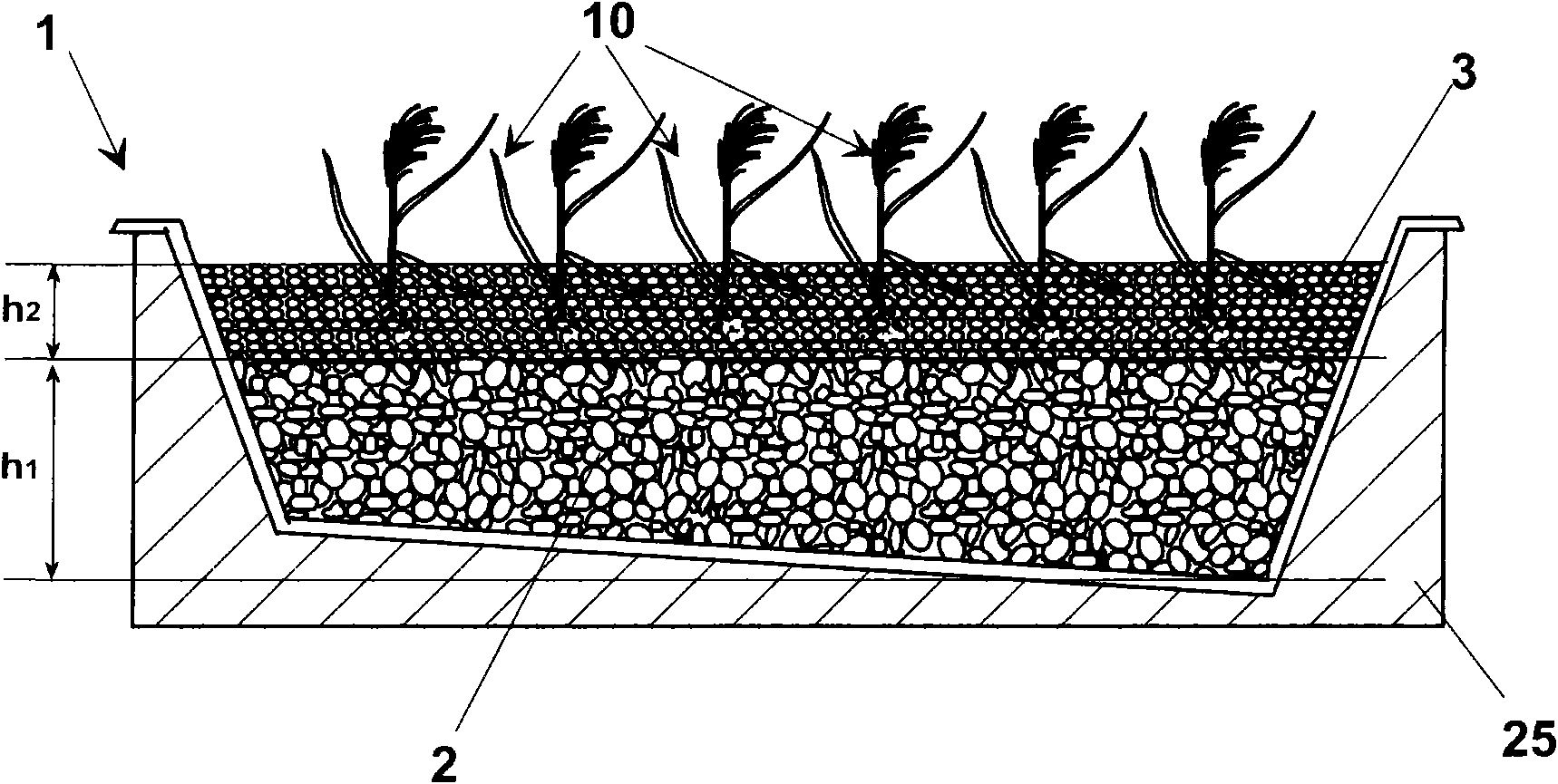

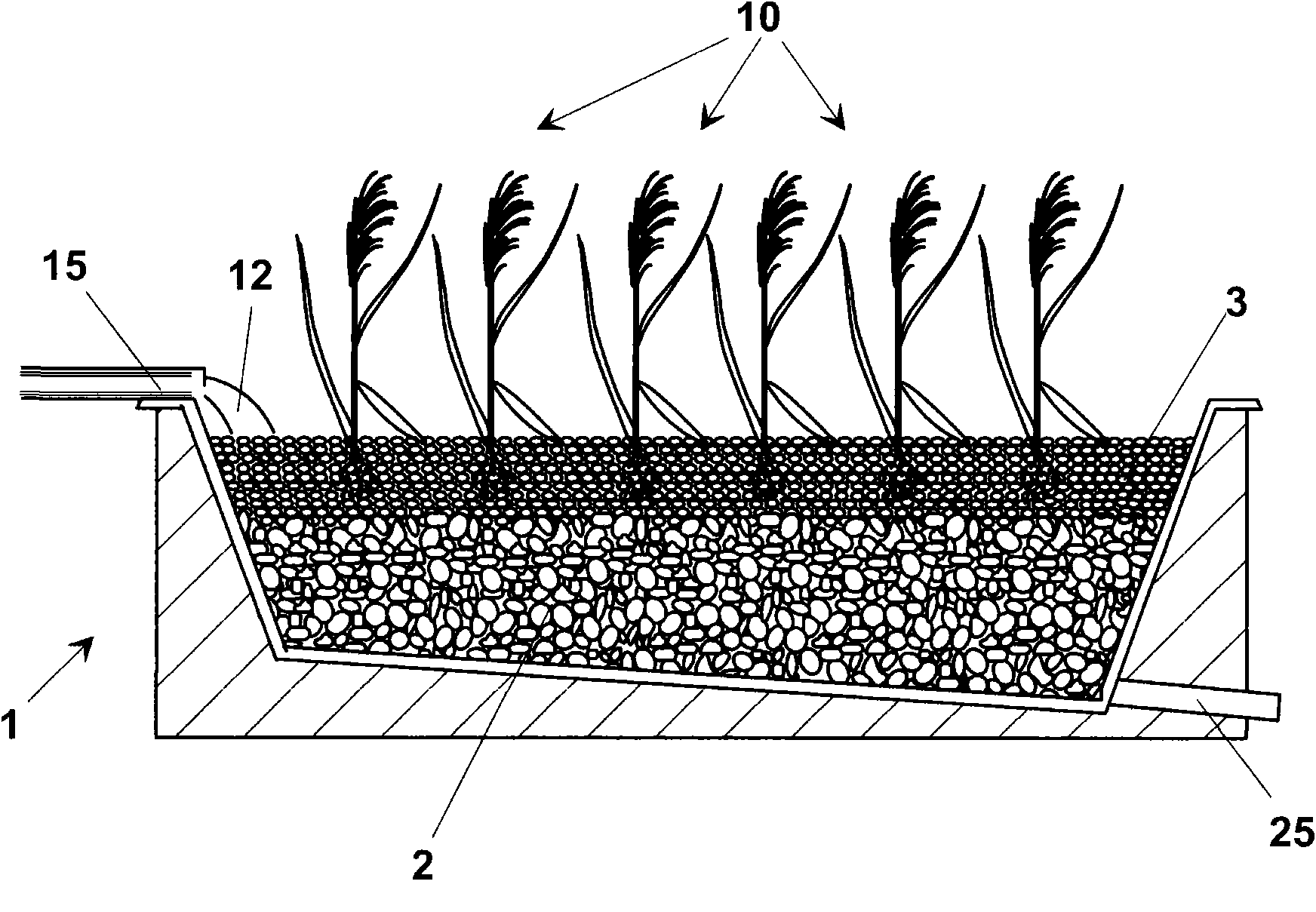

[0085] For the phytostabilization method, a size of 10m x 2.5m x 0.7m with a capacity of 17.5m was used 3 six sludge drying beds. Of these beds, only 4 were used for experiments, while the remaining two were left unused and kept in reserve for possible plant emergencies. The bottom layer of the plant drying bed consisted of drainage material (25 cm of gravel with a diameter of 40-70 mm and 15 cm of gravel with a diameter of 0.5 cm) in which perforated conduits were placed for collecting leachate.

[0086] In May 2004, reed seedlings were placed in an intermediate layer between larger gravel and smaller gravel in the number of about 140 per basin. In order to ensure the development and growth of the plants, fresh water followed by nutrient-rich water from a ...

Embodiment 2

[0089] Prepared with a total volume of 864m 3 12 drying ponds. For a total of 6652m generated in the method 3 Sludge (30000e.i.) used about 4,500m per year 3 sludge.

[0090] The step of planting seedlings in the bed was carried out at the end of July, 2005, and the occupied area of each plant was 0.5m×0.5m. After a period of about one month for the seedlings to acclimatize and grow, to which they were supplied with water from the plant to reduce stress from transplanting and to help better rooting, the first layer of sludge was poured in September 2005, The first samples were then taken in early October 2005 and the plant continued to operate. During the first year of operation, the volume of sludge was reduced by 99% at a rate of 2.42 cubic meters per square meter.

Embodiment 3

[0092] Identical with embodiment 2, its difference is that preparing total volume is 225m 3 of 5 drying pools. For a total of 5616m generated in the method 3 Sludge (10000e.i.) uses about 1462m per year 3 sludge. During the first year of operation, the volume of sludge poured was reduced to 98% at a rate of 3.16 cubic meters per square meter.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com