Automatic production device in valve pressure forging process

A technology of automatic production and hot die forging, applied in forging/pressing/hammer devices, forging presses, forging presses, etc., can solve the problem of increased labor intensity of production workers, slowed down of production workers, and impact on the health of production workers, etc. problems, to achieve stable and reliable working process, reduce the harm of noise to the human body, and low cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

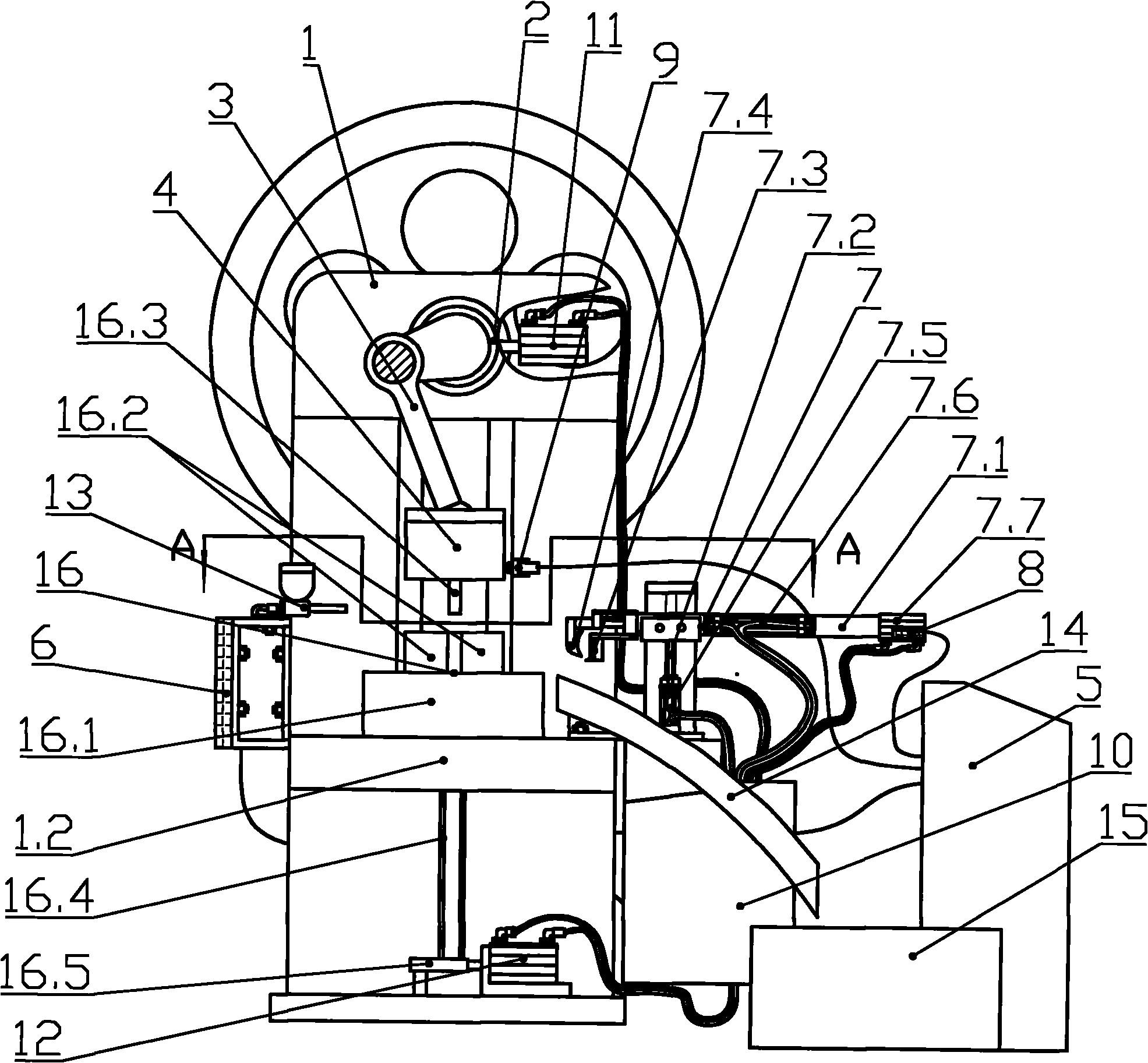

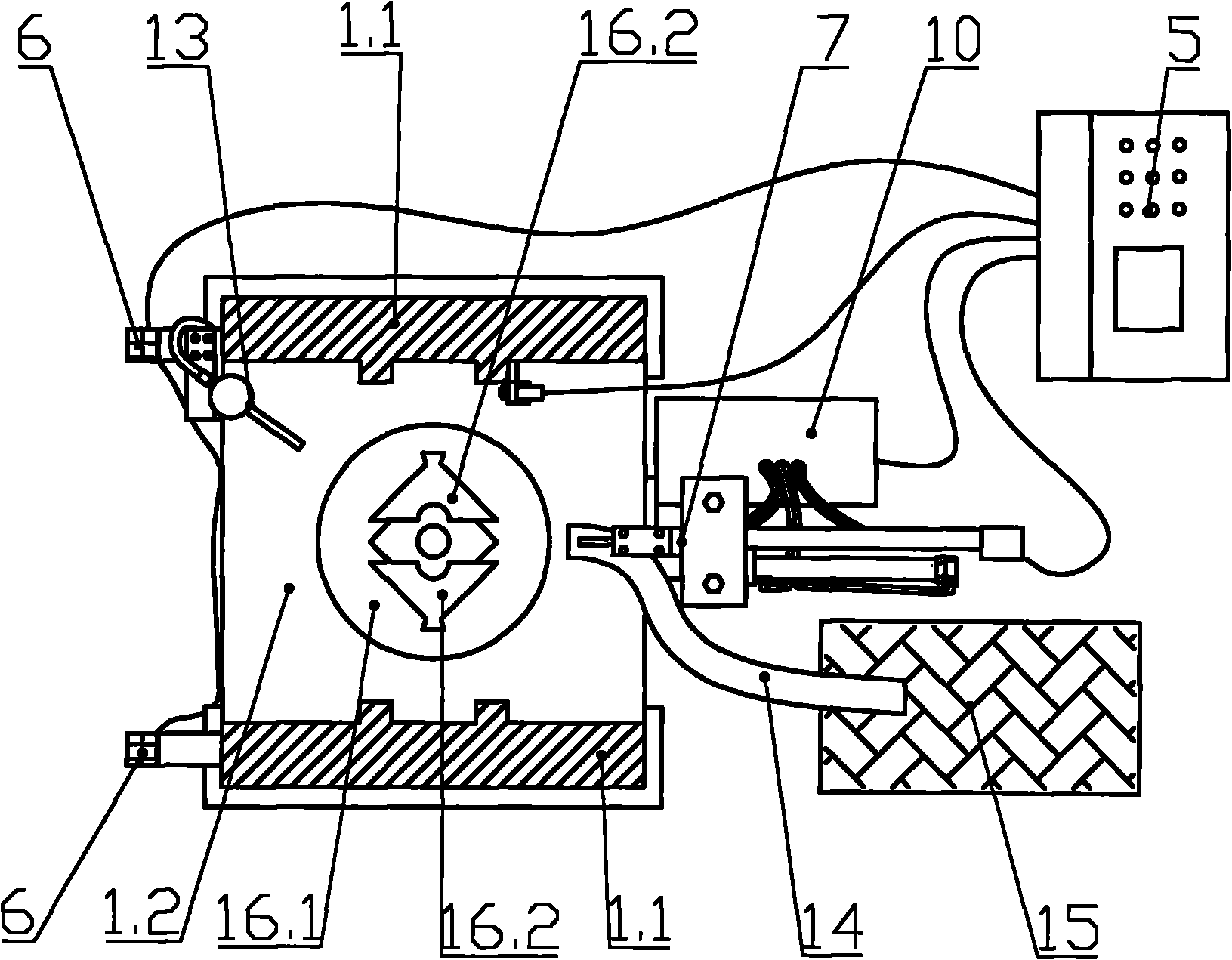

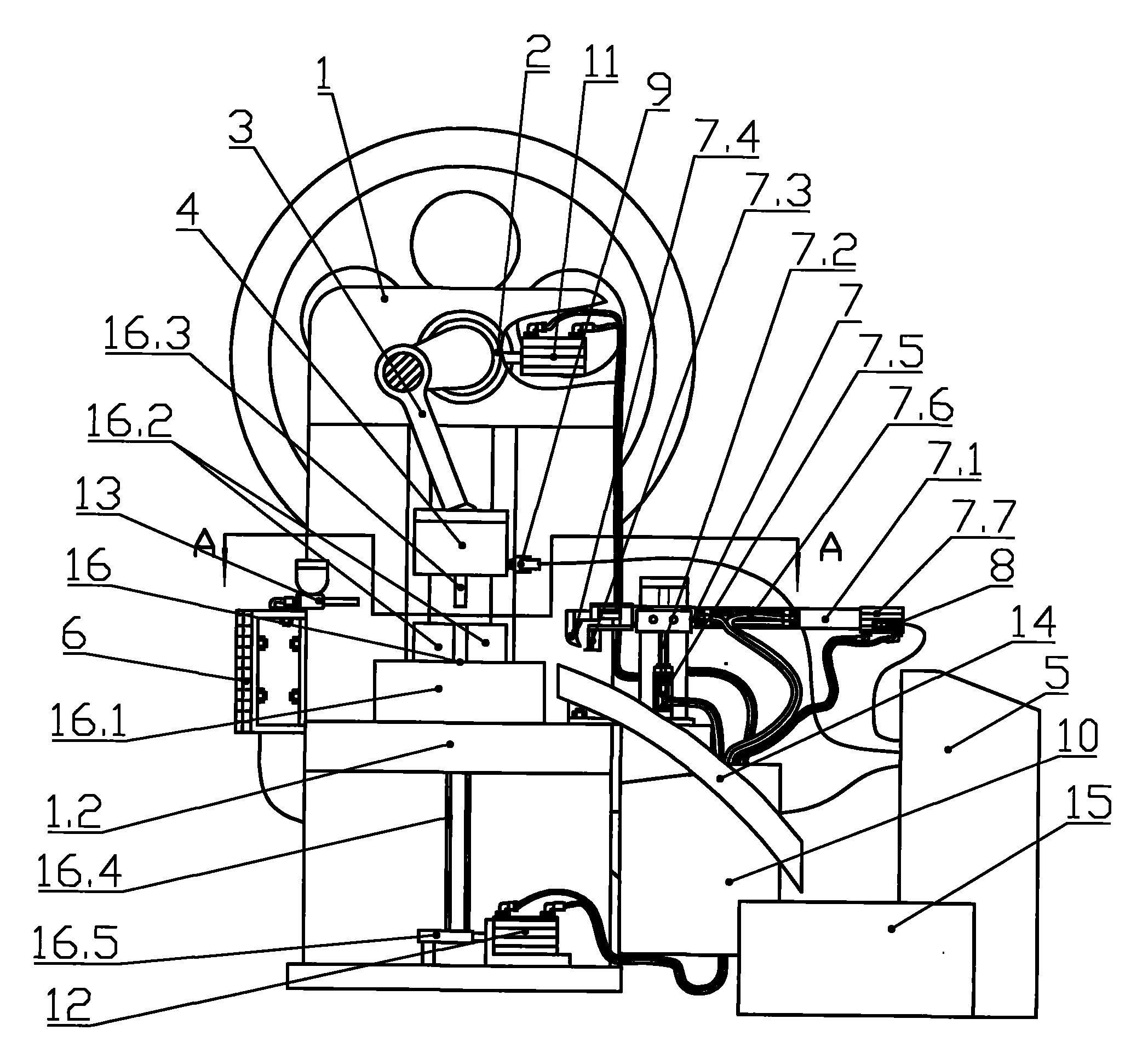

[0022] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0023] Such as figure 1 , figure 2 As shown, the automatic production device of the valve hot die forging process of the present invention includes a press 1 and a hot forging die 16; The slider 4, the clutch 2 and the connecting rod 3 installed on the upper end of the press 1; one end of the connecting rod 3 is connected with the slider 4, and the other end is connected with the crankshaft of the clutch 2; the hot forging die 16 includes a The forming punch 16.3 at the lower end of the slider 4, the lower mold base 16.1 installed on the press table 1.2, the Huff mold core 16.2 installed on the lower mold base 16.1, and the ejector stopper 16.5 arranged at the bottom of the press 1 1. The ejector pin 16.4 arranged on the upper end surface of the ejector pin block 16.5 to separate or reset the half mold core 16.2; the half mold core 16.2 is d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com