Purifying and recovering process of absolute dry bag-type converter gas negative energy

A converter gas, dry bag technology, applied in the improvement of process efficiency, furnaces, incinerators, etc., can solve the problems of easy corrosion of electrostatic precipitator plates, failure to recover heat, and high moisture content in gas, reducing system Control elements, large amount of recovery, and high calorific value of gas recovery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

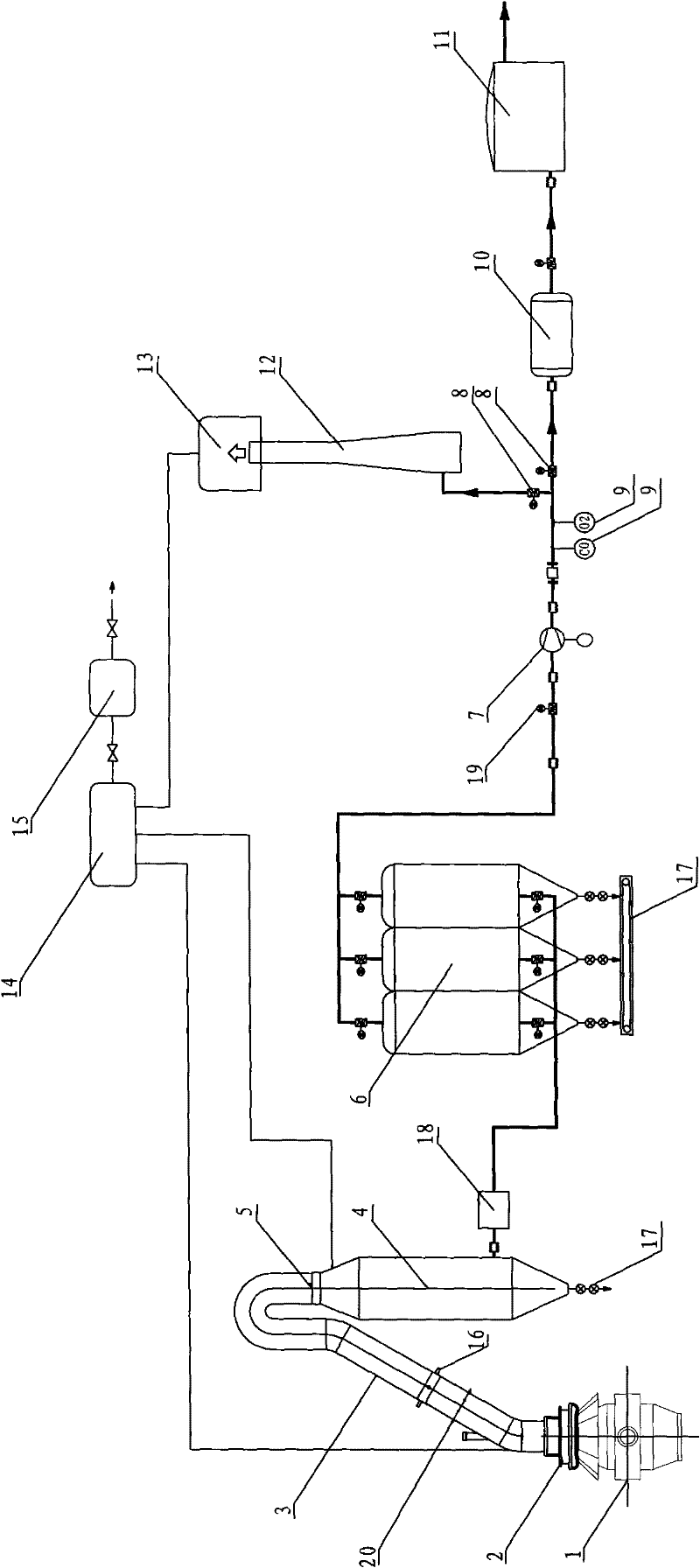

[0022] A full-dry bag-type converter gas negative energy purification and recovery process, such as figure 1 As shown, the process steps are as follows:

[0023] The first step: gas capture: the raw gas in the furnace generated during the smelting process of the converter 1 is captured through the movable hood port 2 set above the furnace port;

[0024] Step 2: Coal gas cooling and waste heat recovery in the high temperature section: After the 1450°C gas captured by the movable hood port 2 enters the vaporization cooling flue 3 connected to the movable hood port 2, it is cooled to 900°C, while recovering the generated saturated steam, install a combustible gas explosion suppression device 16 for the flue in the middle section of the vaporization cooling flue 3 to reduce the oxygen content of the gas in the pre-burning and post-burning stages;

[0025] Step 3: Coal gas cooling and coarse dust removal in the middle and low temperature section: a tube bundle heat exchanger 4 is ...

Embodiment 2

[0030] A full-dry bag-type converter gas negative energy purification and recovery process, such as figure 1 As shown, the process steps are as follows:

[0031] The first step: gas capture: the raw gas in the furnace generated during the smelting process of the converter 1 is captured through the movable hood port 2 set above the furnace port;

[0032] Step 2: After the gas at 1650°C captured by the movable hood 2 enters the vaporization cooling flue 3 connected to the movable hood 2, it cools down to 1000°C through the heat exchange between the partition walls of the soda and water, and at the same time generates saturated steam with a pressure of 2.4MPa As a by-product of this process link, a combustible gas explosion suppression device 16 for the flue is installed in the middle section of the vaporization cooling flue 3 to reduce the oxygen content of the gas in the pre-burning and post-burning stages, prolong the recovery period and reduce the probability of gas explosion...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com