A controllable ultra-high flow rate and large flow water tunnel system and control method

A large flow, ultra-high-speed technology, applied in the field of experimental fluid mechanics, can solve the problems of reduced performance, poor reliability, and difficult implementation of water pump equipment, and achieve the effects of reducing power supply, reducing construction costs, and improving compression efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be further described in detail below in conjunction with specific embodiments, which are explanations of the present invention rather than limitations.

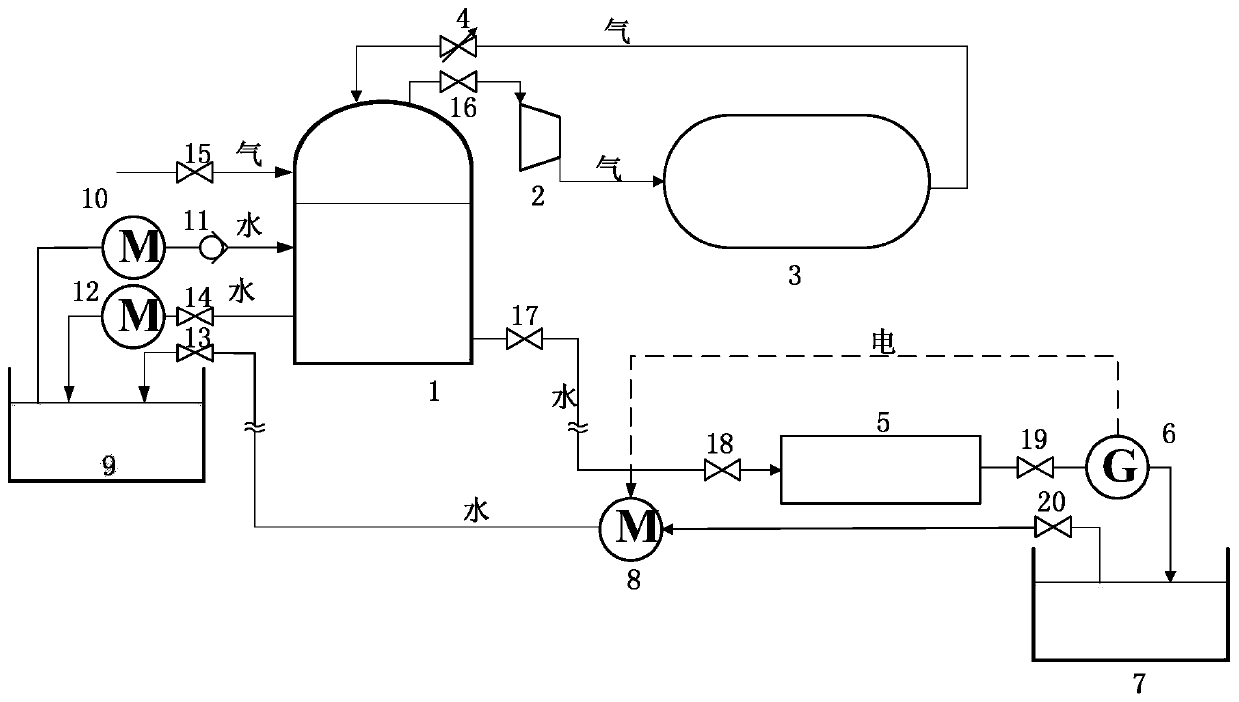

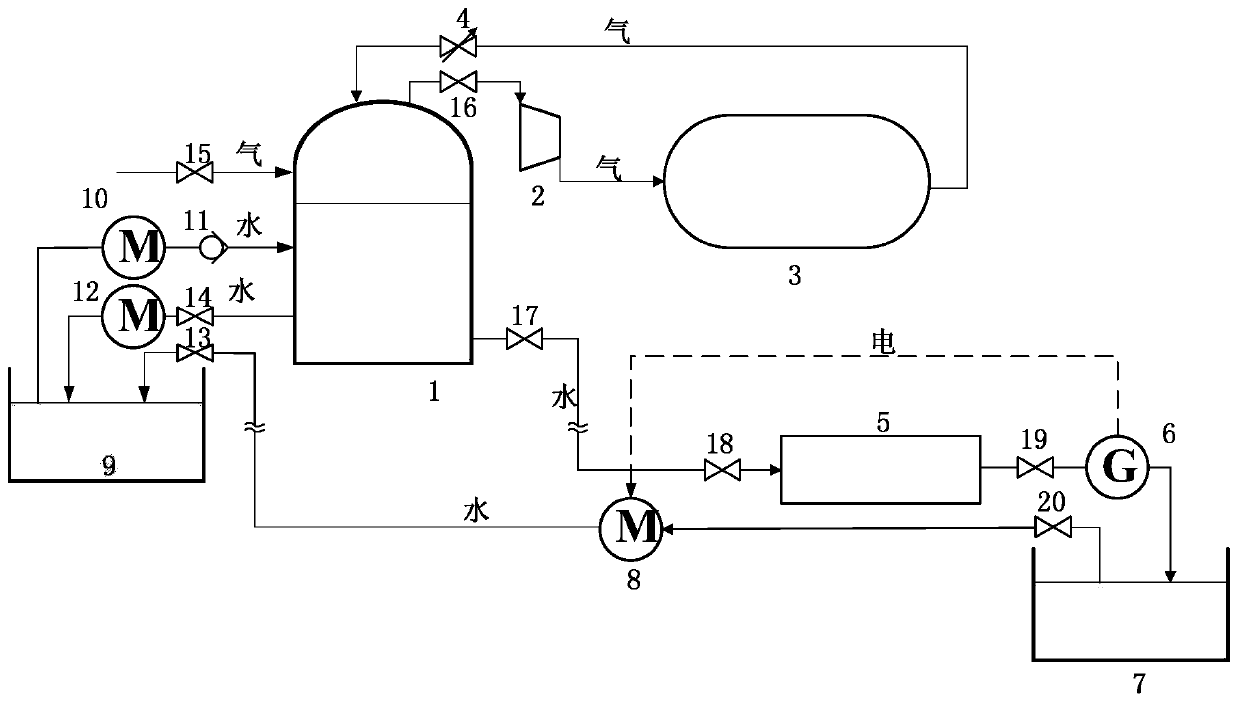

[0041] The present invention is an adjustable ultra-high flow rate and large flow water tunnel system, such as figure 1 As shown, including high-pressure water storage tank 1, booster 2, high-pressure gas storage tank 3, adjustable pressure valve 4, ultra-high-speed test water tunnel 5, water turbine 6, low-level water pool 7, low-pressure water pump 8, high-level water pool 9, high-pressure Water pump 10 and one-way check valve 11;

[0042] Wherein, adopt the parallel system of high-pressure gas storage tank 3 and high-pressure water storage tank 1, this system also includes supercharger 2 and the pressure stabilizing valve 16 in series in the middle; An adjustable pressure valve 4 is set between them to ensure that the high-pressure water storage tank 1 maintains a constant and adjustable ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com